CAGE PROCESSING in Animal Facilities - Felasa

CAGE PROCESSING in Animal Facilities - Felasa

CAGE PROCESSING in Animal Facilities - Felasa

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

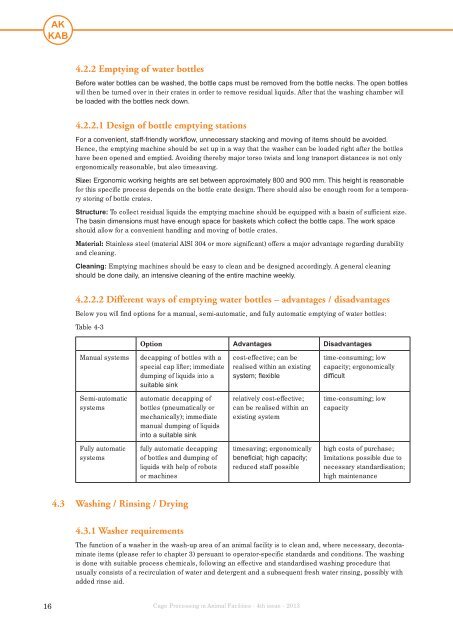

4.2.2 Empty<strong>in</strong>g of water bottlesBefore water bottles can be washed, the bottle caps must be removed from the bottle necks. The open bottleswill then be turned over <strong>in</strong> their crates <strong>in</strong> order to remove residual liquids. After that the wash<strong>in</strong>g chamber willbe loaded with the bottles neck down.4.2.2.1 Design of bottle empty<strong>in</strong>g stationsFor a convenient, staff-friendly workflow, unnecessary stack<strong>in</strong>g and mov<strong>in</strong>g of items should be avoided.Hence, the empty<strong>in</strong>g mach<strong>in</strong>e should be set up <strong>in</strong> a way that the washer can be loaded right after the bottleshave been opened and emptied. Avoid<strong>in</strong>g thereby major torso twists and long transport distances is not onlyergonomically reasonable, but also timesav<strong>in</strong>g.Size: Ergonomic work<strong>in</strong>g heights are set between approximately 800 and 900 mm. This height is reasonablefor this specific process depends on the bottle crate design. There should also be enough room for a temporarystor<strong>in</strong>g of bottle crates.Structure: To collect residual liquids the empty<strong>in</strong>g mach<strong>in</strong>e should be equipped with a bas<strong>in</strong> of sufficient size.The bas<strong>in</strong> dimensions must have enough space for baskets which collect the bottle caps. The work spaceshould allow for a convenient handl<strong>in</strong>g and mov<strong>in</strong>g of bottle crates.Material: Sta<strong>in</strong>less steel (material AISI 304 or more significant) offers a major advantage regard<strong>in</strong>g durabilityand clean<strong>in</strong>g.Clean<strong>in</strong>g: Empty<strong>in</strong>g mach<strong>in</strong>es should be easy to clean and be designed accord<strong>in</strong>gly. A general clean<strong>in</strong>gshould be done daily, an <strong>in</strong>tensive clean<strong>in</strong>g of the entire mach<strong>in</strong>e weekly.4.2.2.2 Different ways of empty<strong>in</strong>g water bottles – advantages / disadvantagesBelow you will f<strong>in</strong>d options for a manual, semi-automatic, and fully automatic empty<strong>in</strong>g of water bottles:Table 4-3Option Advantages DisadvantagesManual systemsdecapp<strong>in</strong>g of bottles with aspecial cap lifter; immediatedump<strong>in</strong>g of liquids <strong>in</strong>to asuitable s<strong>in</strong>kcost-effective; can berealised with<strong>in</strong> an exist<strong>in</strong>gsystem; flexibletime-consum<strong>in</strong>g; lowcapacity; ergonomicallydifficultSemi-automaticsystemsautomatic decapp<strong>in</strong>g ofbottles (pneumatically ormechanically); immediatemanual dump<strong>in</strong>g of liquids<strong>in</strong>to a suitable s<strong>in</strong>krelatively cost-effective;can be realised with<strong>in</strong> anexist<strong>in</strong>g systemtime-consum<strong>in</strong>g; lowcapacityFully automaticsystemsfully automatic decapp<strong>in</strong>gof bottles and dump<strong>in</strong>g ofliquids with help of robotsor mach<strong>in</strong>estimesav<strong>in</strong>g; ergonomicallybeneficial; high capacity;reduced staff possiblehigh costs of purchase;limitations possible due tonecessary standardisation;high ma<strong>in</strong>tenance4.3 Wash<strong>in</strong>g / R<strong>in</strong>s<strong>in</strong>g / Dry<strong>in</strong>g4.3.1 Washer requirementsThe function of a washer <strong>in</strong> the wash-up area of an animal facility is to clean and, where necessary, decontam<strong>in</strong>ateitems (please refer to chapter 3) persuant to operator-specific standards and conditions. The wash<strong>in</strong>gis done with suitable process chemicals, follow<strong>in</strong>g an effective and standardised wash<strong>in</strong>g procedure thatusually consists of a recirculation of water and detergent and a subsequent fresh water r<strong>in</strong>s<strong>in</strong>g, possibly withadded r<strong>in</strong>se aid.16Cage Process<strong>in</strong>g <strong>in</strong> <strong>Animal</strong> <strong>Facilities</strong> · 4th issue · 2013