Download full report - Toyota Motor Europe

Download full report - Toyota Motor Europe

Download full report - Toyota Motor Europe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Environmental impact of facilities<br />

All 14 of our parts distribution centres are certified to the<br />

ISO14001 Environmental Management System. The key<br />

environmental aspects we track are energy consumption<br />

and waste management.<br />

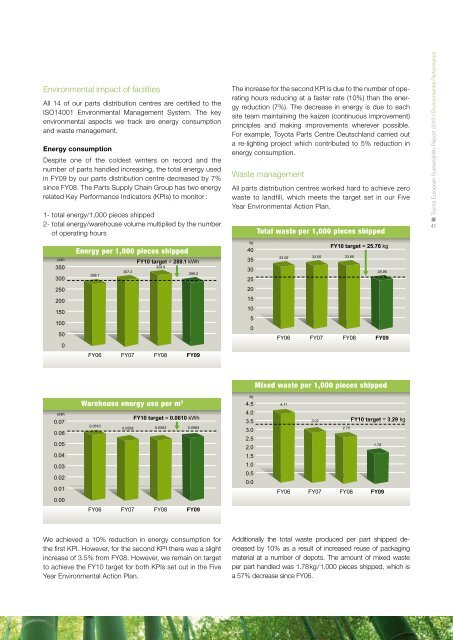

Energy consumption<br />

Despite one of the coldest winters on record and the<br />

number of parts handled increasing, the total energy used<br />

in FY09 by our parts distribution centre decreased by 7%<br />

since FY08. The Parts Supply Chain Group has two energy<br />

related Key Performance Indicators (KPIs) to monitor :<br />

1- total energy/1,000 pieces shipped<br />

2- total energy/warehouse volume multiplied by the number<br />

of operating hours<br />

kWh<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

kWh<br />

0.07<br />

0.06<br />

0.05<br />

0.04<br />

0.03<br />

0.02<br />

0.01<br />

0.00<br />

Energy per 1,000 pieces shipped<br />

288.1<br />

307.2<br />

FY10 target = 288.1 kWh<br />

329.9<br />

296.0<br />

FY06 FY07 FY08 FY09<br />

Warehouse energy use per m 3<br />

0.0610<br />

FY10 target = 0.0610 kWh<br />

0.0558 0.0563 0.0584<br />

FY06 FY07 FY08 FY09<br />

We achieved a 10% reduction in energy consumption for<br />

the first KPI. However, for the second KPI there was a slight<br />

increase of 3.5% from FY08. However, we remain on target<br />

to achieve the FY10 target for both KPIs set out in the Five<br />

Year Environmental Action Plan.<br />

The increase for the second KPI is due to the number of operating<br />

hours reducing at a faster rate (10%) than the energy<br />

reduction (7%). The decrease in energy is due to each<br />

site team maintaining the kaizen (continuous improvement)<br />

principles and making improvements wherever possible.<br />

For example, <strong>Toyota</strong> Parts Centre Deutschland carried out<br />

a re-lighting project which contributed to 5% reduction in<br />

energy consumption.<br />

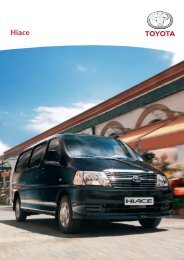

Waste management<br />

All parts distribution centres worked hard to achieve zero<br />

waste to landfill, which meets the target set in our Five<br />

Year Environmental Action Plan.<br />

kg<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

kg<br />

4.5<br />

4.0<br />

3.5<br />

3.0<br />

2.5<br />

2.0<br />

1.5<br />

1.0<br />

0.5<br />

0.0<br />

Total waste per 1,000 pieces shipped<br />

33.09 33.55 33.65<br />

FY10 target = 25.76 kg<br />

25.96<br />

FY06 FY07 FY08 FY09<br />

Mixed waste per 1,000 pieces shipped<br />

4.11<br />

3.02<br />

FY06 FY07 FY08 FY09<br />

Additionally the total waste produced per part shipped decreased<br />

by 10% as a result of increased reuse of packaging<br />

material at a number of depots. The amount of mixed waste<br />

per part handled was 1.78 kg / 1,000 pieces shipped, which is<br />

a 57% decrease since FY06.<br />

2.75<br />

FY10 target = 3.29 kg<br />

1.78<br />

<strong>Toyota</strong> <strong>Europe</strong>an Sustainability Report 2010 I Environmental Performance<br />

41