REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PTFE<br />

Properties of PTFE (polytetrafluoroethylene)<br />

Material density:<br />

2.2 – 2.3 g/cm 3<br />

Service temperature:<br />

-200 to +260/280 °C (20.000 hours/temporary)<br />

Temporary = only a few hours, where no or only low loads may<br />

occur<br />

Fluorosint ® grades:<br />

Also offer excellent mechanical properties (rigidity/creep strength,<br />

wear resistance) paired with outstanding chemical resistance.<br />

Main properties of PTFE:<br />

• High upper continuous service temperature limit in air 260 °C<br />

• Almost universal chemical resistance<br />

• Excellent chemical and hydrolysis resistance<br />

• Very high anti-adhesion level<br />

• Outstanding UV and weather resistance<br />

• Good electrical insulating properties<br />

• Non-filled grades are physiologically safe<br />

• Good mechanical stressability<br />

• Incombustibility according to UL standard<br />

• Very low coefficient of friction<br />

Comment:<br />

If heated to temperatures above 320 °C, PTFE can lose gaseous<br />

decomposition products, some of which are toxic.<br />

Due to their outstanding chemical resistance, PTFE films/boards<br />

do not stick without being etched on one side. (Please indicate if<br />

sticking may be necessary when ordering.)<br />

Grade: PTFE colour (white)<br />

Modified PTFE = PTFE with glass<br />

= PTFE with carbon<br />

= PTFE with graphite<br />

= PTFE with bronze<br />

PTFE etched on one side (can be stuck)<br />

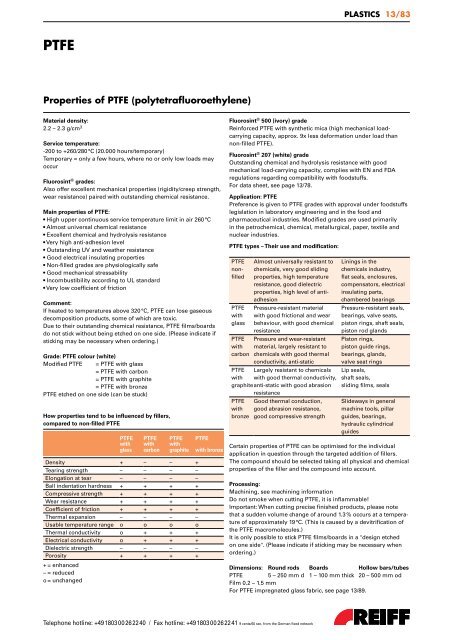

How properties tend to be influenced by fillers,<br />

compared to non-filled PTFE<br />

+ = enhanced<br />

– = reduced<br />

o = unchanged<br />

PTFE PTFE PTFE PTFE<br />

with<br />

glass<br />

with<br />

carbon<br />

with<br />

graphite with bronze<br />

Density + – – +<br />

Tearing strength – – – –<br />

Elongation at tear – – – –<br />

Ball indentation hardness + + + +<br />

Compressive strength + + + +<br />

Wear resistance + + + +<br />

Coefficient of friction + + + +<br />

Thermal expansion – – – –<br />

Usable temperature range o o o o<br />

Thermal conductivity o + + +<br />

Electrical conductivity o + + +<br />

Dielectric strength – – – –<br />

Porosity + + + +<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/83<br />

Fluorosint ® 500 (ivory) grade<br />

Reinforced PTFE with synthetic mica (high mechanical loadcarrying<br />

capacity, approx. 9x less deformation under load than<br />

non-filled PTFE).<br />

Fluorosint ® 207 (white) grade<br />

Outstanding chemical and hydrolysis resistance with good<br />

mechanical load-carrying capacity, complies with EN and FDA<br />

regulations regarding compatibility with foodstuffs.<br />

For data sheet, see page 13/78.<br />

Application: PTFE<br />

Preference is given to PTFE grades with approval under foodstuffs<br />

legislation in laboratory engineering and in the food and<br />

pharmaceutical industries. Modified grades are used primarily<br />

in the petrochemical, chemical, metallurgical, paper, textile and<br />

nuclear industries.<br />

PTFE types – Their use and modification:<br />

PTFE<br />

nonfilled<br />

PTFE<br />

with<br />

glass<br />

PTFE<br />

with<br />

carbon<br />

Almost universally resistant to<br />

chemicals, very good sliding<br />

properties, high temperature<br />

resistance, good dielectric<br />

properties, high level of antiadhesion<br />

Pressure-resistant material<br />

with good frictional and wear<br />

behaviour, with good chemical<br />

resistance<br />

Pressure and wear-resistant<br />

material, largely resistant to<br />

chemicals with good thermal<br />

conductivity, anti-static<br />

PTFE Largely resistant to chemicals<br />

with with good thermal conductivity,<br />

graphiteanti-static<br />

with good abrasion<br />

resistance<br />

PTFE Good thermal conduction,<br />

with good abrasion resistance,<br />

bronze good compressive strength<br />

Linings in the<br />

chemicals industry,<br />

flat seals, enclosures,<br />

compensators, electrical<br />

insulating parts,<br />

chambered bearings<br />

Pressure-resistant seals,<br />

bearings, valve seats,<br />

piston rings, shaft seals,<br />

piston rod glands<br />

Piston rings,<br />

piston guide rings,<br />

bearings, glands,<br />

valve seat rings<br />

Lip seals,<br />

shaft seals,<br />

sliding films, seals<br />

Slideways in general<br />

machine tools, pillar<br />

guides, bearings,<br />

hydraulic cylindrical<br />

guides<br />

Certain properties of PTFE can be optimised for the individual<br />

application in question through the targeted addition of fillers.<br />

The compound should be selected taking all physical and chemical<br />

properties of the filler and the compound into account.<br />

Processing:<br />

Machining, see machining information<br />

Do not smoke when cutting PTFE, it is inflammable!<br />

Important: When cutting precise finished products, please note<br />

that a sudden volume change of around 1.3 % occurs at a temperature<br />

of approximately 19 °C. (This is caused by a devitrification of<br />

the PTFE macromolecules.)<br />

It is only possible to stick PTFE films/boards in a "design etched<br />

on one side". (Please indicate if sticking may be necessary when<br />

ordering.)<br />

Dimensions: Round rods Boards Hollow bars/tubes<br />

PTFE 5 – 250 mm d 1 – 100 mm thick 20 – 500 mm od<br />

Film 0.2 – 1.5 mm<br />

For PTFE impregnated glass fabric, see page 13/89.