- Page 1 and 2: Medium Voltage Power Cables

- Page 3 and 4: INDEX....... Medium Voltage Cables

- Page 5 and 6: General Information Selecting a Pow

- Page 7: Introduction to XLPE Insulated Cabl

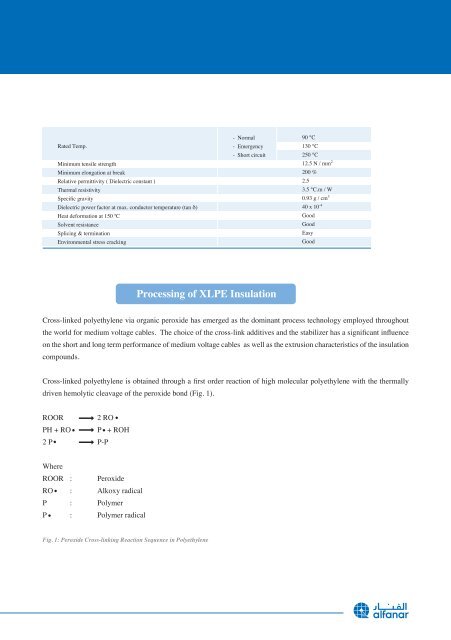

- Page 11 and 12: Design of Medium Voltage Cables The

- Page 13 and 14: Construction of Medium Voltage Cabl

- Page 15 and 16: Construction of Medium Voltage Cabl

- Page 17 and 18: Single-Core Cables, with Copper Con

- Page 19 and 20: Three-Core Cables, with Copper Cond

- Page 21 and 22: Single-Core Cables, with Copper Con

- Page 23 and 24: Three-Core Cables, with Copper Cond

- Page 25 and 26: Single-Core Cables, with Copper Con

- Page 27 and 28: Three-Core Cables, with Copper Cond

- Page 29 and 30: Single-Core Cables, with Aluminum C

- Page 31 and 32: Three-Core Cables, with Aluminum Co

- Page 33 and 34: Single-Core Cables, with Aluminum C

- Page 35 and 36: Three-Core Cables, with Aluminum Co

- Page 37 and 38: Single-Core Cables, with Aluminum C

- Page 39 and 40: Three-Core Cables, with Aluminum Co

- Page 41 and 42: Single-Core Cables, with Copper Con

- Page 43 and 44: Three-Core Cables, with Copper Cond

- Page 45 and 46: Single-Core Cables, with Copper Con

- Page 47 and 48: Three-Core Cables, with Copper Cond

- Page 49 and 50: Single-Core Cables, with Copper Con

- Page 51 and 52: Three-Core Cables, with Copper Cond

- Page 53 and 54: Single-Core Cables, with Aluminum C

- Page 55 and 56: Three-Core Cables, with Aluminum Co

- Page 57 and 58: Single-Core Cables, with Aluminum C

- Page 59 and 60:

Three-Core Cables, with Aluminum Co

- Page 61 and 62:

Single-Core Cables, with Aluminum C

- Page 63 and 64:

Three-Core Cables, with Aluminum Co

- Page 65 and 66:

Single-Core Cables, with Copper Con

- Page 67 and 68:

Three-Core Cables, with Copper Cond

- Page 69 and 70:

Single-Core Cables, with Copper Con

- Page 71 and 72:

Three-Core Cables, with Copper Cond

- Page 73 and 74:

Single-Core Cables, with Copper Con

- Page 75 and 76:

Three-Core Cables, with Copper Cond

- Page 77 and 78:

Single-Core Cables, with Aluminum C

- Page 79 and 80:

Three-Core Cables, with Aluminum Co

- Page 81 and 82:

Single-Core Cables, with Aluminum C

- Page 83 and 84:

Three-Core Cables, with Aluminum Co

- Page 85 and 86:

Single-Core Cables, with Aluminum C

- Page 87 and 88:

Three-Core Cables, with Aluminum Co

- Page 89 and 90:

Single-Core Cables, with Copper Con

- Page 91 and 92:

Three-Core Cables, with Copper Cond

- Page 93 and 94:

Single-Core Cables, with Copper Con

- Page 95 and 96:

Three-Core Cables, with Copper Cond

- Page 97 and 98:

Single-Core Cables, with Copper Con

- Page 99 and 100:

Three-Core Cables, with Copper Cond

- Page 101 and 102:

Single-Core Cables, with Aluminum C

- Page 103 and 104:

Three-Core Cables, with Aluminum Co

- Page 105 and 106:

Single-Core Cables, with Aluminum C

- Page 107 and 108:

Three-Core Cables, with Aluminum Co

- Page 109 and 110:

Single-Core Cables, with Aluminum C

- Page 111 and 112:

Three-Core Cables, with Aluminum Co

- Page 113 and 114:

Single-Core Cables, with Copper Con

- Page 115 and 116:

Three-Core Cables, with Copper Cond

- Page 117 and 118:

Single-Core Cables, with Copper Con

- Page 119 and 120:

Three-Core Cables, with Copper Cond

- Page 121 and 122:

Single-Core Cables, with Copper Con

- Page 123 and 124:

Three-Core Cables, with Copper Cond

- Page 125 and 126:

Single-Core Cables, with Aluminum C

- Page 127 and 128:

Three-Core Cables, with Aluminum Co

- Page 129 and 130:

Single-Core Cables, with Aluminum C

- Page 131 and 132:

Three-Core Cables, with Aluminum Co

- Page 133 and 134:

Single-Core Cables, with Aluminum C

- Page 135 and 136:

Three-Core Cables, with Aluminum Co

- Page 137 and 138:

Cables For Special Applications Lea

- Page 139 and 140:

Annex A: Continuous Current Ratings

- Page 141 and 142:

Annex A: Continuous Current Ratings

- Page 143 and 144:

Annex B: Recommendations B.4.1 Pull

- Page 145 and 146:

Annex B: Recommendations telephone

- Page 147 and 148:

Annex D: Formulas D.1 Resistance Th

- Page 149 and 150:

Annex E: Derating Factors Table E.1

- Page 151 and 152:

Annex E: Derating Factors Table E.6

- Page 153 and 154:

Annex E: Derating Factors Table E.1

- Page 155 and 156:

Annex E: Derating Factors Cables on

- Page 157 and 158:

Annex E: Derating Factors Cables on

- Page 159 and 160:

Annex F: Short Circuit Current Tabl

- Page 161 and 162:

Annex H: Coding Key 1 2 3 4 5 6 7 8

- Page 163 and 164:

Annex J: Conversion Table Multiply

- Page 165 and 166:

Product Range manufactures a wide r

- Page 167:

Contact us markets and sells over 8