Catalogue 2010

Catalogue 2010

Catalogue 2010

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1|Generating compressed air<br />

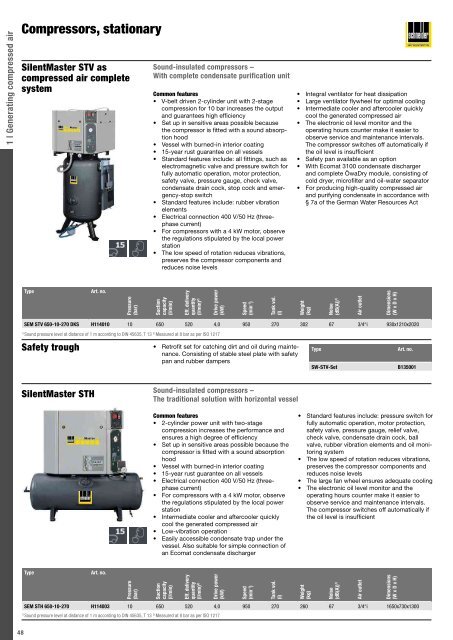

SilentMaster STV as<br />

compressed air complete<br />

system<br />

48<br />

Compressors, stationary<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

Sound-insulated compressors –<br />

With complete condensate purification unit<br />

Common features<br />

• V-belt driven 2-cylinder unit with 2-stage<br />

compression for 10 bar increases the output<br />

and guarantees high efficiency<br />

• Set up in sensitive areas possible because<br />

the compressor is fitted with asound absorption<br />

hood<br />

• Vessel with burned-in interior coating<br />

• 15-year rust guarantee on all vessels<br />

• Standard features include: all fittings, such as<br />

electromagnetic valve and pressure switch for<br />

fully automatic operation, motor protection,<br />

safety valve, pressure gauge, check valve,<br />

condensate drain cock, stop cock and emergency-stop<br />

switch<br />

• Standard features include: rubber vibration<br />

elements<br />

• Electrical connection 400 V/50 Hz (threephase<br />

current)<br />

• For compressors with a4kWmotor, observe<br />

the regulations stipulated by the local power<br />

station<br />

• The low speed of rotation reduces vibrations,<br />

preserves the compressor components and<br />

reduces noise levels<br />

Suction<br />

capacity<br />

(l/min)<br />

Eff. delivery<br />

quantity<br />

(l/min) 2)<br />

Drive power<br />

(kW)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

• Integral ventilator for heat dissipation<br />

• Large ventilator flywheel for optimal cooling<br />

• Intermediate cooler and aftercooler quickly<br />

cool the generated compressed air<br />

• The electronic oil level monitor and the<br />

operating hours counter make it easier to<br />

observe service and maintenance intervals.<br />

The compressor switches off automatically if<br />

the oil level is insufficient<br />

• Safety pan available as an option<br />

• With Ecomat 3100 condensate discharger<br />

and complete ÖwaDry module, consisting of<br />

cold dryer, microfilter and oil-water separator<br />

• For producing high-quality compressed air<br />

and purifying condensate in accordance with<br />

§7aofthe German Water Resources Act<br />

SEM STV 650-10-270 DKS H114010 10 650 520 4,0 950 270 302 67 3/4“i 930x1210x2020<br />

1) Sound pressure level at distance of 1maccording to DIN 45635, T13 2) Measured at 8bar as per ISO 1217<br />

Safety trough • Retrofit set for catching dirt and oil during mainte- Type Art. no.<br />

SilentMaster STH<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

nance. Consisting of stable steel plate with safety<br />

pan and rubber dampers<br />

Sound-insulated compressors –<br />

The traditional solution with horizontal vessel<br />

Common features<br />

• 2-cylinder power unit with two-stage<br />

compression increases the performance and<br />

ensures ahigh degree of efficiency<br />

• Set up in sensitive areas possible because the<br />

compressor is fitted with asound absorption<br />

hood<br />

• Vessel with burned-in interior coating<br />

• 15-year rust guarantee on all vessels<br />

• Electrical connection 400 V/50 Hz (threephase<br />

current)<br />

• For compressors with a4kWmotor, observe<br />

the regulations stipulated by the local power<br />

station<br />

• Intermediate cooler and aftercooler quickly<br />

cool the generated compressed air<br />

• Low-vibration operation<br />

• Easily accessible condensate trap under the<br />

vessel. Also suitable for simple connection of<br />

an Ecomat condensate discharger<br />

Suction<br />

capacity<br />

(l/min)<br />

Eff. delivery<br />

quantity<br />

(l/min) 2)<br />

Drive power<br />

(kW)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A)) 1)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)<br />

SW-STV-Set B135001<br />

• Standard features include: pressure switch for<br />

fully automatic operation, motor protection,<br />

safety valve, pressure gauge, relief valve,<br />

check valve, condensate drain cock, ball<br />

valve, rubber vibration elements and oil monitoring<br />

system<br />

• The low speed of rotation reduces vibrations,<br />

preserves the compressor components and<br />

reduces noise levels<br />

• The large fan wheel ensures adequate cooling<br />

• The electronic oil level monitor and the<br />

operating hours counter make it easier to<br />

observe service and maintenance intervals.<br />

The compressor switches off automatically if<br />

the oil level is insufficient<br />

SEM STH 650-10-270 H114003 10 650 520 4,0 950 270 260 67 3/4“i 1650x730x1300<br />

1) Sound pressure level at distance of 1maccording to DIN 45635, T13 2) Measured at 8bar as per ISO 1217<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A)) 1)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)