10 07 29 Master thesis Juliana Leon - e-Waste. This guide

10 07 29 Master thesis Juliana Leon - e-Waste. This guide

10 07 29 Master thesis Juliana Leon - e-Waste. This guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

where:<br />

i=1,…,n as the index for flows<br />

j=1,…,p as the index for materials<br />

k=1,…,q as the index for goods<br />

We can then sum the different aggregated material flows to obtain the total flow<br />

rates.<br />

p<br />

F ˙<br />

i<br />

= ∑ M ˙<br />

ij<br />

(8)<br />

j =1<br />

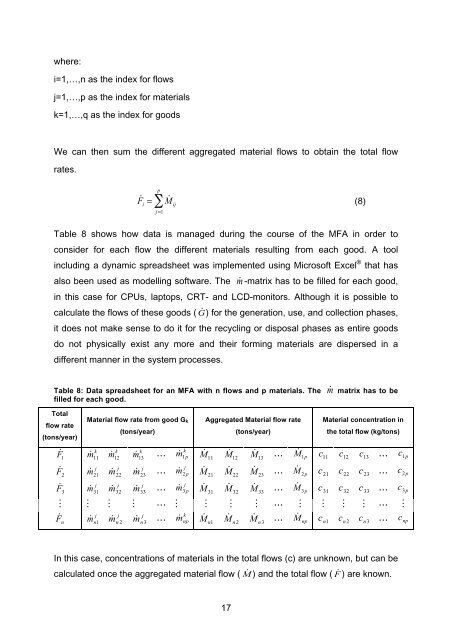

Table 8 shows how data is managed during the course of the MFA in order to<br />

consider for € each flow the different materials resulting from each good. A tool<br />

including a dynamic spreadsheet was implemented using Microsoft Excel ® that has<br />

also been used as modelling software. The m ˙ -matrix has to be filled for each good,<br />

in this case for CPUs, laptops, CRT- and LCD-monitors. Although it is possible to<br />

calculate the flows of these goods ( G ˙ ) for the generation, use, and collection phases,<br />

!<br />

it does not make sense to do it for the recycling or disposal phases as entire goods<br />

do not physically exist any € more and their forming materials are dispersed in a<br />

different manner in the system processes.<br />

Table 8: Data spreadsheet for an MFA with n flows and p materials. The<br />

filled for each good.<br />

˙ m<br />

matrix has to be<br />

€<br />

€<br />

€<br />

€<br />

€<br />

Total<br />

flow rate<br />

(tons/year)<br />

˙ F 1<br />

˙ F 2<br />

˙<br />

€<br />

<br />

€<br />

˙<br />

€<br />

F 3<br />

F n<br />

€<br />

€<br />

€<br />

Material flow rate from good G k<br />

k<br />

m ˙ 11<br />

j<br />

m ˙ 21<br />

k<br />

m ˙ 12<br />

j<br />

m ˙ 22<br />

j<br />

m ˙ 31<br />

€<br />

<br />

€<br />

j<br />

m ˙ n1<br />

˙<br />

€<br />

j<br />

m ˙ 32<br />

(tons/year)<br />

€<br />

j<br />

€<br />

€<br />

€<br />

€<br />

m n 2<br />

k<br />

m ˙ 13<br />

j<br />

m ˙ 23<br />

j<br />

˙<br />

€<br />

<br />

€<br />

j<br />

˙<br />

€<br />

m 33<br />

m n 3<br />

<br />

<br />

<br />

€<br />

<br />

€<br />

<br />

€<br />

k<br />

m ˙ 1p<br />

j<br />

m ˙ 2 p<br />

˙<br />

j<br />

m 3 p<br />

<br />

˙<br />

€<br />

€<br />

k<br />

m np<br />

€<br />

Aggregated Material flow rate<br />

˙ M 11<br />

˙ M 21<br />

˙<br />

M 31<br />

<br />

˙<br />

M n1<br />

€<br />

€<br />

€<br />

˙ M 12<br />

˙ M 22<br />

˙ M 32<br />

(tons/year)<br />

€<br />

€<br />

€<br />

€<br />

€<br />

˙ M 13<br />

˙ M 23<br />

˙<br />

€<br />

<br />

€<br />

˙<br />

€<br />

M 33<br />

<br />

<br />

<br />

<br />

<br />

€<br />

€<br />

€<br />

˙ M 1p<br />

˙ M 2p<br />

˙<br />

€<br />

<br />

˙ €<br />

€<br />

M 3p<br />

Material concentration in<br />

c 11<br />

c 21<br />

c 31<br />

€<br />

<br />

€<br />

€<br />

the total flow (kg/tons)<br />

€ € € € € € € € € € € €<br />

€ In this € case, € concentrations € € of materials € € in the total € flows € (c) are € unknown, € but € can be<br />

calculated once the aggregated material flow ( M ˙ ) and the total flow ( F ˙ ) are known.<br />

<br />

˙<br />

M n 2<br />

M n 3<br />

!<br />

M np<br />

c n1<br />

c 12<br />

c 22<br />

c 32<br />

€ <br />

€<br />

€<br />

€<br />

€<br />

c n 2<br />

c 13<br />

c 23<br />

c 33<br />

€<br />

<br />

€<br />

c n 3<br />

€<br />

<br />

<br />

<br />

<br />

<br />

c 1p<br />

c 2 p<br />

c 3 p<br />

<br />

c np<br />

€<br />

17<br />

€