BooTENDS TnRoITIoNAL SuurTERs STEp TooI Box ... - Wood Tools

BooTENDS TnRoITIoNAL SuurTERs STEp TooI Box ... - Wood Tools

BooTENDS TnRoITIoNAL SuurTERs STEp TooI Box ... - Wood Tools

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

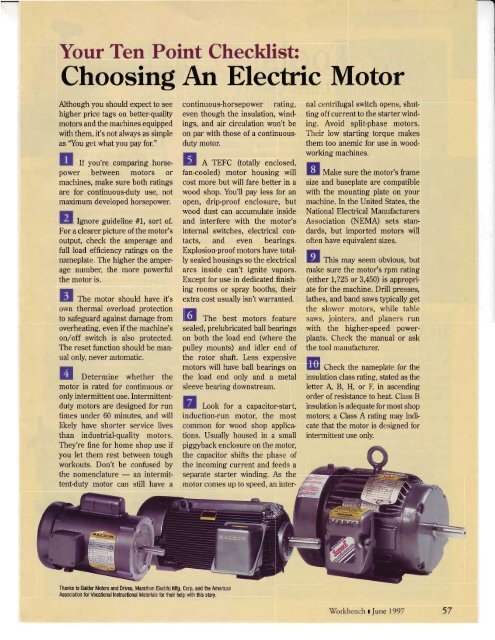

Your Ten Point Checklist:Choosing An Elecffic MotorAlthough you should expecto seehigher price tags on better-qualitymotors and the machines equippedwith them, it's not always as simpleas 'You get what you pay for."lI If you're comparing horsepowerbetween motors ormachines, make sure both ratingsare for continuous-duty use, notmaximum developed horsepower.Zl Ignore guideline #1, sort of.For a clearer picture of the motor'soutput, check the amperage andfull load efficiency ratings on thenameplate. The higher the amperagenumber, the more powerfulthe motor is.E *" motor should have it'sown thermal overload protectionto safeguard against damage fromoverheating, even if the machine'son/off. switch is also protected.The reset function should be manualonly, never automatic.A Determine whether themotor is rated for continuous oronly intermittent use. Intermittentdutymotors are designed for runtimes under 60 minutes, and willlikely have shorter service livesthan industrial-quality motors.They're fine for home shop use ifyou let them rest between toughworkouts. Don't be confused bythe nomenclature - an intermittent-dutymotor can still have acontinuous-horsepower rating,even though the insulation, windings,and air circulation won't beon par with those of a continuousdutymotor.E o rEFC (totally enclosed,fan-cooled) motor housing willcost more but will fare better in awood shop. You'll pay less for anopen, drip-proof enclosure, butwood dust can accumulate insideand interfere with the motor'sinternal switches, electrical contacts,and even bearings.Explosion-proof motors have totallysealed housings so the electricalarcs inside can't ignite vapors.Except for use in dedicated finishingrooms or spray booths, theirextra cost usually isn't warranted.The best motors featuresealed, prelubricated ball bearingson both the load end (where thepulley mounts) and idler end ofthe rotor shaft. Less expensivemotors will have ball bearings onthe load end only and a metalsleeve bearing downstream.look for a capacitor-start,induction-run motor, the mostcommon for wood shop applications.Usually housed in a smallpiggyback enclosure on the motor,the capacitor shifts the phase ofthe incoming current and feeds aseparate starter winding. As themotor comes up to speed, an internalcentrifugal switch opens, shuttingoff current to the starter winding.Avoid split-phase motors.Their low starting torque makesthem too anemic for use in woodworkingmachines.E t*" sure the motor's framesize and baseplate are compatiblewith the mounting plate on yourmachine. In the United States, theNational Electrical ManufacturersAssociation (NEMA) sets standards,but imported motors willoften have equivalent sizes.IZ This mav seem obvious. butmake sure the motor's rpm rating(either I,725 or 3,450) is appropriatefor the machine. Drill presses,lathes, and band saws typically getthe slower motors, while tablesaws, jointers, and planers runwith the higher-speed powerplants.Check the manual or askthe tool manufacturer.Illll Check the nameplate for theinsulation class rating, stated as theletter A, B, H, or [, in ascendingorder ofresistance to heal Class Binsulation is adequate for most shopmotors; a Class A rating may indi.cate that the motor is designed forintermittent use only.Thanks to Baldor Mobrs and Drfues, Marafion Electlc Mfg. Corp, and ttre AmerlcanAssoclaton for Vocatonal Insfucdonal Materlals for heh help wlh thls story.\Torkbench tJune 1997 57

![Til]tl](https://img.yumpu.com/45878240/1/190x245/tiltl.jpg?quality=85)