REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

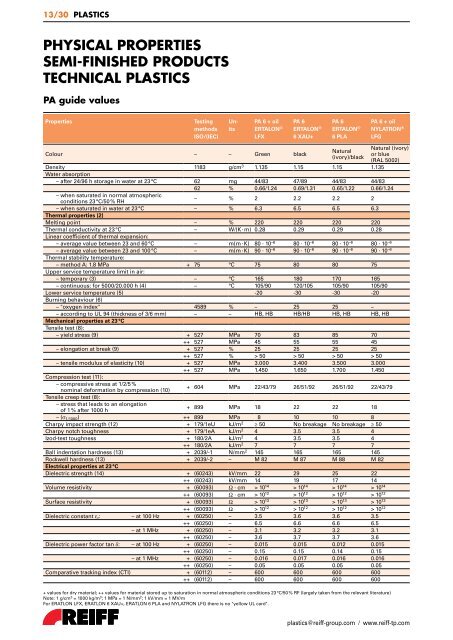

13/30 <strong>PLASTICS</strong><br />

PHYSICAL PROPERTIES<br />

SEMI-FINISHED PRODUCTS<br />

TECHNICAL <strong>PLASTICS</strong><br />

PA guide values<br />

Properties Testing Un- PA 6 + oil PA 6 PA 6 PA 6 + oil<br />

methods its ERTALON ® ERTALON ® ERTALON ® NYLATRON ®<br />

ISO/(IEC) LFX 6 XAU+ 6 PLA LFG<br />

Colour – – Green black<br />

Natural<br />

(ivory)/black<br />

Natural (ivory)<br />

or blue<br />

(RAL 5002)<br />

Density 1183 g/cm3 Water absorption<br />

1.135 1.15 1.15 1.135<br />

– after 24/96 h storage in water at 23 °C 62 mg 44/83 47/89 44/83 44/83<br />

62 % 0.66/1.24 0.69/1.31 0.65/1.22 0.66/1.24<br />

– when saturated in normal atmospheric<br />

conditions 23 °C/50 % RH<br />

– % 2 2.2 2.2 2<br />

– when saturated in water at 23 °C<br />

Thermal properties (2)<br />

– % 6.3 6.5 6.5 6.3<br />

Melting point – % 220 220 220 220<br />

Thermal conductivity at 23 °C<br />

Linear coefficient of thermal expansion:<br />

– W/(K · m) 0.28 0.29 0.29 0.28<br />

– average value between 23 and 60 °C – m(m · K) 80 · 10 –6 80 · 10 –6 80 · 10 –6 80 · 10 –6<br />

– average value between 23 and 100 °C – m(m · K) 90 · 10 –6 90 · 10 –6 90 · 10 –6 90 · 10 –6<br />

Thermal stability temperature:<br />

– method A: 1.8 MPa<br />

Upper service temperature limit in air:<br />

+ 75 °C 75 80 80 75<br />

– temporary (3) – °C 165 180 170 165<br />

– continuous: for 5000/20.000 h (4) – °C 105/90 120/105 105/90 105/90<br />

Lower service temperature (5)<br />

Burning behaviour (6)<br />

-20 -30 -30 -20<br />

– "oxygen index" 4589 % – 25 25 –<br />

– according to UL 94 (thickness of 3/6 mm)<br />

Mechanical properties at 23 °C<br />

Tensile test (8):<br />

– – HB, HB HB/HB HB, HB HB, HB<br />

– yield stress (9) + 527 MPa 70 83 85 70<br />

++ 527 MPa 45 55 55 45<br />

– elongation at break (9) + 527 % 25 25 25 25<br />

++ 527 % > 50 > 50 > 50 > 50<br />

– tensile modulus of elasticity (10) + 527 MPa 3.000 3.400 3.500 3.000<br />

Compression test (11):<br />

++ 527 MPa 1.450 1.650 1.700 1.450<br />

– compressive stress at 1/2/5 %<br />

nominal deformation by compression (10)<br />

Tensile creep test (8):<br />

+ 604 MPa 22/43/79 26/51/92 26/51/92 22/43/79<br />

– stress that leads to an elongation<br />

of 1 % after 1000 h<br />

+ 899 MPa 18 22 22 18<br />

– (�1/1000) ++ 899 MPa 8 10 10 8<br />

Charpy impact strength (12) + 179/1eU kJ/m2 ≥ 50 No breakage No breakage ≥ 50<br />

Charpy notch toughness + 179/1eA kJ/m2 4 3.5 3.5 4<br />

Izod-test toughness + 180/2A kJ/m2 4 3.5 3.5 4<br />

++ 180/2A kJ/m2 7 7 7 7<br />

Ball indentation hardness (13) + 2039/-1 N/mm2 145 165 165 145<br />

Rockwell hardness (13)<br />

Electrical properties at 23 °C<br />

+ 2039/-2 – M 82 M 87 M 88 M 82<br />

Dielectric strength (14) + (60243) kV/mm 22 29 25 22<br />

++ (60243) kV/mm 14 19 17 14<br />

Volume resistivity + (60093) Ω · cm > 1014 > 1014 > 1014 > 1014 ++ (60093) Ω · cm > 1012 > 1012 > 1012 > 1012 Surface resistivity + (60093) Ω > 1013 > 1013 > 1013 > 1013 ++ (60093) Ω > 1012 > 1012 > 1012 > 1012 Dielectric constant εr: – at 100 Hz + (60250) – 3.5 3.6 3.6 3.5<br />

++ (60250) – 6.5 6.6 6.6 6.5<br />

– at 1 MHz + (60250) – 3.1 3.2 3.2 3.1<br />

++ (60250) – 3.6 3.7 3.7 3.6<br />

Dielectric power factor tan �: – at 100 Hz + (60250) – 0.015 0.015 0.012 0.015<br />

++ (60250) – 0.15 0.15 0.14 0.15<br />

– at 1 MHz + (60250) – 0.016 0.017 0.016 0.016<br />

++ (60250) – 0.05 0.05 0.05 0.05<br />

Comparative tracking index (CTI) + (60112) – 600 600 600 600<br />

++ (60112) – 600 600 600 600<br />

+ values for dry material; ++ values for material stored up to saturation in normal atmospheric conditions 23 °C/50 % RF (largely taken from the relevant literature)<br />

Note: 1 g/cm 3 = 1000 kg/m 3 ; 1 MPa = 1 N/mm 2 ; 1 kV/mm = 1 MV/m<br />

For ERATLON LFX, ERATLON 6 XAU+, ERATLON 6 PLA and NYLATRON LFG there is no "yellow UL card".<br />

plastics@reiff-group.com / www.reiff-tp.com