Catalogue 2010

Catalogue 2010

Catalogue 2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2|Purifying compressed air<br />

86<br />

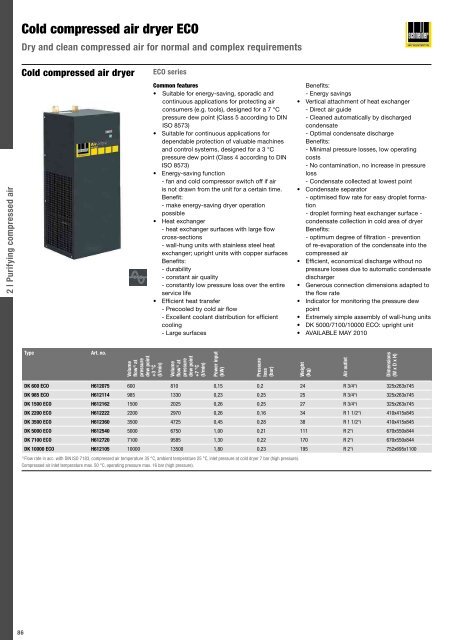

Cold compressed air dryer ECO<br />

Dry and clean compressed air for normal and complex requirements<br />

Cold compressed air dryer<br />

Type Art. no.<br />

Volume<br />

flow1) at<br />

pressure<br />

dew point<br />

+3 °C<br />

(l/min)<br />

ECO series<br />

Common features<br />

• Suitable for energy-saving, sporadic and<br />

continuous applications for protecting air<br />

consumers (e.g. tools), designed for a7°C<br />

pressure dew point (Class 5according to DIN<br />

ISO 8573)<br />

• Suitable for continuous applications for<br />

dependable protection of valuable machines<br />

and control systems, designed for a3°C<br />

pressure dew point (Class 4according to DIN<br />

ISO 8573)<br />

• Energy-saving function<br />

-fan and cold compressor switch off ifair<br />

is not drawn from the unit for acertain time.<br />

Benefit:<br />

-make energy-saving dryer operation<br />

possible<br />

• Heat exchanger<br />

-heat exchanger surfaces with large flow<br />

cross-sections<br />

-wall-hung units with stainless steel heat<br />

exchanger; upright units with copper surfaces<br />

Benefits:<br />

-durability<br />

-constant air quality<br />

-constantly low pressure loss over the entire<br />

service life<br />

• Efficient heat transfer<br />

-Precooled by cold air flow<br />

-Excellent coolant distribution for efficient<br />

cooling<br />

-Large surfaces<br />

Volume<br />

flow1) at<br />

pressure<br />

dew point<br />

+7 °C<br />

(l/min)<br />

Power input<br />

(kW)<br />

Pressure<br />

loss<br />

(bar)<br />

Benefits:<br />

-Energy savings<br />

• Vertical attachment of heat exchanger<br />

-Direct air guide<br />

-Cleaned automatically by discharged<br />

condensate<br />

-Optimal condensate discharge<br />

Benefits:<br />

-Minimal pressure losses, low operating<br />

costs<br />

-Nocontamination, no increase in pressure<br />

loss<br />

-Condensate collected at lowest point<br />

• Condensate separator<br />

-optimised flow rate for easy droplet formation<br />

-droplet forming heat exchanger surface -<br />

condensate collection in cold area of dryer<br />

Benefits:<br />

-optimum degree of filtration -prevention<br />

of re-evaporation of the condensate into the<br />

compressed air<br />

• Efficient, economical discharge without no<br />

pressure losses due to automatic condensate<br />

discharger<br />

• Generous connection dimensions adapted to<br />

the flow rate<br />

• Indicator for monitoring the pressure dew<br />

point<br />

• Extremely simple assembly of wall-hung units<br />

• DK5000/7100/10000 ECO: upright unit<br />

• AVAILABLE MAY <strong>2010</strong><br />

DK 600 ECO H612075 600 810 0,15 0,2 24 R3/4“i 325x263x745<br />

DK 985 ECO H612114 985 1330 0,23 0,25 25 R3/4“i 325x263x745<br />

DK 1500 ECO H612162 1500 2025 0,26 0,25 27 R3/4“i 325x263x745<br />

DK 2200 ECO H612222 2200 2970 0,26 0,16 34 R11/2“i 410x415x845<br />

DK 3500 ECO H612360 3500 4725 0,45 0,28 38 R11/2“i 410x415x845<br />

DK 5000 ECO H612540 5000 6750 1,00 0,21 111 R2“i 670x550x844<br />

DK 7100 ECO H612720 7100 9585 1,30 0,22 170 R2“i 670x550x844<br />

DK 10000 ECO H612105 10000 13500 1,80 0,23 195 R2“i 752x695x1100<br />

1) Flowrateinacc. with DIN ISO 7183, compressed air temperature 35 °C, ambient temperature 25 °C, inlet pressure at cold dryer 7bar (high pressure).<br />

Compressed air inlet temperature max. 50 °C, operating pressure max. 16 bar (high pressure).<br />

Weight<br />

(kg)<br />

Air outlet<br />

Dimensions<br />

(W xDxH)