10 07 29 Master thesis Juliana Leon - e-Waste. This guide

10 07 29 Master thesis Juliana Leon - e-Waste. This guide

10 07 29 Master thesis Juliana Leon - e-Waste. This guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

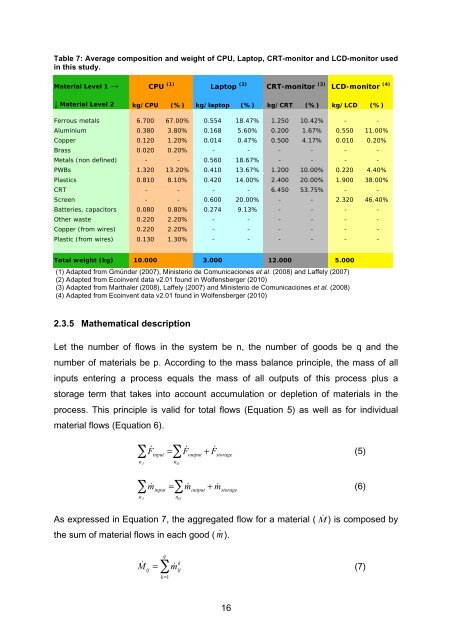

Table 7: Average composition and weight of CPU, Laptop, CRT-monitor and LCD-monitor used<br />

in this study.<br />

Material Level 1 → CPU (1) Laptop (2) CRT-monitor (3) LCD-monitor (4)<br />

↓ Material Level 2 kg/CPU (%) kg/laptop (%) kg/CRT (%) kg/LCD (%)<br />

Ferrous metals 6.700 67.00% 0.554 18.47% 1.250 <strong>10</strong>.42% - -<br />

Aluminium 0.380 3.80% 0.168 5.60% 0.200 1.67% 0.550 11.00%<br />

Copper 0.120 1.20% 0.014 0.47% 0.500 4.17% 0.0<strong>10</strong> 0.20%<br />

Brass 0.020 0.20% - - - - - -<br />

Metals (non defined) - - 0.560 18.67% - - - -<br />

PWBs 1.320 13.20% 0.4<strong>10</strong> 13.67% 1.200 <strong>10</strong>.00% 0.220 4.40%<br />

Plastics 0.8<strong>10</strong> 8.<strong>10</strong>% 0.420 14.00% 2.400 20.00% 1.900 38.00%<br />

CRT - - - - 6.450 53.75% - -<br />

Screen - - 0.600 20.00% - - 2.320 46.40%<br />

Batteries, capacitors 0.080 0.80% 0.274 9.13% - - - -<br />

Other waste 0.220 2.20% - - - - - -<br />

Copper (from wires) 0.220 2.20% - - - - - -<br />

Plastic (from wires) 0.130 1.30% - - - - - -<br />

Total weight (kg) <strong>10</strong>.000 3.000 12.000 5.000<br />

(1) Adapted from Gmünder (20<strong>07</strong>), Ministerio de Comunicaciones et al. (2008) and Laffely (20<strong>07</strong>)<br />

(2) Adapted from Ecoinvent data v2.01 found in Wolfensberger (20<strong>10</strong>)<br />

(3) Adapted from Marthaler (2008), Laffely (20<strong>07</strong>) and Ministerio de Comunicaciones et al. (2008)<br />

(4) Adapted from Ecoinvent data v2.01 found in Wolfensberger (20<strong>10</strong>)<br />

2.3.5 Mathematical description<br />

Let the number of flows in the system be n, the number of goods be q and the<br />

number of materials be p. According to the mass balance principle, the mass of all<br />

inputs entering a process equals the mass of all outputs of this process plus a<br />

storage term that takes into account accumulation or depletion of materials in the<br />

process. <strong>This</strong> principle is valid for total flows (Equation 5) as well as for individual<br />

material flows (Equation 6).<br />

∑<br />

n I<br />

F ˙<br />

input<br />

=<br />

∑ F ˙<br />

output<br />

+ F ˙<br />

storage<br />

(5)<br />

n O<br />

€<br />

∑<br />

n I<br />

m ˙ input<br />

=<br />

∑ m ˙ output<br />

+ m ˙ storage<br />

(6)<br />

n O<br />

As expressed in Equation 7, the aggregated flow for a material ( M ˙ ) is composed by<br />

the sum of material € flows in each good ( m ˙ ).<br />

q<br />

€<br />

M ˙<br />

k<br />

ij<br />

= ∑ m ˙ ij (7)<br />

k =1<br />

€<br />

€<br />

16