REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

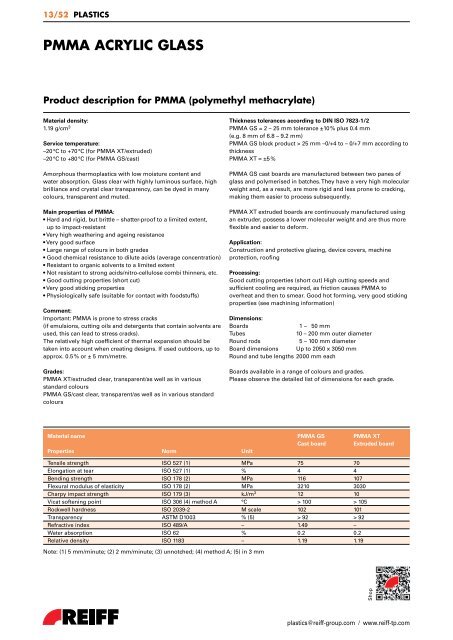

13/52 <strong>PLASTICS</strong><br />

PMMA ACRYLIC GLASS<br />

Product description for PMMA (polymethyl methacrylate)<br />

Material density:<br />

1.19 g/cm 3<br />

Service temperature:<br />

–20 °C to +70 °C (for PMMA XT/extruded)<br />

–20 °C to +80 °C (for PMMA GS/cast)<br />

Amorphous thermoplastics with low moisture content and<br />

water absorption. Glass clear with highly luminous surface, high<br />

brilliance and crystal clear transparency, can be dyed in many<br />

colours, transparent and muted.<br />

Main properties of PMMA:<br />

• Hard and rigid, but brittle – shatter-proof to a limited extent,<br />

up to impact-resistant<br />

• Very high weathering and ageing resistance<br />

• Very good surface<br />

• Large range of colours in both grades<br />

• Good chemical resistance to dilute acids (average concentration)<br />

• Resistant to organic solvents to a limited extent<br />

• Not resistant to strong acids/nitro-cellulose combi thinners, etc.<br />

• Good cutting properties (short cut)<br />

• Very good sticking properties<br />

• Physiologically safe (suitable for contact with foodstuffs)<br />

Comment:<br />

Important: PMMA is prone to stress cracks<br />

(if emulsions, cutting oils and detergents that contain solvents are<br />

used, this can lead to stress cracks).<br />

The relatively high coefficient of thermal expansion should be<br />

taken into account when creating designs. If used outdoors, up to<br />

approx. 0.5 % or ± 5 mm/metre.<br />

Grades:<br />

PMMA XT/extruded clear, transparent/as well as in various<br />

standard colours<br />

PMMA GS/cast clear, transparent/as well as in various standard<br />

colours<br />

Thickness tolerances according to DIN ISO 7823-1/2<br />

PMMA GS = 2 – 25 mm tolerance ±10 % plus 0.4 mm<br />

(e.g. 8 mm of 6.8 – 9.2 mm)<br />

PMMA GS block product > 25 mm –0/+4 to – 0/+7 mm according to<br />

thickness<br />

PMMA XT = ±5 %<br />

PMMA GS cast boards are manufactured between two panes of<br />

glass and polymerised in batches. They have a very high molecular<br />

weight and, as a result, are more rigid and less prone to cracking,<br />

making them easier to process subsequently.<br />

PMMA XT extruded boards are continuously manufactured using<br />

an extruder, possess a lower molecular weight and are thus more<br />

flexible and easier to deform.<br />

Application:<br />

Construction and protective glazing, device covers, machine<br />

protection, roofing<br />

Processing:<br />

Good cutting properties (short cut) High cutting speeds and<br />

sufficient cooling are required, as friction causes PMMA to<br />

overheat and then to smear. Good hot forming, very good sticking<br />

properties (see machining information)<br />

Dimensions:<br />

Boards 1 – 50 mm<br />

Tubes 10 – 200 mm outer diameter<br />

Round rods 5 – 100 mm diameter<br />

Board dimensions Up to 2050 x 3050 mm<br />

Round and tube lengths 2000 mm each<br />

Boards available in a range of colours and grades.<br />

Please observe the detailed list of dimensions for each grade.<br />

Material name PMMA GS PMMA XT<br />

Cast board Extruded board<br />

Properties Norm Unit<br />

Tensile strength ISO 527 (1) MPa 75 70<br />

Elongation at tear ISO 527 (1) % 4 4<br />

Bending strength ISO 178 (2) MPa 116 107<br />

Flexural modulus of elasticity ISO 178 (2) MPa 3210 3030<br />

Charpy impact strength ISO 179 (3) kJ/m 3 12 10<br />

Vicat softening point ISO 306 (4) method A °C > 100 > 105<br />

Rockwell hardness ISO 2039-2 M scale 102 101<br />

Transparency ASTM D1003 % (5) > 92 > 92<br />

Refractive index ISO 489/A – 1.49 –<br />

Water absorption ISO 62 % 0.2 0.2<br />

Relative density ISO 1183 – 1.19 1.19<br />

Note: (1) 5 mm/minute; (2) 2 mm/minute; (3) unnotched; (4) method A; (5) in 3 mm<br />

Shop<br />

plastics@reiff-group.com / www.reiff-tp.com