REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

REGISTER OVERVIEW PLASTICS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

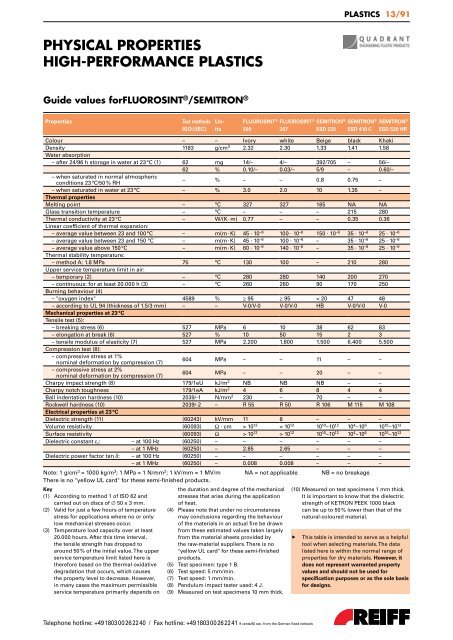

PHYSICAL PROPERTIES<br />

HIGH-PERFORMANCE <strong>PLASTICS</strong><br />

Guide values forFLUOROSINT ® /SEMITRON ®<br />

Telephone hotline: +49 1803 00 26 22 40 / Fax hotline: +49 1803 00 26 22 41 9 cents/60 sec. from the German fixed network<br />

<strong>PLASTICS</strong> 13/91<br />

Properties Test methods Un- FLUOROSINT ® FLUOROSINT ® SEMITRON ® SEMITRON ® SEMITRON ®<br />

ISO/(IEC) its 500 207 ESD 225 ESD 410 C ESD 520 HR<br />

Colour – – Ivory white Beige black Khaki<br />

Density 1183 g/cm3 Water absorption<br />

2.32 2.30 1.33 1.41 1.58<br />

– after 24/96 h storage in water at 23 °C (1) 62 mg 14/– 4/– 392/705 – 56/–<br />

62 % 0.10/– 0.03/– 5/9 – 0.60/–<br />

– when saturated in normal atmospheric<br />

conditions 23 °C/50 % RH<br />

– % – – 0.8 0.75 –<br />

– when saturated in water at 23 °C<br />

Thermal properties<br />

– % 3.0 2.0 10 1.35 –<br />

Melting point – °C 327 327 165 NA NA<br />

Glass transition temperature – °C – – – 215 280<br />

Thermal conductivity at 23 °C<br />

Linear coefficient of thermal expansion:<br />

– W/(K · m) 0.77 – – 0.35 0.36<br />

– average value between 23 and 100 °C – m(m · K) 45 · 10 –6 100 · 10 –6 150 · 10 –6 35 · 10 –6 25 · 10 –6<br />

– average value between 23 and 150 °C – m(m · K) 45 · 10 –6 100 · 10 –6 – 35 · 10 –6 25 · 10 –6<br />

– average value above 150 °C – m(m · K) 60 · 10 –6 140 · 10 –6 – 35 · 10 –6 25 · 10 –6<br />

Thermal stability temperature:<br />

– method A: 1.8 MPa<br />

Upper service temperature limit in air:<br />

75 °C 130 100 – 210 280<br />

– temporary (2) – °C 280 280 140 200 270<br />

– continuous: for at least 20.000 h (3)<br />

Burning behaviour (4)<br />

– °C 260 260 90 170 250<br />

– "oxygen index" 4589 % ≥ 95 ≥ 95 < 20 47 48<br />

– according to UL 94 (thickness of 1.5/3 mm)<br />

Mechanical properties at 23 °C<br />

Tensile test (5):<br />

– – V-0/V-0 V-0/V-0 HB V-0/V-0 V-0<br />

– breaking stress (6) 527 MPa 6 10 38 62 83<br />

– elongation at break (6) 527 % 10 50 15 2 3<br />

– tensile modulus of elasticity (7)<br />

Compression test (8):<br />

527 MPa 2.200 1.800 1.500 6.400 5.500<br />

– compressive stress at 1%<br />

nominal deformation by compression (7)<br />

604 MPa – – 11 – –<br />

– compressive stress at 2%<br />

nominal deformation by compression (7)<br />

604 MPa – – 20 – –<br />

Charpy impact strength (8) 179/1eU kJ/m2 NB NB NB – –<br />

Charpy notch toughness 179/1eA kJ/m2 4 6 8 4 4<br />

Ball indentation hardness (10) 2039/-1 N/mm2 230 – 70 – –<br />

Rockwell hardness (10)<br />

Electrical properties at 23 °C<br />

2039/-2 – R 55 R 50 R 106 M 115 M 108<br />

Dielectric strength (11) (60243) kV/mm 11 8 – – –<br />

Volume resistivity (60093) Ω · cm > 1012 > 1012 10 10 – 1012 104 – 106 10 10 – 1012 Surface resistivity (60093) Ω > 1012 > 1012 10 10 – 1012 104 – 106 10 10 – 1012 Dielectric constant εr: – at 100 Hz (60250) – – – – – –<br />

– at 1 MHz (60250) – 2.85 2.65 – – –<br />

Dielectric power factor tan δ: – at 100 Hz (60250) – – – – – –<br />

– at 1 MHz (60250) – 0.008 0.008 – – –<br />

Note: 1 g/cm3 = 1000 kg/m3 ; 1 MPa = 1 N/mm2 ; 1 kV/mm = 1 MV/m NA = not applicable NB = no breakage<br />

There is no "yellow UL card" for these semi-finished products.<br />

Key<br />

(1) According to method 1 of ISO 62 and<br />

carried out on discs of ∅ 50 x 3 mm.<br />

(2) Valid for just a few hours of temperature<br />

stress for applications where no or only<br />

low mechanical stresses occur.<br />

(3) Temperature load capacity over at least<br />

20.000 hours. After this time interval,<br />

the tensile strength has dropped to<br />

around 50 % of the initial value. The upper<br />

service temperature limit listed here is<br />

therefore based on the thermal oxidative<br />

degradation that occurs, which causes<br />

the property level to decrease. However,<br />

in many cases the maximum permissible<br />

service temperature primarily depends on<br />

the duration and degree of the mechanical<br />

stresses that arise during the application<br />

of heat.<br />

(4) Please note that under no circumstances<br />

may conclusions regarding the behaviour<br />

of the materials in an actual fire be drawn<br />

from these estimated values taken largely<br />

from the material sheets provided by<br />

the raw-material suppliers. There is no<br />

"yellow UL card" for these semi-finished<br />

products.<br />

(5) Test specimen: type 1 B.<br />

(6) Test speed: 5 mm/min.<br />

(7) Test speed: 1 mm/min.<br />

(8) Pendulum impact tester used: 4 J.<br />

(9) Measured on test specimens 10 mm thick.<br />

(10) Measured on test specimens 1 mm thick.<br />

It is important to know that the dielectric<br />

strength of KETRON PEEK 1000 black<br />

can be up to 50 % lower than that of the<br />

natural-coloured material.<br />

� This table is intended to serve as a helpful<br />

tool when selecting materials. The data<br />

listed here is within the normal range of<br />

properties for dry materials. However, it<br />

does not represent warranted property<br />

values and should not be used for<br />

specification purposes or as the sole basis<br />

for designs.