Engineering Design Manual - Loudoun Water

Engineering Design Manual - Loudoun Water

Engineering Design Manual - Loudoun Water

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

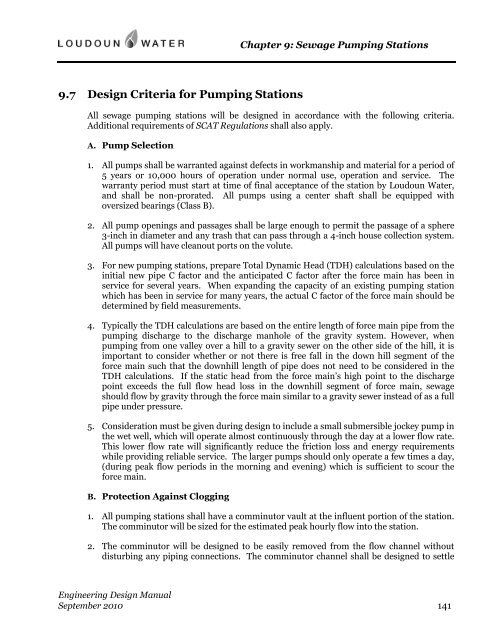

Chapter 9: Sewage Pumping Stations<br />

9.7 <strong>Design</strong> Criteria for Pumping Stations<br />

All sewage pumping stations will be designed in accordance with the following criteria.<br />

Additional requirements of SCAT Regulations shall also apply.<br />

A. Pump Selection<br />

1. All pumps shall be warranted against defects in workmanship and material for a period of<br />

5 years or 10,000 hours of operation under normal use, operation and service. The<br />

warranty period must start at time of final acceptance of the station by <strong>Loudoun</strong> <strong>Water</strong>,<br />

and shall be non-prorated. All pumps using a center shaft shall be equipped with<br />

oversized bearings (Class B).<br />

2. All pump openings and passages shall be large enough to permit the passage of a sphere<br />

3-inch in diameter and any trash that can pass through a 4-inch house collection system.<br />

All pumps will have cleanout ports on the volute.<br />

3. For new pumping stations, prepare Total Dynamic Head (TDH) calculations based on the<br />

initial new pipe C factor and the anticipated C factor after the force main has been in<br />

service for several years. When expanding the capacity of an existing pumping station<br />

which has been in service for many years, the actual C factor of the force main should be<br />

determined by field measurements.<br />

4. Typically the TDH calculations are based on the entire length of force main pipe from the<br />

pumping discharge to the discharge manhole of the gravity system. However, when<br />

pumping from one valley over a hill to a gravity sewer on the other side of the hill, it is<br />

important to consider whether or not there is free fall in the down hill segment of the<br />

force main such that the downhill length of pipe does not need to be considered in the<br />

TDH calculations. If the static head from the force main’s high point to the discharge<br />

point exceeds the full flow head loss in the downhill segment of force main, sewage<br />

should flow by gravity through the force main similar to a gravity sewer instead of as a full<br />

pipe under pressure.<br />

5. Consideration must be given during design to include a small submersible jockey pump in<br />

the wet well, which will operate almost continuously through the day at a lower flow rate.<br />

This lower flow rate will significantly reduce the friction loss and energy requirements<br />

while providing reliable service. The larger pumps should only operate a few times a day,<br />

(during peak flow periods in the morning and evening) which is sufficient to scour the<br />

force main.<br />

B. Protection Against Clogging<br />

1. All pumping stations shall have a comminutor vault at the influent portion of the station.<br />

The comminutor will be sized for the estimated peak hourly flow into the station.<br />

2. The comminutor will be designed to be easily removed from the flow channel without<br />

disturbing any piping connections. The comminutor channel shall be designed to settle<br />

<strong>Engineering</strong> <strong>Design</strong> <strong>Manual</strong><br />

September 2010 141