ODU MAC

ODU MAC

ODU MAC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

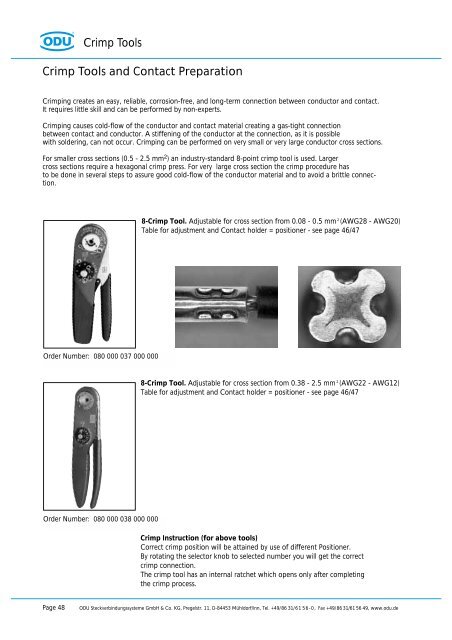

Crimp ToolsCrimp Tools and Contact PreparationCrimping creates an easy, reliable, corrosion-free, and long-term connection between conductor and contact.It requires little skill and can be performed by non-experts.Crimping causes cold-flow of the conductor and contact material creating a gas-tight connectionbetween contact and conductor. A stiffening of the conductor at the connection, as it is possiblewith soldering, can not occur. Crimping can be performed on very small or very large conductor cross sections.For smaller cross sections (0.5 - 2.5 mm 2 ) an industry-standard 8-point crimp tool is used. Largercross sections require a hexagonal crimp press. For very large cross section the crimp procedure hasto be done in several steps to assure good cold-flow of the conductor material and to avoid a brittle connection.8-Crimp Tool. Adjustable for cross section from 0.08 - 0.5 mm 2 (AWG28 - AWG20)Table for adjustment and Contact holder = positioner - see page 46/47Order Number: 080 000 037 000 0008-Crimp Tool. Adjustable for cross section from 0.38 - 2.5 mm 2 (AWG22 - AWG12)Table for adjustment and Contact holder = positioner - see page 46/47Order Number: 080 000 038 000 000Crimp Instruction (for above tools)Correct crimp position will be attained by use of different Positioner.By rotating the selector knob to selected number you will get the correctcrimp connection.The crimp tool has an internal ratchet which opens only after completingthe crimp process.Page 48<strong>ODU</strong> Steckverbindungssysteme GmbH & Co. KG, Pregelstr. 11, D-84453 Mühldorf/Inn, Tel. +49/86 31/61 56-0, Fax +49/86 31/61 56 49, www.odu.de