CAGE PROCESSING in Animal Facilities - Felasa

CAGE PROCESSING in Animal Facilities - Felasa

CAGE PROCESSING in Animal Facilities - Felasa

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

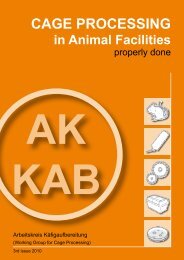

7.1.4 Dry<strong>in</strong>gDry<strong>in</strong>g means the process of remov<strong>in</strong>g water off items <strong>in</strong>side and outside a washer to a degree required for furtherprocess<strong>in</strong>g or <strong>in</strong>tended item use (tolerable residual moisture). The operator must determ<strong>in</strong>e, on <strong>in</strong>dividual conditionsand circumstances, the required degree of dry<strong>in</strong>g or if a dry<strong>in</strong>g is at all required before issu<strong>in</strong>g a tender.7.2 Test procedures for wash<strong>in</strong>g and decontam<strong>in</strong>ation of cages, racks,and wire lidsWash<strong>in</strong>g and decontam<strong>in</strong>ation tests require specially set up test strips. Although soil<strong>in</strong>g is primarily related toplastic surfaces, this material has low adhesive properties and may affect the properties of the test soil<strong>in</strong>g, forthis procedure we have selected strips made of sta<strong>in</strong>less steel, not plastic. Sta<strong>in</strong>less steel pieces are alreadyproven for the test for commercial dishwashers (DIN 10510, DIN 10512) and bed frame and cart decontam<strong>in</strong>ationsystems (AK-BWA Broschüre – AK-BWA brochure; series of standards DIN 58955) <strong>in</strong> the medical sector.Please f<strong>in</strong>d below a description of the setup of test strips, followed by a description of test procedures.7.2.1 Setup of test strips and test parametersA test strip must be fixed approximately 5 mm from the surface of the item to be processed. This setup allowsfor a complete wash<strong>in</strong>g around the test strip, reach<strong>in</strong>g also the non-contam<strong>in</strong>ated rear side, and avoids evaluationmistakes result<strong>in</strong>g from gaps between test strip and real item. The use of sta<strong>in</strong>less steel bolts and spacernuts is recommended. The contam<strong>in</strong>ated part of the test strip must face the same direction as the item surfaceto be washed.Fig. 7-1 Example test cage7.2.1.1 Cage bases7.2.1.1.1 Number of test strips per cage base5 test strips per cage baseFig. 7-2 Position of test strips on cage body48Cage Process<strong>in</strong>g <strong>in</strong> <strong>Animal</strong> <strong>Facilities</strong> · 4th issue · 2013