2010-11 - Grasim

2010-11 - Grasim

2010-11 - Grasim

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

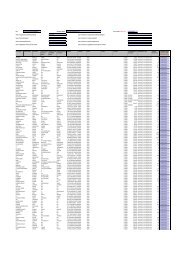

GRASIM BHIWANI<br />

TEXTILES LIMITED<br />

Information pursuant to Section 217 (1) (e) of the Companies Act, 1956<br />

read with Companies (Disclosures of Particulars in the report of Board of<br />

Directors) Rules, 1988 and forming part of the Director’s Report for the<br />

year ending 31 st March, 20<strong>11</strong>.<br />

(A)<br />

(B)<br />

(C)<br />

Conservation of Energy<br />

Some of the initiatives taken in the year <strong>2010</strong>-<strong>11</strong> were as follows:<br />

i) Yarn conditioning steam conversion<br />

ii) Up gradation of Motor Rewinding Technology<br />

iii) Use of energy efficient motors- R/F<br />

iv) Optimisation of Power & Lighting<br />

Total energy consumption and energy consumption per unit of<br />

production : As per Form-A<br />

attached.<br />

Tec<br />

echnology<br />

Absorption<br />

i) Installed an additional humidification plant in weaving so as to<br />

reduce the temperature in sultex section.<br />

ii) Replacement of 10 old suzler looms by 6 new picanol looms.<br />

iii) Two assembly winders installed in Elegant Spinners to produce<br />

polyester viscose stretch yarn.<br />

Foreign Exchange Earnings and Outgo Rs Lacs<br />

<strong>2010</strong>-<strong>11</strong> 2009-10<br />

Foreign exchange earned 7133 5467<br />

Foreign exchange outgo 159 139<br />

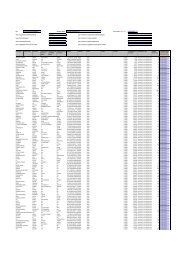

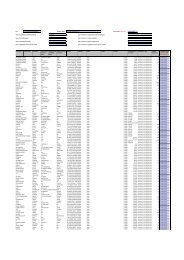

FORM A (Forming part of Annexure<br />

“A”)<br />

DISCLOSURE OF PAR<br />

ARTICULAR<br />

TICULARS WITH RESPECT TO CONSERVATION<br />

OF ENERGY<br />

(A)<br />

POWER & FUEL CONSUMPTION<br />

UOM<br />

Current<br />

rent Year<br />

Pre<br />

revious<br />

Year<br />

1 Electricity<br />

(a)<br />

Purc<br />

urchased<br />

Units ‘000 5297.29 8781.48<br />

Total Amount Lakhs 293.65 391.71<br />

Rate per Unit Rs/ Unit 5.54 4.46<br />

(b)<br />

Own Generation<br />

i) Through Diesel Generator<br />

Units ‘000 813.95 375.76<br />

Unit per Liter of Furnace Oil Unit 3.50 3.29<br />

Cost per Unit (Fuel & Duties Only) Rs/ Unit 8.82 5.13<br />

ii)<br />

Through Steam Turbine<br />

Units ‘000 47358.29 49299.30<br />

Unit per Kg of Steam<br />

Co-generation<br />

of power<br />

& steam<br />

Cost per Unit Rs/ Unit 5.08 4.01<br />

2 Coal/ Pet Coke<br />

For or Steam Generation<br />

Quantity MT 37669.35 39834.77<br />

For Co-generation of Power & Steam MT 34719.85 36586.77<br />

For Steam Coal fired Boiler MT 436.00 391.50<br />

For Fabric Process MT 2513.50 2856.50<br />

Total Amount Rs Lakhs 2662.06 2180.97<br />

Average Rate Rs/ MT 7066.92 5475.05<br />

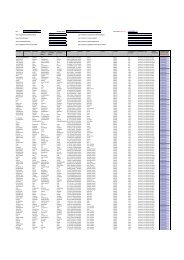

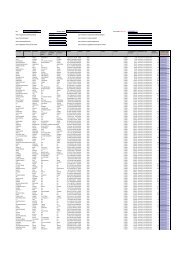

(A)<br />

POWER & FUEL CONSUMPTION<br />

UOM<br />

Current<br />

rent Year<br />

Pre<br />

revious<br />

Year<br />

3 Furnace Oil (Including LSHS)<br />

Quantity K. Ltrs 232.25 141.27<br />

For Power Generation K. Ltrs 232.25 <strong>11</strong>4.27<br />

For Steam Generation K. Ltrs 0.00 2.00<br />

For Fabric Process K. Ltrs 0.00 25.00<br />

Total Amount Rs Lakhs 71.78 26.96<br />

Average Rate Rs/ K. ltr 30908.33 19082.27<br />

4 High Speed Diesel Oil (HSD)<br />

Quantity K. Ltrs 23.46 51.76<br />

Total Amount Rs Lakhs 7.07 15.93<br />

Average Rate Rs/ K. ltr 30135.78 30780.30<br />

5 Internal Generation<br />

(a)<br />

Steam from oil Fired Boiler<br />

Quantity MT 0.00 18.00<br />

Total Amount Rs Lakhs 0.00 0.34<br />

Average Rate Rs/ MT 0.00 1873.44<br />

(b)<br />

Steam from coal Fired Boiler<br />

Quantity MT 3661.00 3177.50<br />

Total Amount Rs Lakhs 36.65 25.<strong>11</strong><br />

Average Rate Rs/ MT 1001.10 790.25<br />

(c)<br />

From Co-generation of Power<br />

& Steam<br />

Quantity MT 39090.76 43513.15<br />

Total Amount Rs Lakhs NA NA<br />

Average Rate Rs/ MT NA NA<br />

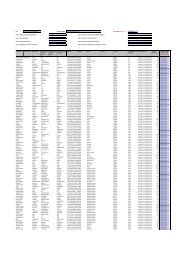

(B)<br />

CONSUMPTION PER UNIT OF PRODUCTION<br />

UOM<br />

Current<br />

rent Year<br />

Pre<br />

revious<br />

Year<br />

1 Electricity<br />

In-house Production<br />

Cloths (Weaved) MT 2598.86 3208.49<br />

Cloths (Processed) MT 5965.60 5700.30<br />

Yarn MT 5544.53 5426.93<br />

Fibre Dyeing MT 2610.84 2466.22<br />

Power Consumption<br />

Cloths (Weaved) Units’ 000 9622.17 10834.22<br />

Cloths (Processed) Units’ 000 5255.26 5536.42<br />

Yarn Units’ 000 34324.39 34269.62<br />

Power Consumption Per Unit<br />

Cloths (Weaved) Units / 100 Kgs 370.25 333.67<br />

Cloths (Processed) Units / 100 Kgs 88.09 97.13<br />

Yarn Units / 100 Kgs 619.07 631.47<br />

2 Steam<br />

Steam Consumption<br />

Cloths (Processed) MT 30636.00 32745.49<br />

Fibre Dyeing MT 12<strong>11</strong>5.76 13963.16<br />

Steam Consumption Per Unit<br />

Cloths (Processed) MT / 100 Kgs 0.51 0.57<br />

Fibre Dyeing MT / 100 Kgs 0.46 0.57<br />

(C)<br />

Power Sale Units’000 4267.70 7816.29<br />

149 ⊳