Highway Slope Manual

Highway Slope Manual

Highway Slope Manual

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

63<br />

qualified and experienced supervisory professionals and competent supporting technical<br />

personnel, especially for supervising potentially hazardous construction activities (e.g.<br />

blasting and rock excavation). The professionals in the contractor's team responsible for<br />

carrying out inspections and assessments to ensure quality of the works and public safety<br />

during construction should be identified. Also, auditing of the contractor's work against<br />

contract requirements, which is a particularly important activity, should be carefully arranged.<br />

This should be carried out by personnel independent of the contractor's site supervisory team<br />

and appointed by the client directly, at critical stages of construction (Works Bureau, 1999d).<br />

Special control testing, including appointment of laboratories independent of the contractor to<br />

carry out the sampling and testing for the critical contract compliance tests (e.g. tests to check<br />

the adequacy of fill slope compaction), should also be arranged by the auditing team for the<br />

client.<br />

7.3 ROCK REMOVAL FROM SLOPES<br />

7.3.1 Rock Breaking Methods<br />

Rock breaking methods commonly used in Hong Kong are listed in Table 7.1. The<br />

choice of the methods is governed by rock strength and structure, groundwater conditions,<br />

safety, and environmental and socio-economic considerations. Fly rock from blasting, and<br />

falling rock blocks and debris from percussive excavation methods are common safety<br />

hazards. Debris falling onto roads can necessitate prolonged road closure with serious socioeconomic<br />

implications. The rockfall during the Tuen Mun <strong>Highway</strong> widening works in<br />

1995 is an illustrative case (Wong, 1997). This case also shows that the use of low energy<br />

methods of rock breaking cannot eliminate all problems since failure can occur along<br />

unknown geological defects. Apart from the fall of debris and rock fragments, dropping of<br />

tools and toppling of construction plant from roadside slopes can also pose a risk to road<br />

users.<br />

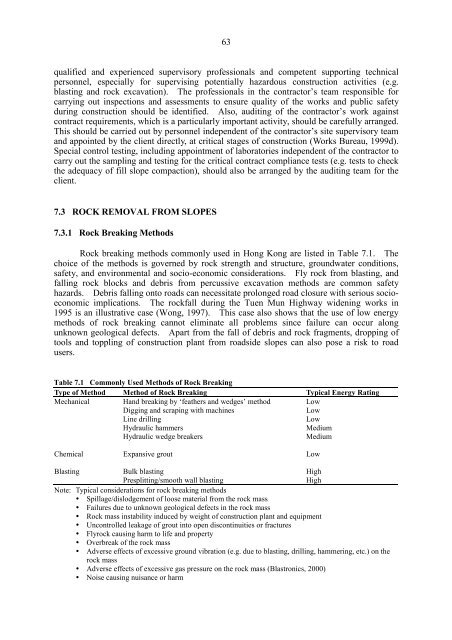

Table 7.1 Commonly Used Methods of Rock Breaking<br />

Type of Method Method of Rock Breaking<br />

Mechanical Hand breaking by ‘feathers and wedges' method<br />

Digging and scraping with machines<br />

Line drilling<br />

Hydraulic hammers<br />

Hydraulic wedge breakers<br />

Typical Energy Rating<br />

Low<br />

Low<br />

Low<br />

Medium<br />

Medium<br />

Chemical Expansive grout Low<br />

Blasting<br />

Bulk blasting<br />

Dresplitting/smooth wall blasting<br />

High<br />

High<br />

Note: Typical considerations for rock breaking methods<br />

• Spillage/dislodgement of loose material from the rock mass<br />

• Failures due to unknown geological defects in the rock mass<br />

• Rock mass instability induced by weight of construction plant and equipment<br />

• Uncontrolled leakage of grout into open discontinuities or fractures<br />

• Flyrock causing harm to life and property<br />

• Overbreak of the rock mass<br />

• Adverse effects of excessive ground vibration (e.g. due to blasting, drilling, hammering, etc.) on the<br />

rock mass<br />

• Adverse effects of excessive gas pressure on the rock mass (Blastronics, 2000)<br />

• Noise causing nuisance or harm