Managing Risks of Supply-Chain Disruptions: Dual ... - CiteSeerX

Managing Risks of Supply-Chain Disruptions: Dual ... - CiteSeerX

Managing Risks of Supply-Chain Disruptions: Dual ... - CiteSeerX

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

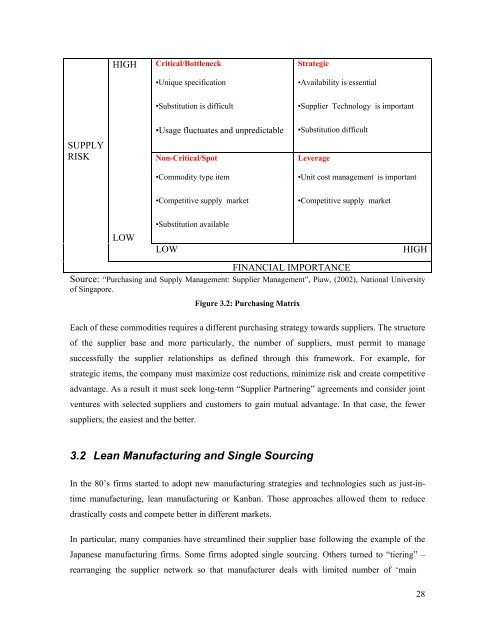

HIGHCritical/Bottleneck•Unique specificationStrategic•Availability is essential•Substitution is difficult•Supplier Technology is importantSUPPLYRISK•Usage fluctuates and unpredictableNon-Critical/Spot•Commodity type item•Substitution difficultLeverage•Unit cost management is important•Competitive supply market•Competitive supply market•Substitution availableLOWLOWHIGHFINANCIAL IMPORTANCESource: “Purchasing and <strong>Supply</strong> Management: Supplier Management”, Piaw, (2002), National University<strong>of</strong> Singapore.Figure 3.2: Purchasing MatrixEach <strong>of</strong> these commodities requires a different purchasing strategy towards suppliers. The structure<strong>of</strong> the supplier base and more particularly, the number <strong>of</strong> suppliers, must permit to managesuccessfully the supplier relationships as defined through this framework. For example, forstrategic items, the company must maximize cost reductions, minimize risk and create competitiveadvantage. As a result it must seek long-term “Supplier Partnering” agreements and consider jointventures with selected suppliers and customers to gain mutual advantage. In that case, the fewersuppliers, the easiest and the better.3.2 Lean Manufacturing and Single SourcingIn the 80’s firms started to adopt new manufacturing strategies and technologies such as just-intimemanufacturing, lean manufacturing or Kanban. Those approaches allowed them to reducedrastically costs and compete better in different markets.In particular, many companies have streamlined their supplier base following the example <strong>of</strong> theJapanese manufacturing firms. Some firms adopted single sourcing. Others turned to “tiering” –rearranging the supplier network so that manufacturer deals with limited number <strong>of</strong> ‘main28