Catalogue 2010

Catalogue 2010

Catalogue 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

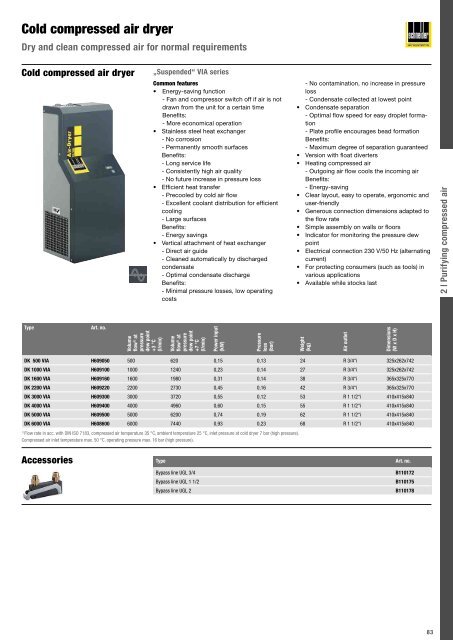

Cold compressed air dryer<br />

Dry and clean compressed air for normal requirements<br />

Cold compressed air dryer<br />

Type Art. no.<br />

Volume<br />

flow1) at<br />

pressure<br />

dew point<br />

+3 °C<br />

(l/min)<br />

„Suspended“ VIA series<br />

Common features<br />

• Energy-saving function<br />

-Fan and compressor switch off ifair is not<br />

drawn from the unit for acertain time<br />

Benefits:<br />

-More economical operation<br />

• Stainless steel heat exchanger<br />

-Nocorrosion<br />

-Permanently smooth surfaces<br />

Benefits:<br />

-Long service life<br />

-Consistently high air quality<br />

-Nofuture increase in pressure loss<br />

• Efficient heat transfer<br />

-Precooled by cold air flow<br />

-Excellent coolant distribution for efficient<br />

cooling<br />

-Large surfaces<br />

Benefits:<br />

-Energy savings<br />

• Vertical attachment of heat exchanger<br />

-Direct air guide<br />

-Cleaned automatically by discharged<br />

condensate<br />

-Optimal condensate discharge<br />

Benefits:<br />

-Minimal pressure losses, low operating<br />

costs<br />

Volume<br />

flow1) at<br />

pressure<br />

dew point<br />

+7 °C<br />

(l/min)<br />

Power input<br />

(kW)<br />

Pressure<br />

loss<br />

(bar)<br />

-Nocontamination, no increase in pressure<br />

loss<br />

-Condensate collected at lowest point<br />

• Condensate separation<br />

-Optimal flow speed for easy droplet formation<br />

-Plate profile encourages bead formation<br />

Benefits:<br />

-Maximum degree of separation guaranteed<br />

• Version with float diverters<br />

• Heating compressed air<br />

-Outgoing air flow cools the incoming air<br />

Benefits:<br />

-Energy-saving<br />

• Clear layout, easy to operate, ergonomic and<br />

user-friendly<br />

• Generous connection dimensions adapted to<br />

the flow rate<br />

• Simple assembly on walls or floors<br />

• Indicator for monitoring the pressure dew<br />

point<br />

• Electrical connection 230 V/50 Hz (alternating<br />

current)<br />

• For protecting consumers (such as tools) in<br />

various applications<br />

• Available while stocks last<br />

DK 500 VIA H609050 500 620 0,15 0,13 24 R3/4“i 325x262x742<br />

DK 1000 VIA H609100 1000 1240 0,23 0,14 27 R3/4“i 325x262x742<br />

DK 1600 VIA H609160 1600 1980 0,31 0,14 38 R3/4“i 365x325x770<br />

DK 2200 VIA H609220 2200 2730 0,45 0,16 42 R3/4“i 365x325x770<br />

DK 3000 VIA H609300 3000 3720 0,55 0,12 53 R11/2“i 410x415x840<br />

DK 4000 VIA H609400 4000 4960 0,60 0,15 55 R11/2“i 410x415x840<br />

DK 5000 VIA H609500 5000 6200 0,74 0,19 62 R11/2“i 410x415x840<br />

DK 6000 VIA H608600 6000 7440 0,93 0,23 68 R11/2“i 410x415x840<br />

1) Flowrateinacc. with DIN ISO 7183, compressed air temperature 35 °C, ambient temperature 25 °C, inlet pressure at cold dryer 7bar (high pressure).<br />

Compressed air inlet temperature max. 50 °C, operating pressure max. 16 bar (high pressure).<br />

Accessories Type Art. no.<br />

Bypass line UGL 3/4 B110172<br />

Bypass line UGL 11/2 B110175<br />

Bypass line UGL 2 B110178<br />

Weight<br />

(kg)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)<br />

83<br />

2|Purifying compressed air