Download full report - Toyota Motor Europe

Download full report - Toyota Motor Europe

Download full report - Toyota Motor Europe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Health and Safety<br />

Having a strong foundation for safety is fundamental in<br />

a changing environment. Changes in FY09, including<br />

preparation for manufacturing hybrid vehicles in <strong>Europe</strong>,<br />

meant we faced many new challenges. This process has<br />

given us an opportunity to expand our knowledge and further<br />

strengthen our safety culture.<br />

This effort has already been recognised, with <strong>Toyota</strong> <strong>Motor</strong><br />

Manufacturing Poland (TMMP) winning a national award for<br />

safety in the workplace – “ Pracodawca – Organizator pracy<br />

bezpiecznej ” (Safe Work Organiser) in 2009. More than 400<br />

organisations competed to win this award.<br />

In FY10, we will continue to strengthen safety communication<br />

with the creation of a ‘Safety Promotion Committee,’ made<br />

up of representatives from senior management, who will set<br />

the direction on safety throughout our <strong>Europe</strong>an operations.<br />

In parallel, the process of sharing safety information and<br />

best practice between different areas of our business will be<br />

strengthened, so that our safety management system will<br />

continue to develop.<br />

Production and health and safety employees at TMMP with the<br />

Safe Work Organiser award<br />

Safety in our parts centres<br />

Our 14 parts distribution centres are responsible for the storage<br />

and distribution of parts and accessories to retailers around <strong>Europe</strong>.<br />

Following the introduction of a global strategy (called “ STOP<br />

6 ”) in FY08 which aims to reduce the risk of the most<br />

serious and frequently occurring types of accidents within<br />

our operations, a significant improvement was made. This<br />

improvement has continued through FY09.<br />

STOP 6 risk assessment tools and check sheets were<br />

developed and are now used at each depot. As a result<br />

of these assessments, we implemented a number of<br />

improvements and the level of risk has significantly reduced.<br />

As part of its STOP 6 activity, <strong>Toyota</strong>’s <strong>Europe</strong>an distribution<br />

centre - <strong>Toyota</strong> Parts Centre <strong>Europe</strong> (TPCE), focused on<br />

separating human work and machine work, avoiding falls<br />

from height and developing a safety awareness plan.<br />

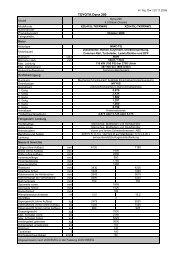

Freq rate<br />

%<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Formula: No of LTI/ Work hours x 1,000,000<br />

Note : TPCE included<br />

Lost Time Injury frequency rate<br />

in Parts Centres and TPCE<br />

35.29<br />

FY07 FY08 FY09<br />

13 Parts Centres only<br />

28.56<br />

27.77<br />

Safety in vehicle logistics<br />

We take an active role in ensuring the safety of our contracted<br />

vehicle logistics network. In FY09, for example, we worked<br />

with our rail logistics partners to prevent falls from height<br />

during rail transport.<br />

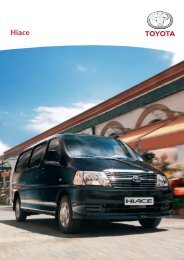

Pedestrian access to the top of the rail carriages used to<br />

transport our cars is essential. Due to the height of rail bridges,<br />

it is not possible to install a fixed barrier which would protect<br />

employees from falling from the top of the rail carriage. Our<br />

vehicle logistics team worked with our rail logistics partners<br />

to overcome this challenge. The group developed a system<br />

of adjustable barriers, which protects employees from falling<br />

while ensuring that the carriages remain suitable for rail<br />

travel throughout the <strong>Europe</strong>an network.<br />

Adjustable barriers fixed to rail carriages<br />

<strong>Toyota</strong> <strong>Europe</strong>an Sustainability Report 2010 I Social Performance<br />

73