Onix Installation Manual.qxd - Affordable Home Inspections

Onix Installation Manual.qxd - Affordable Home Inspections

Onix Installation Manual.qxd - Affordable Home Inspections

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

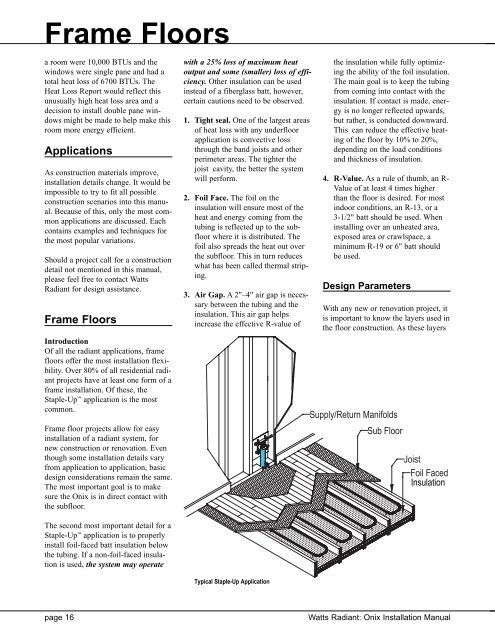

Frame Floorsa room were 10,000 BTUs and thewindows were single pane and had atotal heat loss of 6700 BTUs. TheHeat Loss Report would reflect thisunusually high heat loss area and adecision to install double pane windowsmight be made to help make thisroom more energy efficient.ApplicationsAs construction materials improve,installation details change. It would beimpossible to try to fit all possibleconstruction scenarios into this manual.Because of this, only the most commonapplications are discussed. Eachcontains examples and techniques forthe most popular variations.Should a project call for a constructiondetail not mentioned in this manual,please feel free to contact WattsRadiant for design assistance.Frame FloorsIntroductionOf all the radiant applications, framefloors offer the most installation flexibility.Over 80% of all residential radiantprojects have at least one form of aframe installation. Of these, theStaple-Up application is the mostcommon.Frame floor projects allow for easyinstallation of a radiant system, fornew construction or renovation. Eventhough some installation details varyfrom application to application, basicdesign considerations remain the same.The most important goal is to makesure the <strong>Onix</strong> is in direct contact withthe subfloor.The second most important detail for aStaple-Up application is to properlyinstall foil-faced batt insulation belowthe tubing. If a non-foil-faced insulationis used, the system may operatewith a 25% loss of maximum heatoutput and some (smaller) loss of efficiency.Other insulation can be usedinstead of a fiberglass batt, however,certain cautions need to be observed.1. Tight seal. One of the largest areasof heat loss with any underfloorapplication is convective lossthrough the band joists and otherperimeter areas. The tighter thejoist cavity, the better the systemwill perform.2. Foil Face. The foil on theinsulation will ensure most of theheat and energy coming from thetubing is reflected up to the subfloorwhere it is distributed. Thefoil also spreads the heat out overthe subfloor. This in turn reduceswhat has been called thermal striping.3. Air Gap. A 2"–4" air gap is necessarybetween the tubing and theinsulation. This air gap helpsincrease the effective R-value ofTypical Staple-Up Applicationthe insulation while fully optimizingthe ability of the foil insulation.The main goal is to keep the tubingfrom coming into contact with theinsulation. If contact is made, energyis no longer reflected upwards,but rather, is conducted downward.This can reduce the effective heatingof the floor by 10% to 20%,depending on the load conditionsand thickness of insulation.4. R-Value. As a rule of thumb, an R-Value of at least 4 times higherthan the floor is desired. For mostindoor conditions, an R-13, or a3-1/2" batt should be used. Wheninstalling over an unheated area,exposed area or crawlspace, aminimum R-19 or 6" batt shouldbe used.Design ParametersWith any new or renovation project, itis important to know the layers used inthe floor construction. As these layersSupply/Return ManifoldsSub FloorJoistFoil FacedInsulationpage 16Watts Radiant: <strong>Onix</strong> <strong>Installation</strong> <strong>Manual</strong>