REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

13/54 <strong>PLASTICS</strong><br />

PC MAKROLON ®<br />

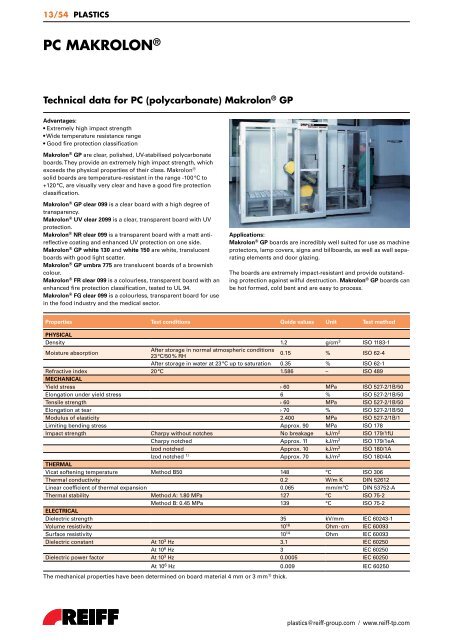

Technical data for PC (polycarbonate) Makrolon ® GP<br />

Advantages:<br />

• Extremely high impact strength<br />

• Wide temperature resistance range<br />

• Good fire protection classification<br />

Makrolon ® GP are clear, polished, UV-stabilised polycarbonate<br />

boards. They provide an extremely high impact strength, which<br />

exceeds the physical properties of their class. Makrolon ®<br />

solid boards are temperature-resistant in the range -100 °C to<br />

+120 °C, are visually very clear and have a good fire protection<br />

classification.<br />

Makrolon ® GP clear 099 is a clear board with a high degree of<br />

transparency.<br />

Makrolon ® UV clear 2099 is a clear, transparent board with UV<br />

protection.<br />

Makrolon ® NR clear 099 is a transparent board with a matt antireflective<br />

coating and enhanced UV protection on one side.<br />

Makrolon ® GP white 130 and white 150 are white, translucent<br />

boards with good light scatter.<br />

Makrolon ® GP umbra 775 are translucent boards of a brownish<br />

colour.<br />

Makrolon ® FR clear 099 is a colourless, transparent board with an<br />

enhanced fire protection classification, tested to UL 94.<br />

Makrolon ® FG clear 099 is a colourless, transparent board for use<br />

in the food industry and the medical sector.<br />

Applications:<br />

Makrolon ® GP boards are incredibly well suited for use as machine<br />

protectors, lamp covers, signs and billboards, as well as wall separating<br />

elements and door glazing.<br />

The boards are extremely impact-resistant and provide outstanding<br />

protection against wilful destruction. Makrolon ® GP boards can<br />

be hot formed, cold bent and are easy to process.<br />

Properties Test conditions Guide values Unit Test method<br />

The mechanical properties have been determined on board material 4 mm or 3 mm1) PHYSICAL<br />

Density 1.2 g/cm<br />

thick.<br />

3 ISO 1183-1<br />

Moisture absorption<br />

After storage in normal atmospheric conditions<br />

23 °C/50 % RH<br />

0.15 % ISO 62-4<br />

After storage in water at 23 °C up to saturation 0.35 % ISO 62-1<br />

Refractive index<br />

MECHANICAL<br />

20 °C 1.586 – ISO 489<br />

Yield stress › 60 MPa ISO 527-2/1B/50<br />

Elongation under yield stress 6 % ISO 527-2/1B/50<br />

Tensile strength › 60 MPa ISO 527-2/1B/50<br />

Elongation at tear › 70 % ISO 527-2/1B/50<br />

Modulus of elasticity 2.400 MPa ISO 527-2/1B/1<br />

Limiting bending stress Approx. 90 MPa ISO 178<br />

Impact strength Charpy without notches No breakage kJ/m2 ISO 179/1fU<br />

Charpy notched Approx. 11 kJ/m2 ISO 179/1eA<br />

Izod notched Approx. 10 kJ/m2 ISO 180/1A<br />

Izod notched 1) Approx. 70 kJ/m2 THERMAL<br />

ISO 180/4A<br />

Vicat softening temperature Method B50 148 °C ISO 306<br />

Thermal conductivity 0.2 W/m K DIN 52612<br />

Linear coefficient of thermal expansion 0.065 mm/m°C DIN 53752-A<br />

Thermal stability Method A: 1.80 MPa 127 °C ISO 75-2<br />

ELECTRICAL<br />

Method B: 0.45 MPa 139 °C ISO 75-2<br />

Dielectric strength 35 kV/mm IEC 60243-1<br />

Volume resistivity 1016 Ohm · cm IEC 60093<br />

Surface resistivity 1014 Ohm IEC 60093<br />

Dielectric constant At 103 Hz 3.1 IEC 60250<br />

At 106 Hz 3 IEC 60250<br />

Dielectric power factor At 103 Hz 0.0005 IEC 60250<br />

At 106 Hz 0.009 IEC 60250<br />

plastics@reiff-group.com / www.reiff-tp.com