Onix Installation Manual.qxd - Affordable Home Inspections

Onix Installation Manual.qxd - Affordable Home Inspections

Onix Installation Manual.qxd - Affordable Home Inspections

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

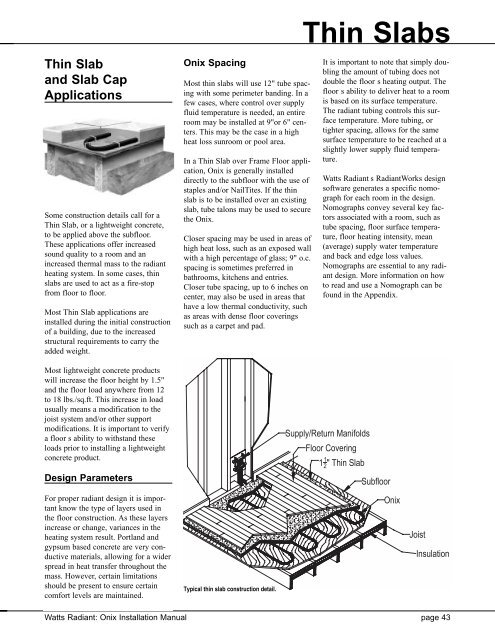

Thin SlabsThin Slaband Slab CapApplicationsSome construction details call for aThin Slab, or a lightweight concrete,to be applied above the subfloor.These applications offer increasedsound quality to a room and anincreased thermal mass to the radiantheating system. In some cases, thinslabs are used to act as a fire-stopfrom floor to floor.Most Thin Slab applications areinstalled during the initial constructionof a building, due to the increasedstructural requirements to carry theadded weight.<strong>Onix</strong> SpacingMost thin slabs will use 12" tube spacingwith some perimeter banding. In afew cases, where control over supplyfluid temperature is needed, an entireroom may be installed at 9"or 6" centers.This may be the case in a highheat loss sunroom or pool area.In a Thin Slab over Frame Floor application,<strong>Onix</strong> is generally installeddirectly to the subfloor with the use ofstaples and/or NailTites. If the thinslab is to be installed over an existingslab, tube talons may be used to securethe <strong>Onix</strong>.Closer spacing may be used in areas ofhigh heat loss, such as an exposed wallwith a high percentage of glass; 9" o.c.spacing is sometimes preferred inbathrooms, kitchens and entries.Closer tube spacing, up to 6 inches oncenter, may also be used in areas thathave a low thermal conductivity, suchas areas with dense floor coveringssuch as a carpet and pad.It is important to note that simply doublingthe amount of tubing does notdouble the floor s heating output. Thefloor s ability to deliver heat to a roomis based on its surface temperature.The radiant tubing controls this surfacetemperature. More tubing, ortighter spacing, allows for the samesurface temperature to be reached at aslightly lower supply fluid temperature.Watts Radiant s RadiantWorks designsoftware generates a specific nomographfor each room in the design.Nomographs convey several key factorsassociated with a room, such astube spacing, floor surface temperature,floor heating intensity, mean(average) supply water temperatureand back and edge loss values.Nomographs are essential to any radiantdesign. More information on howto read and use a Nomograph can befound in the Appendix.Most lightweight concrete productswill increase the floor height by 1.5"and the floor load anywhere from 12to 18 lbs./sq.ft. This increase in loadusually means a modification to thejoist system and/or other supportmodifications. It is important to verifya floor s ability to withstand theseloads prior to installing a lightweightconcrete product.Supply/Return ManifoldsFloor Covering12" 1 Thin SlabDesign ParametersSubfloorFor proper radiant design it is importantknow the type of layers used inthe floor construction. As these layersincrease or change, variances in theheating system result. Portland andgypsum based concrete are very conductivematerials, allowing for a widerspread in heat transfer throughout themass. However, certain limitationsshould be present to ensure certaincomfort levels are maintained.Typical thin slab construction detail.<strong>Onix</strong>JoistInsulationWatts Radiant: <strong>Onix</strong> <strong>Installation</strong> <strong>Manual</strong> page 43