Eurotubi Pressfitting System - Technical Guide ... - Damstahl

Eurotubi Pressfitting System - Technical Guide ... - Damstahl

Eurotubi Pressfitting System - Technical Guide ... - Damstahl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

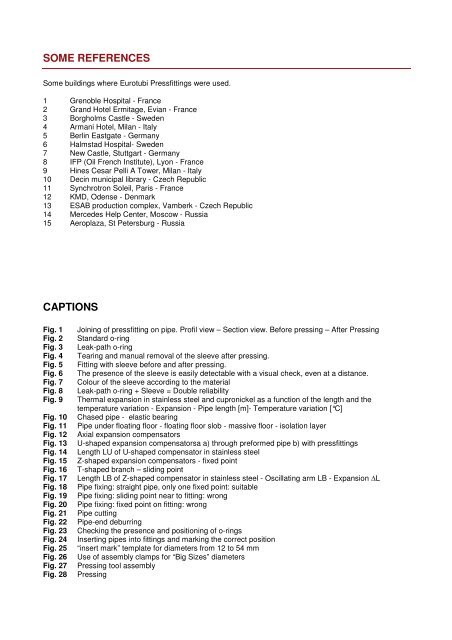

SOME REFERENCES<br />

Some buildings where <strong>Eurotubi</strong> <strong>Pressfitting</strong>s were used.<br />

1 Grenoble Hospital - France<br />

2 Grand Hotel Ermitage, Evian - France<br />

3 Borgholms Castle - Sweden<br />

4 Armani Hotel, Milan - Italy<br />

5 Berlin Eastgate - Germany<br />

6 Halmstad Hospital- Sweden<br />

7 New Castle, Stuttgart - Germany<br />

8 IFP (Oil French Institute), Lyon - France<br />

9 Hines Cesar Pelli A Tower, Milan - Italy<br />

10 Decin municipal library - Czech Republic<br />

11 Synchrotron Soleil, Paris - France<br />

12 KMD, Odense - Denmark<br />

13 ESAB production complex, Vamberk - Czech Republic<br />

14 Mercedes Help Center, Moscow - Russia<br />

15 Aeroplaza, St Petersburg - Russia<br />

CAPTIONS<br />

Fig. 1<br />

Fig. 2<br />

Fig. 3<br />

Fig. 4<br />

Fig. 5<br />

Fig. 6<br />

Fig. 7<br />

Fig. 8<br />

Fig. 9<br />

Fig. 10<br />

Fig. 11<br />

Fig. 12<br />

Fig. 13<br />

Fig. 14<br />

Fig. 15<br />

Fig. 16<br />

Fig. 17<br />

Fig. 18<br />

Fig. 19<br />

Fig. 20<br />

Fig. 21<br />

Fig. 22<br />

Fig. 23<br />

Fig. 24<br />

Fig. 25<br />

Fig. 26<br />

Fig. 27<br />

Fig. 28<br />

Joining of pressfitting on pipe. Profil view – Section view. Before pressing – After Pressing<br />

Standard o-ring<br />

Leak-path o-ring<br />

Tearing and manual removal of the sleeve after pressing.<br />

Fitting with sleeve before and after pressing.<br />

The presence of the sleeve is easily detectable with a visual check, even at a distance.<br />

Colour of the sleeve according to the material<br />

Leak-path o-ring + Sleeve = Double reliability<br />

Thermal expansion in stainless steel and cupronickel as a function of the length and the<br />

temperature variation - Expansion - Pipe length [m]- Temperature variation [°C]<br />

Chased pipe - elastic bearing<br />

Pipe under floating floor - floating floor slob - massive floor - isolation layer<br />

Axial expansion compensators<br />

U-shaped expansion compensatorsa a) through preformed pipe b) with pressfittings<br />

Length LU of U-shaped compensator in stainless steel<br />

Z-shaped expansion compensators - fixed point<br />

T-shaped branch – sliding point<br />

Length LB of Z-shaped compensator in stainless steel - Oscillating arm LB - Expansion ∆L<br />

Pipe fixing: straight pipe, only one fixed point: suitable<br />

Pipe fixing: sliding point near to fitting: wrong<br />

Pipe fixing: fixed point on fitting: wrong<br />

Pipe cutting<br />

Pipe-end deburring<br />

Checking the presence and positioning of o-rings<br />

Inserting pipes into fittings and marking the correct position<br />

“insert mark” template for diameters from 12 to 54 mm<br />

Use of assembly clamps for “Big Sizes” diameters<br />

Pressing tool assembly<br />

Pressing