Catalogue 2010

Catalogue 2010

Catalogue 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1|Generating compressed air<br />

Compressors, stationary<br />

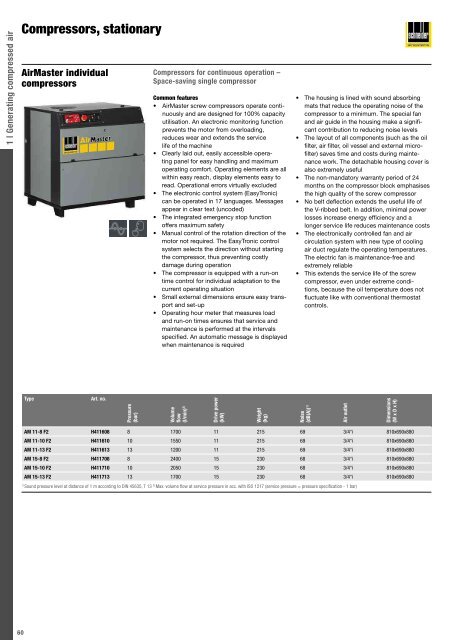

AirMaster individual<br />

compressors<br />

60<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

Compressors for continuous operation –<br />

Space-saving single compressor<br />

Common features<br />

• AirMaster screw compressors operate continuously<br />

and are designed for 100% capacity<br />

utilisation. An electronic monitoring function<br />

prevents the motor from overloading,<br />

reduces wear and extends the service<br />

life of the machine<br />

• Clearly laid out, easily accessible operating<br />

panel for easy handling and maximum<br />

operating comfort. Operating elements are all<br />

within easy reach, display elements easy to<br />

read. Operational errors virtually excluded<br />

• The electronic control system (EasyTronic)<br />

can be operated in 17 languages. Messages<br />

appear in clear text (uncoded)<br />

• The integrated emergency stop function<br />

offers maximum safety<br />

• Manual control of the rotation direction of the<br />

motor not required. The EasyTronic control<br />

system selects the direction without starting<br />

the compressor, thus preventing costly<br />

damage during operation<br />

• The compressor is equipped with arun-on<br />

time control for individual adaptation to the<br />

current operating situation<br />

• Small external dimensions ensure easy transport<br />

and set-up<br />

• Operating hour meter that measures load<br />

and run-on times ensures that service and<br />

maintenance is performed at the intervals<br />

specified. An automatic message is displayed<br />

when maintenance is required<br />

Volume<br />

flow<br />

(l/min) 2)<br />

Drive power<br />

(kW)<br />

Weight<br />

(kg)<br />

• The housing is lined with sound absorbing<br />

mats that reduce the operating noise of the<br />

compressor to aminimum. The special fan<br />

and air guide in the housing make asignificant<br />

contribution to reducing noise levels<br />

• The layout of all components (such as the oil<br />

filter, air filter, oil vessel and external microfilter)<br />

saves time and costs during maintenance<br />

work. The detachable housing cover is<br />

also extremely useful<br />

• The non-mandatory warranty period of 24<br />

months on the compressor block emphasises<br />

the high quality of the screw compressor<br />

• Nobelt deflection extends the useful life of<br />

the V-ribbed belt. In addition, minimal power<br />

losses increase energy efficiency and a<br />

longer service life reduces maintenance costs<br />

• The electronically controlled fan and air<br />

circulation system with new type of cooling<br />

air duct regulate the operating temperatures.<br />

The electric fan is maintenance-free and<br />

extremely reliable<br />

• This extends the service life of the screw<br />

compressor, even under extreme conditions,<br />

because the oil temperature does not<br />

fluctuate like with conventional thermostat<br />

controls.<br />

AM 11-8 F2 H411608 8 1700 11 215 69 3/4“i 810x690x880<br />

AM 11-10 F2 H411610 10 1550 11 215 69 3/4“i 810x690x880<br />

AM 11-13 F2 H411613 13 1200 11 215 69 3/4“i 810x690x880<br />

AM 15-8 F2 H411708 8 2400 15 230 68 3/4“i 810x690x880<br />

AM 15-10 F2 H411710 10 2050 15 230 68 3/4“i 810x690x880<br />

AM 15-13 F2 H411713 13 1700 15 230 68 3/4“i 810x690x880<br />

1) Sound pressure level at distance of 1maccording to DIN 45635, T13 2) Max. volume flowatservice pressure in acc. with ISO 1217 (service pressure =pressure specification -1bar)<br />

Noise<br />

(dB(A)) 1)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)