Catalogue 2010

Catalogue 2010

Catalogue 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

1|Generating compressed air<br />

Compressors, stationary<br />

54<br />

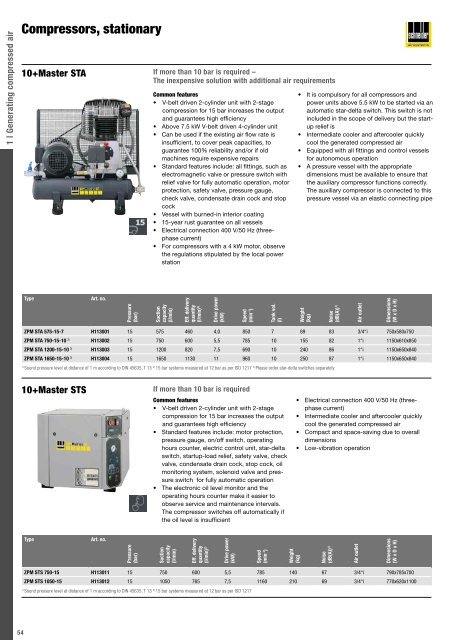

10+Master STA<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

If more than 10 bar is required –<br />

The inexpensive solution with additional air requirements<br />

Common features<br />

• V-belt driven 2-cylinder unit with 2-stage<br />

compression for 15 bar increases the output<br />

and guarantees high efficiency<br />

• Above 7.5 kW V-belt driven 4-cylinder unit<br />

• Can be used if the existing air flow rate is<br />

insufficient, to cover peak capacities, to<br />

guarantee 100% reliability and/or if old<br />

machines require expensive repairs<br />

• Standard features include: all fittings, such as<br />

electromagnetic valve or pressure switch with<br />

relief valve for fully automatic operation, motor<br />

protection, safety valve, pressure gauge,<br />

check valve, condensate drain cock and stop<br />

cock<br />

• Vessel with burned-in interior coating<br />

• 15-year rust guarantee on all vessels<br />

• Electrical connection 400 V/50 Hz (threephase<br />

current)<br />

• For compressors with a4kWmotor, observe<br />

the regulations stipulated by the local power<br />

station<br />

Suction<br />

capacity<br />

(l/min)<br />

Eff. delivery<br />

quantity<br />

(l/min) 2)<br />

Drive power<br />

(kW)<br />

Speed<br />

(min-1 )<br />

Tank vol.<br />

(l)<br />

• Itiscompulsory for all compressors and<br />

power units above 5.5 kW to be started via an<br />

automatic star-delta switch. This switch is not<br />

included in the scope of delivery but the startup<br />

relief is<br />

• Intermediate cooler and aftercooler quickly<br />

cool the generated compressed air<br />

• Equipped with all fittings and control vessels<br />

for autonomous operation<br />

• A pressure vessel with the appropriate<br />

dimensions must be available to ensure that<br />

the auxiliary compressor functions correctly.<br />

The auxiliary compressor is connected to this<br />

pressure vessel via an elastic connecting pipe<br />

ZPM STA 575-15-7 H113001 15 575 460 4,0 850 7 89 83 3/4“i 750x580x750<br />

ZPM STA 750-15-10 3) H113002 15 750 600 5,5 785 10 155 82 1“i 1150x610x850<br />

ZPM STA 1200-15-10 3) H113003 15 1200 820 7,5 690 10 240 86 1“i 1150x650x840<br />

ZPM STA 1650-15-10 3) H113004 15 1650 1130 11 960 10 250 87 1“i 1150x650x840<br />

1) Sound pressure level at distance of 1maccording to DIN 45635, T13 2) 15 bar systems measured at 12 bar as per ISO 1217 3) Please order star-delta switches separately<br />

10+Master STS<br />

Type Art. no.<br />

Pressure<br />

(bar)<br />

If more than 10 bar is required<br />

Common features<br />

• V-belt driven 2-cylinder unit with 2-stage<br />

compression for 15 bar increases the output<br />

and guarantees high efficiency<br />

• Standard features include: motor protection,<br />

pressure gauge, on/off switch, operating<br />

hours counter, electric control unit, star-delta<br />

switch, startup-load relief, safety valve, check<br />

valve, condensate drain cock, stop cock, oil<br />

monitoring system, solenoid valve and pressure<br />

switch for fully automatic operation<br />

• The electronic oil level monitor and the<br />

operating hours counter make it easier to<br />

observe service and maintenance intervals.<br />

The compressor switches off automatically if<br />

the oil level is insufficient<br />

Suction<br />

capacity<br />

(l/min)<br />

Eff. delivery<br />

quantity<br />

(l/min) 2)<br />

Drive power<br />

(kW)<br />

Speed<br />

(min-1 )<br />

Weight<br />

(kg)<br />

Weight<br />

(kg)<br />

Noise<br />

(dB(A)) 1)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)<br />

• Electrical connection 400 V/50 Hz (threephase<br />

current)<br />

• Intermediate cooler and aftercooler quickly<br />

cool the generated compressed air<br />

• Compact and space-saving due to overall<br />

dimensions<br />

• Low-vibration operation<br />

ZPM STS 750-15 H113011 15 750 600 5,5 785 140 67 3/4“i 790x785x700<br />

ZPM STS 1050-15 H113012 15 1050 765 7,5 1160 210 69 3/4“i 770x620x1100<br />

1) Sound pressure level at distance of 1maccording to DIN 45635, T13 2) 15 bar systems measured at 12 bar as per ISO 1217<br />

Noise<br />

(dB(A)) 1)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)