Catalogue 2010

Catalogue 2010

Catalogue 2010

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2|Purifying compressed air<br />

84<br />

Cold compressed air dryer<br />

Dry and clean compressed air for normal requirements<br />

Cold compressed air dryer<br />

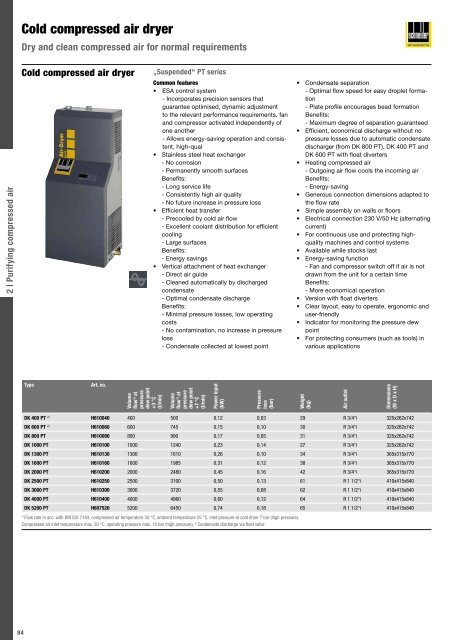

Type Art. no.<br />

Volume<br />

flow1) at<br />

pressure<br />

dew point<br />

+3 °C<br />

(l/min)<br />

„Suspended“ PT series<br />

Common features<br />

• ESA control system<br />

-Incorporates precision sensors that<br />

guarantee optimised, dynamic adjustment<br />

to the relevant performance requirements, fan<br />

and compressor activated independently of<br />

one another<br />

-Allows energy-saving operation and consistent,<br />

high-qual<br />

• Stainless steel heat exchanger<br />

-Nocorrosion<br />

-Permanently smooth surfaces<br />

Benefits:<br />

-Long service life<br />

-Consistently high air quality<br />

-Nofuture increase in pressure loss<br />

• Efficient heat transfer<br />

-Precooled by cold air flow<br />

-Excellent coolant distribution for efficient<br />

cooling<br />

-Large surfaces<br />

Benefits:<br />

-Energy savings<br />

• Vertical attachment of heat exchanger<br />

-Direct air guide<br />

-Cleaned automatically by discharged<br />

condensate<br />

-Optimal condensate discharge<br />

Benefits:<br />

-Minimal pressure losses, low operating<br />

costs<br />

-Nocontamination, no increase in pressure<br />

loss<br />

-Condensate collected at lowest point<br />

Volume<br />

flow1) at<br />

pressure<br />

dew point<br />

+7 °C<br />

(l/min)<br />

Power input<br />

(kW)<br />

Pressure<br />

loss<br />

(bar)<br />

• Condensate separation<br />

-Optimal flow speed for easy droplet formation<br />

-Plate profile encourages bead formation<br />

Benefits:<br />

-Maximum degree of separation guaranteed<br />

• Efficient, economical discharge without no<br />

pressure losses due to automatic condensate<br />

discharger (from DK 800 PT). DK 400 PT and<br />

DK 600 PT with float diverters<br />

• Heating compressed air<br />

-Outgoing air flow cools the incoming air<br />

Benefits:<br />

-Energy-saving<br />

• Generous connection dimensions adapted to<br />

the flow rate<br />

• Simple assembly on walls or floors<br />

• Electrical connection 230 V/50 Hz (alternating<br />

current)<br />

• For continuous use and protecting highquality<br />

machines and control systems<br />

• Available while stocks last<br />

• Energy-saving function<br />

-Fan and compressor switch off ifair is not<br />

drawn from the unit for acertain time<br />

Benefits:<br />

-More economical operation<br />

• Version with float diverters<br />

• Clear layout, easy to operate, ergonomic and<br />

user-friendly<br />

• Indicator for monitoring the pressure dew<br />

point<br />

• For protecting consumers (such as tools) in<br />

various applications<br />

DK 400 PT 2) H610040 400 500 0,12 0,03 29 R3/4“i 325x262x742<br />

DK 600 PT 2) H610060 600 745 0,15 0,10 30 R3/4“i 325x262x742<br />

DK 800 PT H610080 800 990 0,17 0,05 31 R3/4“i 325x262x742<br />

DK 1000 PT H610100 1000 1240 0,23 0,14 27 R3/4“i 325x262x742<br />

DK 1300 PT H610130 1300 1610 0,26 0,10 34 R3/4“i 365x315x770<br />

DK 1600 PT H610160 1600 1985 0,31 0,12 38 R3/4“i 365x315x770<br />

DK 2000 PT H610200 2000 2480 0,45 0,16 42 R3/4“i 365x315x770<br />

DK 2500 PT H610250 2500 3100 0,50 0,13 61 R11/2“i 410x415x840<br />

DK 3000 PT H610300 3000 3720 0,55 0,08 62 R11/2“i 410x415x840<br />

DK 4000 PT H610400 4000 4960 0,60 0,12 64 R11/2“i 410x415x840<br />

DK 5200 PT H607520 5200 6450 0,74 0,18 65 R11/2“i 410x415x840<br />

1) Flowrateinacc. with DIN ISO 7183, compressed air temperature 35 °C, ambient temperature 25 °C, inlet pressure at cold dryer 7bar (high pressure).<br />

Compressed air inlet temperature max. 50 °C, operating pressure max. 16 bar (high pressure). 2) Condensate discharge via floatvalve<br />

Weight<br />

(kg)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)