REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

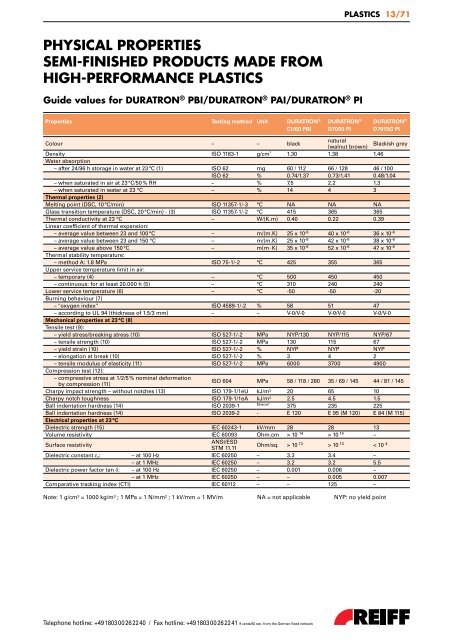

PHYSICAL PROPERTIES<br />

SEMI-FINISHED PRODUCTS MADE FROM<br />

HIGH-PERFORMANCE <strong>PLASTICS</strong><br />

Guide values for DURATRON ® PBI/DURATRON ® PAI/DURATRON ® PI<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/71<br />

Properties Testing method Unit DURATRON ® DURATRON ® DURATRON ®<br />

CU60 PBI D7000 PI D7015G PI<br />

Colour – – black<br />

natural<br />

(walnut brown)<br />

Blackish grey<br />

Density ISO 1183-1 g/cm ³ Water absorption<br />

1.30 1.38 1.46<br />

– after 24/96 h storage in water at 23 °C (1) ISO 62 mg 60 / 112 66 / 128 46 / 100<br />

ISO 62 % 0.74/1.37 0.73/1.41 0.48/1.04<br />

– when saturated in air at 23 °C/50 % RH – % 7.5 2.2 1.3<br />

– when saturated in water at 23 °C<br />

Thermal properties (2)<br />

– % 14 4 3<br />

Melting point (DSC, 10 °C/min) ISO 11357-1/-3 °C NA NA NA<br />

Glass transition temperature (DSC, 20 °C/min) - (3) ISO 11357-1/-2 °C 415 365 365<br />

Thermal conductivity at 23 °C<br />

Linear coefficient of thermal expansion:<br />

– W/(K.m) 0.40 0.22 0.39<br />

– average value between 23 and 100 °C – m/(m.K) 25 x 10-6 40 x 10-6 36 x 10-6 – average value between 23 and 150 °C – m/(m.K) 25 x 10-6 42 x 10-6 38 x 10-6 – average value above 150 °C – m(m · K) 35 x 10-6 52 x 10-6 47 x 10-6 Thermal stability temperature:<br />

– method A: 1.8 MPa<br />

Upper service temperature limit in air:<br />

ISO 75-1/-2 °C 425 355 365<br />

– temporary (4) – °C 500 450 450<br />

– continuous: for at least 20.000 h (5) – °C 310 240 240<br />

Lower service temperature (6)<br />

Burning behaviour (7)<br />

– °C -50 -50 -20<br />

– "oxygen index" ISO 4589-1/-2 % 58 51 47<br />

– according to UL 94 (thickness of 1.5/3 mm)<br />

Mechanical properties at 23 °C (8)<br />

Tensile test (9):<br />

– – V-0/V-0 V-0/V-0 V-0/V-0<br />

– yield stress/breaking stress (10) ISO 527-1/-2 MPa NYP/130 NYP/115 NYP/67<br />

– tensile strength (10) ISO 527-1/-2 MPa 130 115 67<br />

– yield strain (10) ISO 527-1/-2 % NYP NYP NYP<br />

– elongation at break (10) ISO 527-1/-2 % 3 4 2<br />

– tensile modulus of elasticity (11)<br />

Compression test (12):<br />

ISO 527-1/-2 MPa 6000 3700 4900<br />

– compressive stress at 1/2/5 % nominal deformation<br />

by compression (11)<br />

ISO 604 MPa 58 / 118 / 280 35 / 69 / 145 44 / 81 / 145<br />

Charpy impact strength – without notches (13) ISO 179-1/1eU kJ/m² 20 65 10<br />

Charpy notch toughness ISO 179-1/1eA kJ/m² 2.5 4.5 1.5<br />

Ball indentation hardness (14) ISO 2039-1 N/mm² 375 235 225<br />

Ball indentation hardness (14)<br />

Electrical properties at 23 °C<br />

ISO 2039-2 - E 120 E 95 (M 120) E 84 (M 115)<br />

Dielectric strength (15) IEC 60243-1 kV/mm 28 28 13<br />

Volume resistivity IEC 60093 Ohm.cm > 10 14 > 10 14 –<br />

Surface resistivity<br />

ANSI/ESD<br />

STM 11.11<br />

Ohm/sq. > 10 13 > 10 13 < 10 4<br />

Dielectric constant εr: – at 100 Hz IEC 60250 – 3.3 3.4 –<br />

– at 1 MHz IEC 60250 – 3.2 3.2 5.5<br />

Dielectric power factor tan �: – at 100 Hz IEC 60250 – 0.001 0.006 –<br />

– at 1 MHz IEC 60250 – – 0.005 0.007<br />

Comparative tracking index (CTI) IEC 60112 – – 125 –<br />

Note: 1 g/cm³ = 1000 kg/m³ ; 1 MPa = 1 N/mm² ; 1 kV/mm = 1 MV/m NA = not applicable NYP: no yield point