Onix Installation Manual.qxd - Affordable Home Inspections

Onix Installation Manual.qxd - Affordable Home Inspections

Onix Installation Manual.qxd - Affordable Home Inspections

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

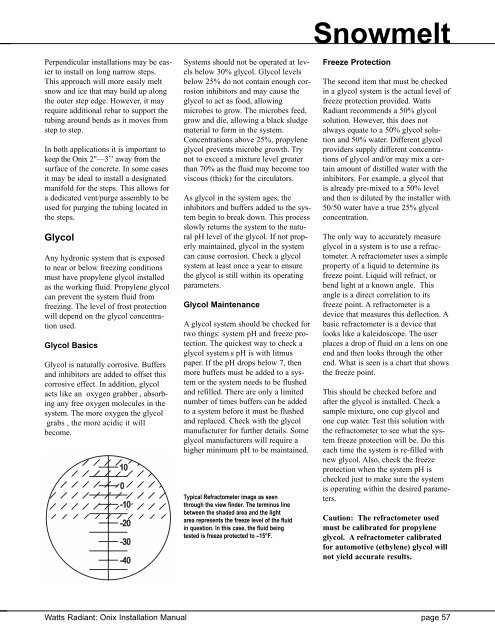

Perpendicular installations may be easierto install on long narrow steps.This approach will more easily meltsnow and ice that may build up alongthe outer step edge. However, it mayrequire additional rebar to support thetubing around bends as it moves fromstep to step.In both applications it is important tokeep the <strong>Onix</strong> 2"—3’’ away from thesurface of the concrete. In some casesit may be ideal to install a designatedmanifold for the steps. This allows fora dedicated vent/purge assembly to beused for purging the tubing located inthe steps.GlycolAny hydronic system that is exposedto near or below freezing conditionsmust have propylene glycol installedas the working fluid. Propylene glycolcan prevent the system fluid fromfreezing. The level of frost protectionwill depend on the glycol concentrationused.Glycol BasicsGlycol is naturally corrosive. Buffersand inhibitors are added to offset thiscorrosive effect. In addition, glycolacts like an oxygen grabber , absorbingany free oxygen molecules in thesystem. The more oxygen the glycolgrabs , the more acidic it willbecome.100-10-20-30-40Systems should not be operated at levelsbelow 30% glycol. Glycol levelsbelow 25% do not contain enough corrosioninhibitors and may cause theglycol to act as food, allowingmicrobes to grow. The microbes feed,grow and die, allowing a black sludgematerial to form in the system.Concentrations above 25%, propyleneglycol prevents microbe growth. Trynot to exceed a mixture level greaterthan 70% as the fluid may become tooviscous (thick) for the circulators.As glycol in the system ages, theinhibitors and buffers added to the systembegin to break down. This processslowly returns the system to the naturalpH level of the glycol. If not properlymaintained, glycol in the systemcan cause corrosion. Check a glycolsystem at least once a year to ensurethe glycol is still within its operatingparameters.Glycol MaintenanceA glycol system should be checked fortwo things: system pH and freeze protection.The quickest way to check aglycol system s pH is with litmuspaper. If the pH drops below 7, thenmore buffers must be added to a systemor the system needs to be flushedand refilled. There are only a limitednumber of times buffers can be addedto a system before it must be flushedand replaced. Check with the glycolmanufacturer for further details. Someglycol manufacturers will require ahigher minimum pH to be maintained.Typical Refractometer image as seenthrough the view finder. The terminus linebetween the shaded area and the lightarea represents the freeze level of the fluidin question. In this case, the fluid beingtested is freeze protected to –15°F.SnowmeltFreeze ProtectionThe second item that must be checkedin a glycol system is the actual level offreeze protection provided. WattsRadiant recommends a 50% glycolsolution. However, this does notalways equate to a 50% glycol solutionand 50% water. Different glycolproviders supply different concentrationsof glycol and/or may mix a certainamount of distilled water with theinhibitors. For example, a glycol thatis already pre-mixed to a 50% leveland then is diluted by the installer with50/50 water have a true 25% glycolconcentration.The only way to accurately measureglycol in a system is to use a refractometer.A refractometer uses a simpleproperty of a liquid to determine itsfreeze point. Liquid will refract, orbend light at a known angle. Thisangle is a direct correlation to itsfreeze point. A refractometer is adevice that measures this deflection. Abasic refractometer is a device thatlooks like a kaleidoscope. The userplaces a drop of fluid on a lens on oneend and then looks through the otherend. What is seen is a chart that showsthe freeze point.This should be checked before andafter the glycol is installed. Check asample mixture, one cup glycol andone cup water. Test this solution withthe refractometer to see what the systemfreeze protection will be. Do thiseach time the system is re-filled withnew glycol. Also, check the freezeprotection when the system pH ischecked just to make sure the systemis operating within the desired parameters.Caution: The refractometer usedmust be calibrated for propyleneglycol. A refractometer calibratedfor automotive (ethylene) glycol willnot yield accurate results.Watts Radiant: <strong>Onix</strong> <strong>Installation</strong> <strong>Manual</strong> page 57