You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

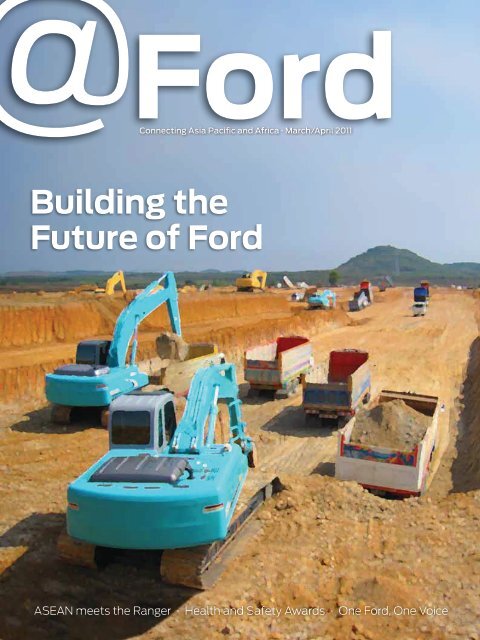

<strong>Ford</strong><br />

Connecting Asia Pacific and Africa · March/April 2011<br />

Building the<br />

Future of <strong>Ford</strong><br />

ASEAN meets the Ranger · Health and Safety Awards · One <strong>Ford</strong>, One Voice

Growing<br />

opportunities<br />

by Joe Hinrichs<br />

President, Asia Pacific and Africa<br />

<strong>Ford</strong> Motor Company<br />

Hi everyone,<br />

I was recently asked by a journalist what I thought about the potential<br />

slowdown in the Chinese and <strong>APA</strong> markets.<br />

“Slowdown?” I asked. The industry’s seasonally adjusted average rate<br />

(SAAR) may be lower in the first few months of 2011 than in 2010, but<br />

China remains the biggest and fastest growing market in the world,<br />

with 18 million vehicles sold in 2010.<br />

The Chinese market has “slowed” to 10 per cent growth this year.<br />

That’s 1.8 million vehicles. In manufacturing terms, that’s six new<br />

plants and about 25,000 people. If you include suppliers in the<br />

equation, with a 7:1 multiplier factor, we’re talking about 150,000 jobs.<br />

Every market in the world wants the kind of slowdown that brings<br />

150,000 additional jobs.<br />

One of the most challenging and important parts of being an original<br />

equipment manufacturer (OEM) is aligning capacity accurately with<br />

demand, and having the ability to adjust capacity quickly based on<br />

fluctuations in the market, or if we have a hot-selling product.<br />

This is not only important for our assembly plants, but for our entire<br />

supply chain as well.<br />

In this edition of @<strong>Ford</strong>, there is a story about the growing<br />

manufacturing footprint in <strong>APA</strong>. In order to bring 50 new vehicles and<br />

powertrains to <strong>APA</strong> by 2015, the footprint of <strong>Ford</strong> and our suppliers<br />

will continue to grow exponentially. As we grow, we have to do it<br />

strategically and wisely, installing enough capacity to give us flexibility<br />

to take advantage of opportunities, but not too much, which would be<br />

a burden on the system.<br />

Around 70 per cent of a vehicle is made by suppliers, so it is incredibly<br />

important that our supply chain – from the bigger Tier 1 suppliers,<br />

down to the smaller Tier 3 and 4 suppliers that support them – are in<br />

line with our capacity, and, importantly, meet our cost, quality,<br />

technology and delivery requirements.<br />

That’s why we gathered the top 100 global suppliers in Dearborn<br />

and gave them unprecedented access to the <strong>APA</strong> cycle plan and<br />

our mid-term growth strategy. Many of the Tier 1 suppliers have<br />

operations in <strong>APA</strong>, but not as many of their Tier 2 and Tier 3 suppliers<br />

do. We need a much leaner, more cost-effective, higher-quality supply<br />

chain that can help deliver the vehicles our customers want and value,<br />

for the right price and with great technology.<br />

As I’ve said, <strong>Ford</strong> has never attempted to grow as much as we are in<br />

the next few years throughout <strong>APA</strong>. These are exciting times. It’s going<br />

to be a challenging and fun ride and I’m glad we’re all in this together.<br />

Thank you for your hard work and dedication.<br />

One Team · One Plan · One Goal ·<br />

03 10<br />

04<br />

07<br />

03 Safety<br />

Teams from India and China<br />

win <strong>Ford</strong> President’s Health<br />

and Safety Awards<br />

04 Cover story<br />

Building the Future of <strong>Ford</strong><br />

07 Global watch<br />

How to make an engine roar<br />

08 Redesign<br />

Uncovering new Territory<br />

08 Mad Max<br />

Designing the ultimate<br />

Road Warrior<br />

10 Reveal<br />

The Ranger unveiled to ASEAN<br />

at the Bangkok International<br />

Motor Show<br />

@<strong>Ford</strong> March/April 2011<br />

12<br />

08<br />

contents<br />

12 One <strong>Ford</strong><br />

<strong>APA</strong> finds its singing voice<br />

14 Awards<br />

<strong>Ford</strong> New Zealand<br />

celebrates 20th annual<br />

Henry <strong>Ford</strong> Awards<br />

15 Variety Bash<br />

“Team True Blue” leads<br />

the 2011 Variety Bash<br />

16 News roundup<br />

A look at what’s happening<br />

throughout <strong>APA</strong><br />

18 <strong>Ford</strong> faces<br />

Talking to the trainers<br />

@<strong>Ford</strong> is published for the people of Asia Pacific and Africa, <strong>Ford</strong> Motor<br />

Company, by <strong>Ford</strong> Communications – 20th Floor, Lake Rajada Office<br />

Complex, 193/82-86 Ratchadapisek Road, Klongtoey, Bangkok, 10110,<br />

Thailand. Director/Publisher: Whitney Foard Small; Managing Editor:<br />

Mia Barrett; Editor: Gregor McClenaghan; Writers: PRISM Asia Pacific<br />

and Africa Content Factory; Design: Content Factory, Europe.<br />

A publication of <strong>Ford</strong> Communications Network. April 2011.<br />

Please send questions and comments on this issue to apamedia@ford.com

Safety First<br />

in <strong>APA</strong><br />

Three safety-conscious teams from <strong>APA</strong><br />

have been honoured at <strong>Ford</strong>’s 2010<br />

President’s Health and Safety Awards<br />

Contractors can only operate cranes once they have passed an internal<br />

<strong>Ford</strong> driving test, and are supervised by <strong>Ford</strong> staff at all times.<br />

Below: Body shop employees take a safety pledge at the start of every shift.<br />

safety<br />

The annual event recognises employees from around the<br />

world who have shown exceptional dedication to the health<br />

and safety ethos that <strong>Ford</strong> places at the heart of its<br />

operations.<br />

Two groups from India and one from China were winners in<br />

the Replication-Innovation category, which rewards teams<br />

that have developed ways of improving their health and<br />

safety operating systems and practices.<br />

The <strong>Ford</strong> India body shop won a Global Replication<br />

Innovation Award for its efforts to improve safety for the<br />

hundreds of new employees who joined the company as it<br />

prepared to build and launch the Figo.<br />

“We went from having around 450 people to more than<br />

1,150, and many of them had only just finished their technical<br />

training and were new to the industry,” said Ramesh Ganesan,<br />

senior engineer at the body shop.<br />

“We had some accidents – nothing serious, but if we did<br />

not take action there might have eventually been an injury, so<br />

we went back to look closely at the training people were<br />

receiving to see where we could improve.”<br />

The team developed training videos and other material,<br />

including knowledge tests, to help new employees visualise<br />

some of the dangers before they went on to the shop floor,<br />

and made sure these were available in the local language,<br />

Tamil. They paired trainees with experienced employees in a<br />

‘buddy’ system, and gave each employee a personal ‘Green<br />

Cross Card’ on which they update their safety performance<br />

every day.<br />

“A big part of the training was to get them to think of how<br />

important it is to their families that they are safe at work – we<br />

now have banners throughout the shop floor with slogans like<br />

‘My Safety is for Me and My Family’, and we take a safety<br />

pledge at the start of each shift. It was a cultural change for<br />

all of us, and everyone has embraced it – we are very proud<br />

and happy to receive the global award.”<br />

Also in India, the Lifting and Rigging process won a Regional<br />

Replication Innovation Award for reducing hazards in the<br />

plant connected to the use of cranes.<br />

“We found that some safety procedures were not being<br />

correctly followed by external contractors, so we introduced<br />

a permit system and an internal <strong>Ford</strong> driving licence to ensure<br />

that all crane drivers are properly trained; we also restricted<br />

the use of this equipment after sunset and have <strong>Ford</strong> supervisors<br />

working with contractors to make sure they follow<br />

procedure,” said safety engineer Bharath Kumar.<br />

In China, a team from the Jiangling Motors Corporation<br />

(JMC), a joint venture in Nanchang that assembles Transit<br />

vehicles, also won a Regional Replication Innovation Award<br />

for safety improvements to the repair and maintenance<br />

process on a production line.<br />

“We installed a camera inside the machine tool, so staff<br />

can check the status of the machine and collect data without<br />

having to turn the power off and go inside; this is safer and<br />

improves efficiency,” said Li Jun, deputy head of JMC’s<br />

security and technology department.<br />

“We care a lot about the safety of our staff and are honoured<br />

to win the award.”<br />

<strong>Ford</strong> Motor Company president and CEO Alan Mulally<br />

congratulated the winners for helping to keep their colleagues<br />

safe.<br />

“Ensuring the health and safety of our employees is critical<br />

as we continue working together to deliver our One <strong>Ford</strong><br />

plan; our entire team is so proud of these achievements,” he<br />

said.<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 3

cover story<br />

4 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

Building<br />

the Future<br />

of <strong>Ford</strong><br />

Brand new plants are under construction at Rayong in Thailand<br />

and Chongqing in China, while existing facilities in India, South<br />

Africa and elsewhere in the region have been massively expanded<br />

in recent years. With more projects in the pipeline, the <strong>APA</strong><br />

building boom shows no sign of slowing down.<br />

LOCATION, LOCATION, LOCATION<br />

A new plant is an investment running to hundreds of millions of<br />

dollars, and the choice of where to build it is a monumental<br />

decision that will have consequences for decades to come. Steve<br />

Day, the <strong>APA</strong> manufacturing director, has been involved in constructing<br />

some of the biggest auto plants in the region, and is one<br />

of the people who help narrow down where to build – from which<br />

part of the region, to which country, to which province or specific<br />

site within that country.<br />

“A lot depends on demand – we build where we sell, or where<br />

we can benefit from countries being part of something like the<br />

ASEAN Free Trade Area, or the free trade agreement between<br />

South Africa and the European Union,” he said.<br />

“We want to pick a market that has a good supply base, labour<br />

force, construction environment and infrastructure – we look at the<br />

factors that will help us deliver the best quality product at the best<br />

cost in that region.”<br />

He said the <strong>Ford</strong> Thailand Manufacturing (FTM) plant currently<br />

under construction in Rayong offered a good example of a site<br />

that ticked all the boxes in terms of location.<br />

The future of <strong>Ford</strong> is being<br />

built in Asia Pacific and Africa<br />

(<strong>APA</strong>), one brick at a time.<br />

Car sales in the region are<br />

expected to keep growing<br />

for years to come, and <strong>Ford</strong><br />

is rapidly expanding its <strong>APA</strong><br />

manufacturing operations<br />

to keep up with demand<br />

“Thailand’s a good hub, with good infrastructure, and we<br />

already have the joint venture AAT plant there; it also has free<br />

trade agreements with Australia and ASEAN, so it was an obvious<br />

location for that plant,” he said.<br />

“Once you’ve picked the country, you then have to go and find<br />

the best deal for land; sites suitable for a plant this size are<br />

actually few and far between, and you need somewhere with good<br />

logistics infrastructure, where it’s easy to have raw material<br />

coming in and finished goods going out, whether that’s to elsewhere<br />

in the country or for export abroad.”<br />

Another factor that can help narrow down the choice of where<br />

to site a new plant is whether national or local governments are<br />

able to offer investment incentives. New manufacturing sites can<br />

have an incredible economic impact on a region in terms of<br />

investment and jobs, especially automotive assembly plants,<br />

which bring other factories to feed the supply chain.<br />

“It varies hugely from country to country as well as between<br />

cities and states within a country – in Thailand, for example, there<br />

are national-level incentives available to companies investing in<br />

certain locations, but individual cities don’t really have the power<br />

to offer unique incentives or compete against one another, and the<br />

ability to negotiate special deals is limited,” said Gregory Daniels,<br />

director, <strong>APA</strong> tax.<br />

“At the other end of the spectrum is China, where many of the<br />

previous national incentives aimed at attracting foreign investment<br />

are being eliminated in a heavily debated attempt to level the

playing field between foreign and domestic<br />

firms. However, local governments have<br />

room to negotiate customised deals case by<br />

case. India is just about in the middle –<br />

there are some national policies but you can<br />

also negotiate across the different cities and<br />

states.”<br />

The types of incentives available include<br />

lump sum investment grants to help with<br />

construction costs, preferential land policies<br />

and locations, training grants, fixed term<br />

“tax holidays”, and other financial incentives<br />

tied to the level of government revenues<br />

generated as a result of the investment.<br />

“This latter form of incentive is growing in<br />

popularity with governments because it’s<br />

essentially revenue neutral on the margin<br />

– they’re not just handing over a cheque<br />

and hoping it creates jobs and revenue,”<br />

he said.<br />

“Typically the decision on where to build<br />

is driven by the manufacturing footprint, but<br />

investment incentives are clearly an important<br />

variable.”<br />

SAFETY FIRST<br />

Construction methods and skills might vary<br />

from country to country, but adhering to<br />

<strong>Ford</strong>’s strict safety standards is paramount<br />

on every project.<br />

“Local building codes and safety procedures<br />

do vary from place to place, but we<br />

have a very strict safety culture that we<br />

apply to all of our projects, wherever they<br />

are,” said Trevor Negus, manufacturing<br />

director for the <strong>Ford</strong> Thailand Manufacturing<br />

project.<br />

“The companies we have worked with on<br />

construction projects are global and highly<br />

professional businesses that understand the<br />

importance of ensuring that they and their<br />

sub-contractors are following <strong>Ford</strong>’s global<br />

safety procedures. They know that our<br />

expectation at <strong>Ford</strong> is not just to meet local<br />

standards but also our own, global safety<br />

standards, which often exceed what’s<br />

required locally, and they know how to<br />

achieve that with local contractors.”<br />

cover story<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 5

cover story<br />

ENERGY EFFICIENCY BUILT IN<br />

George Andraos is director of <strong>Ford</strong><br />

Land <strong>APA</strong>, the entity responsible<br />

for providing real estate services<br />

to <strong>Ford</strong> operations in the region.<br />

He said that the new plant in<br />

Thailand will be among the most<br />

energy efficient auto factories in<br />

the world.<br />

“The FTM plant is designed to<br />

make use of natural light, energy<br />

efficient lights and lighting controls,<br />

and a solar array will partially<br />

power the offices. One of our key<br />

global objectives is to develop an<br />

energy efficiency system that we<br />

can apply to everything we do. It<br />

6 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

offers a win-win outcome – it’s the<br />

right thing to do, the right thing<br />

for the environment, and the company<br />

saves a lot of money over<br />

the life cycle of the plant.”<br />

He said innovations developed<br />

in <strong>APA</strong> markets were setting the<br />

standards for <strong>Ford</strong>’s energy<br />

efficiency system world wide.<br />

“India in particular has been very<br />

proactive in this area, so this isn’t<br />

just something being imposed<br />

from the top – we are learning<br />

from what different places have<br />

tried and applying it elsewhere as<br />

we move towards a truly global<br />

organisation,” he said.<br />

Trevor Negus, manufacturing<br />

director for the FTM project,<br />

said that many environmentally<br />

friendly and energy efficient production<br />

line innovations, such as<br />

<strong>Ford</strong>’s "Three-Wet High-Solids”<br />

techno logy for painting vehicles,<br />

are also being built in to new<br />

plants.<br />

“There is less baking involved –<br />

we don’t have to bake each coat<br />

of paint before applying the next<br />

one, so obviously that uses less<br />

energy, and releases fewer compounds<br />

in to the atmosphere,<br />

while the use of high solids means<br />

there are fewer solvents in the<br />

paint,” he said.<br />

“Our consistent approach with all<br />

of our new plant projects is to<br />

implement all of our global best<br />

practice processes and facilities<br />

solutions. This will result in us<br />

delivering increasingly environmentally<br />

friendly and energy<br />

efficient plants.”<br />

MODULAR DESIGN<br />

A key requirement for a new plant is that it be able to easily switch to producing new<br />

models as they are introduced during its lifespan.<br />

“We construct the plant so it can produce any product in the stable – around 90 per<br />

cent of the production process is essentially the same for any vehicle,” said Day.<br />

“The goal is to have a generic bill of process that applies to any <strong>Ford</strong> plant anywhere<br />

in the world, so it is easy to change production. The robots we install are generic – it’s<br />

the software that is different from model X to model Y. It is like changing a drill bit – the<br />

drill itself doesn’t change, just that one small part, and for us the bill of process is the<br />

drill.”<br />

<strong>Ford</strong> plants are designed to build two or more different models on the same production<br />

line but with changeover stations, allowing the plant to continue producing even<br />

while introducing a new model.<br />

“If you design the bill of process right, you can install whatever changes you need for<br />

a new model offline and then integrate it without disrupting production,” said Day.<br />

During construction and before a new plant comes online, many months are also<br />

spent training the new workforce who will staff it.<br />

“If you don’t have a well trained workforce, you won’t succeed no matter how good<br />

the plant is,” said Day.<br />

“The goal is to deliver a 100 per cent quality product to the customer, and for that to<br />

happen, everything has to come together in the right place at the right time."

global watch<br />

ECOBOOST<br />

The Art<br />

of Noise<br />

<strong>Ford</strong>’s 1.6-litre EcoBoost<br />

is one of the most<br />

technologically advanced<br />

engines in production,<br />

combining high-pressure<br />

direct injection, a low-inertia<br />

turbo, and twin independent<br />

variable cam timing<br />

These three features give the EcoBoost the<br />

power and torque of a much larger engine<br />

without the size, weight and fuel economy penalties.<br />

There is, however, one slight downside to<br />

this technology.<br />

Turbocharging robs an engine of its natural<br />

voice, especially higher up the rev range. Floor<br />

the throttle in any turbocharged car and the<br />

whoosh of the turbo will overpower the driverpleasing<br />

induction, or charge, note.<br />

<strong>Ford</strong>’s engineers have overcome this aural<br />

obstacle in the new Focus by adding a small but<br />

hugely effective gadget called a sound symposer<br />

to the 1.6-litre EcoBoost engine. The symposer<br />

is a sound box that harvests good, engine-generated<br />

frequencies from the air intake system and<br />

sends them straight into the passenger<br />

compartment.<br />

The sound symposer helps<br />

give <strong>Ford</strong>'s 1.6-litre EcoBoost engine<br />

a sporty growl.<br />

“Our philosophy has<br />

always been that the<br />

car should sound refined<br />

at low and medium loads<br />

yet sporty and powerful<br />

at high loads.” Ralf Heinrichs<br />

<strong>Ford</strong> engineer Ralf Heinrichs explained: “All engines have their own sound character<br />

and it is the exhaust and/or intake system which determines this character. Typically,<br />

the exhaust system determines engine sound at low revs whereas higher up the rev<br />

range the intake system gives the engine its unique voice.<br />

“With turbocharged engines, the turbo is an integral part of the intake system and it<br />

masks the sound of induction because the whoosh noise becomes dominant when the<br />

turbo is spinning at speed.<br />

“We needed to recapture or recreate that exciting induction noise, so what we’ve done<br />

with our sound symposer is capture engine oscillations in the intake system downstream<br />

from the turbo and then direct them straight into the cabin for a good sporty growl.”<br />

The symposer has two chambers on the engine side and two on the outlet side,<br />

separated by a moveable flap. Under hard acceleration, the vibrations generated in the<br />

intake, or engine side, meet the pivoted flap, producing sound waves which are then<br />

transferred to the outlet chambers. These are transmitted into the passenger compartment<br />

via a sound pipe which runs through the bulkhead and into the car’s cabin.<br />

A big advantage with <strong>Ford</strong>’s sound symposer is that it doesn’t compromise refinement.<br />

In fact, engine noise is exceptionally quiet under most operating conditions.<br />

Heinrichs and his team use hyper-sensitive audio equipment to ensure the sound<br />

symposer works only when it should do and that the noises it delivers are rewarding<br />

without being overpowering.<br />

“Our philosophy has always been that the car should sound refined at low and<br />

medium loads yet sporty and powerful at high loads,” he said.<br />

“Engine noise should never become intrusive. Our sound symposer only contributes<br />

at high load and even at motorway speeds the engine noise is never intrusive. You can<br />

tune a sound symposer to produce all sorts of noises. How we tune ours is a very<br />

closely guarded secret!”<br />

This article originally appeared in the European edition of @<strong>Ford</strong>.<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 7

Australia<br />

8 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

Journalists crowd<br />

around the new<br />

Titanium model<br />

for their first look<br />

at the Territory<br />

redesign.<br />

Uncovering new Territory<br />

<strong>Ford</strong> Australia’s trademark SUV sports a new look<br />

Anticipation among Australia’s automotive<br />

media had been building for months,<br />

as motoring journalists waited to see the<br />

makeover <strong>Ford</strong> has given the new Territory.<br />

Their chance finally arrived on February 8,<br />

when <strong>Ford</strong> Australia President and CEO<br />

Bob Graziano literally tore the covers off the<br />

stunning new SUV at an invitation-only<br />

press event in Sydney.<br />

As Australia’s first locally designed and<br />

manufactured SUV, the Territory has a huge<br />

following. The unveiling at Sun Studios, in<br />

the heart of Sydney’s trendy fashion and<br />

photography district, felt like an exclusive<br />

coming-out party.<br />

The new Territory Titanium model sat<br />

beneath a gleaming array of spotlights.<br />

The vehicle was wrapped with a paper<br />

coating, covered with childlike sketches of<br />

the redesigned SUV’s exterior. It was similar<br />

to the wrapping used in a popular, long-running<br />

TV advertising campaign, where a boy<br />

covers up his family car with drawings to<br />

make it look more like a <strong>Ford</strong> Territory.<br />

Child actor Marko, the boy who starred in<br />

the ad, was there to help Graziano to tear<br />

off the sheathing and reveal a gleaming,<br />

never-before-seen Titanium.<br />

“Our new Territory has a new interior,<br />

a new exterior, new smart technologies<br />

and an all-new powertrain,” Graziano<br />

proudly announced.<br />

The <strong>Ford</strong> design team has completely<br />

revamped the SUV’s interior, refining the<br />

vehicle’s ergonomics and including plenty<br />

of useful storage space. High-tech features<br />

like a USB and audio jack make it easy<br />

for passengers to connect their mobile<br />

phones or an iPod. Smooth and sleek<br />

exterior lines give the Territory a more<br />

aerodynamic stance.<br />

Paul Gover and Paul Pottinger, writing<br />

for the Herald Sun, said the makeover<br />

gives the new Territory “a decidedly more<br />

premium feel.”<br />

After the formal unveiling, <strong>Ford</strong> Australia<br />

Vice President for Marketing, Sales and<br />

Service Beth Donovan joined Graziano for<br />

group interviews with the journalists,<br />

who were eager to learn more about the<br />

next-generation Territory. Exterior Design<br />

Manager Todd Willing and Interior Design<br />

Manager Scott Ferrier offered a detailed<br />

presentation about the kinetic design<br />

features of Australia’s trademark SUV.<br />

Emily Lai, <strong>Ford</strong> Australia’s colour and<br />

materials design manager was also on<br />

hand to answer questions from the press.<br />

President and CEO Bob Graziano poses<br />

with the Territory TS.<br />

The new Territory, shrouded in secrecy<br />

before its official unveiling to the press.<br />

The grille “presents a more dynamic face<br />

that will certainly turn heads,” observed<br />

Stephen Williams in the Weekend West<br />

Motoring section. “<strong>Ford</strong>'s keenness to<br />

take the new model up a notch in prestige<br />

feel is reflected in the addition of a big<br />

colour information screen and new cuttingedge<br />

fabrics.”<br />

Williams also praised the “curvaceous”<br />

Y-shape of the new, unified dash and<br />

centre console. He concluded that <strong>Ford</strong><br />

Australia has produced “the perfect family<br />

package many Territory fans have been<br />

waiting for without breaking their banks.”<br />

The Territory’s design debut was the<br />

first in a series of reveal events before the<br />

new SUV hits showrooms next month.<br />

Mechanical and technical details were<br />

shared with selected media on March 9.<br />

And in early April, automotive journalists<br />

from Australia and New Zealand got their<br />

first chance to drive the new <strong>Ford</strong> Territory,<br />

which will be available for the first time<br />

with a diesel engine.

Australia<br />

Return of Mad Max<br />

<strong>Ford</strong> joins forces with TopGear Australia to create the ultimate Road Warrior<br />

When Australian filmmaker George Miller<br />

announced that a fourth incarnation of<br />

the Mad Max movie series was in the<br />

works, the Aussie editors at TopGear began<br />

to wonder: will there be a new Interceptor?<br />

The gritty muscle car that Max used to<br />

patrol the post-apocalyptic Outback was<br />

blown to bits in Mad Max 2: The Road<br />

Warrior – until its demise the Interceptor had<br />

been the most reliable weapon in Mel<br />

Gibson’s crime fighting arsenal.<br />

In the 1970s, when Mad Max was conceived,<br />

<strong>Ford</strong> Australia designer Peter<br />

Arcadipane helped Miller to transform the<br />

XB GT Falcon coupe into the fearsome<br />

Interceptor. TopGear knew of this link to<br />

<strong>Ford</strong>, and their Mad Max cravings began to<br />

dovetail with their desire for another story<br />

they’d been craving: namely, a series of<br />

articles that would show readers how a<br />

major automaker’s design team goes about<br />

developing, defining and refining a concept<br />

car’s new look.<br />

Stephen Corby, TopGear Australia editor,<br />

approached <strong>Ford</strong> with a pie-in-the-sky<br />

proposal: would the <strong>Ford</strong> Australia Design<br />

Studio like to dream up a next-generation<br />

Interceptor? The entire process, from<br />

rough sketches to clay modeling would be<br />

chronicled in the pages of TopGear. To<br />

Corby’s astonishment, the answer was yes,<br />

and a very special project was born, giving<br />

unprecedented exposure to <strong>Ford</strong> Australia’s<br />

design team.<br />

“We asked, if the movie was made in<br />

2011, what would Mad Max drive today? We<br />

took an FG Falcon as our starting point,<br />

with no limits,” said Todd Willing, chief<br />

designer of passenger cars for <strong>Ford</strong> Asia<br />

Pacific and Africa. “This was a chance for<br />

the designers to really let their hair down,<br />

and for TopGear readers to see how<br />

a design grows from churning out a series<br />

of drawings on paper to becoming an<br />

actual vehicle.”<br />

Each member of the team produced a<br />

prototypical Mad Max concept car design.<br />

“We’ve been blown away by their application<br />

to the task, and the breadth and vision<br />

of the results,” Corby told @<strong>Ford</strong>. These<br />

initial drawings were featured in the<br />

February 2011 issue of TopGear Australia.<br />

With input from the editors, the design<br />

team chose Nima Nourian’s mean<br />

“Nimachine” and Simon Brook’s sinister<br />

“Brookliner” as the strongest concepts.<br />

These two designs were fleshed out a bit<br />

more, with suggestions from the entire <strong>Ford</strong><br />

Design Studio. Digital models were then<br />

created using Alias 3D software. These<br />

models are the centrepiece of a nine-page<br />

spread in the April 2011 issue, where<br />

TopGear asks readers to vote for their<br />

favourite on the magazine’s website,<br />

www.topgear.com. The Mad Max concept<br />

that wins the most online votes will go<br />

through a final stage of computer-assisted<br />

design, and come to life as a 40-percentlife-sized<br />

clay model that <strong>Ford</strong> is hoping to<br />

display at the upcoming Australian International<br />

Motor Show in Melbourne this July.<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 9

Ranger<br />

ASEAN Meets<br />

The Ranger<br />

The 32nd<br />

Bangkok International<br />

Motor Show saw hundreds<br />

of thousands of people stop by<br />

the <strong>Ford</strong> stand for the first glimpse<br />

of the all-new Ranger in ASEAN<br />

The truck, which will be manufactured in<br />

Thailand, South Africa and Argentina and<br />

go on sale later this year, was unveiled on<br />

the show’s media day by Joe Hinrichs,<br />

president of <strong>Ford</strong> Asia Pacific and Africa,<br />

who said it was “a great One <strong>Ford</strong> story”<br />

that showed the advantages of working as<br />

a global company.<br />

“Truck customers, from here in Thailand<br />

to Argentina, have very similar requirements<br />

from a compact truck – they are remarkably<br />

consistent, despite their geographic diversity.<br />

“What are those needs? Exceptional<br />

capabilities and versatility, durability, fuel<br />

efficiency, comfort and advanced<br />

technologies.”<br />

He said that with a customer segment<br />

so unified around the world, the possibilities<br />

to create a global product were endless.<br />

“With the One <strong>Ford</strong> business model, we<br />

have laid the foundation for creating one,<br />

world-class global platform that takes<br />

full advantage of global powertrains and<br />

technologies to transform the compact<br />

pickup driving experience.”<br />

10 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

INNOVATIVE DESIGN<br />

TO SUIT ANY NEED<br />

This was only the second time that the new<br />

Ranger has been seen in public since its<br />

grand unveiling in Sydney in October; before<br />

Bangkok it was shown to European truck<br />

fans at the Geneva Auto Show at the start of<br />

March. With each public appearance, more<br />

details of the truck have been revealed. In<br />

Geneva, the Wildtrak version, featuring<br />

sporty and aggressive colours and graphics,<br />

unique interior trim and other accessories,<br />

demonstrated that the Ranger is about style<br />

as well as utility; in Bangkok, visitors to the<br />

stand were able to see why the Ranger is the<br />

perfect vehicle for off road adventure.<br />

Driveline components like the oil pan are<br />

mounted above the frame rail where they<br />

are protected by strong cross-members<br />

when the truck is performing in rough<br />

terrain. To improve its water-wading capability,<br />

key electrical components and air<br />

inlets are strategically placed high in the<br />

engine compartment, allowing it to go<br />

deeper than other trucks; the 4x4 and 4x2<br />

Hi-Rider models can wade through 800 mm<br />

of water, a class-leading feature that will be<br />

welcomed by customers who need to ford<br />

rivers or floods.<br />

Customers will be able to choose from a<br />

range of cab styles and engines to suit their<br />

individual needs. As well as the double body<br />

style on show in Bangkok, the Ranger will<br />

also be available with a regular cab, or with<br />

a Rear Access Panels (RAP) cab, an innovative<br />

design from the last Ranger which has<br />

a unique four-door system allowing unobstructed<br />

access to the cabin through two<br />

forward-hinged doors and two rear-hinged<br />

access panels.<br />

More details of the three engines that<br />

Ranger customers will be able to choose<br />

from were also unveiled in Bangkok; a<br />

2.2-litre diesel, a 3.2-litre diesel, and a<br />

2.5-litre petrol engine that will deliver the<br />

best fuel economy in its class 1 .<br />

Visitors to the <strong>Ford</strong> stand were able to<br />

learn more about the Ranger’s features<br />

through interactive displays and activities,<br />

including a demonstration of the Bluetooth ®

The Ranger will be available with a double<br />

cabin (blue) and Rear Access Panels<br />

(silver), as well as a regular cab.<br />

<strong>Ford</strong> executives introduced the Ranger<br />

to ASEAN during the 32nd Bangkok<br />

International Motor Show.<br />

Voice Control system, and a simulator that<br />

allowed them to experience the 4x4 traction<br />

control, trailer sway control and off-road<br />

capabilities. A Robot Theatre taught visitors<br />

about <strong>Ford</strong>’s new range of powerful and fuel<br />

efficient engines, while a Driving Skills For<br />

Life simulator gave them the chance to<br />

improve their safe driving skills during a<br />

timed drive through a virtual town. There<br />

The Ranger can handle the toughest terrain.<br />

was also a slot-car challenge, which pitted<br />

members of the public against each other<br />

as they raced miniature versions of their<br />

favourite <strong>Ford</strong> cars.<br />

TRAINING THE TRAINERS<br />

Preparations are underway throughout <strong>APA</strong><br />

in advance of the Ranger’s highly anticipated<br />

launch. At the end of February, training<br />

managers from across the region gathered<br />

in Bangkok to discuss the needs and<br />

requirements of the training programmes<br />

that will educate <strong>Ford</strong> sales people about<br />

the new truck.<br />

“It was about listening to what the people<br />

responsible for training need. Each market<br />

has different challenges and requirements<br />

and we wanted to take that in to account<br />

very early on so we can tailor the training<br />

programmes and materials to meet those<br />

needs,” said Belinda Holland, from the <strong>Ford</strong><br />

Academy, who was one of those leading the<br />

session.<br />

“The all-new Ranger is our first global<br />

launch, and is such an important product in<br />

Ranger<br />

the region that we wanted the dealer<br />

network to be adequately prepared. We are<br />

focused on a holistic strategy across the life<br />

cycle of the Ranger, and the workshop was<br />

a great opportunity to sit with training<br />

managers and satisfy the needs of the<br />

various markets.”<br />

Peter Fleet, president of <strong>Ford</strong> ASEAN,<br />

said the new Ranger was generating a huge<br />

amount of interest, and that visitors to the<br />

Bangkok show were especially excited<br />

about the truck’s local pedigree.<br />

“This terrific new vehicle is the latest<br />

proof of how our One <strong>Ford</strong> strategy works,<br />

as it leveraged the full design and development<br />

resources within <strong>APA</strong> to create a<br />

world-class vehicle for our global operations,”<br />

he said.<br />

“Thailand already serves as a global<br />

manufacturing and exporting hub for <strong>Ford</strong><br />

Motor Company, and the decision to<br />

continue building our presence here highlights<br />

our continued confidence in the<br />

further development of Thailand’s already<br />

world-class automotive industry.”<br />

1 Officially approved tests in accordance with<br />

EC Directive 93/116/EC estimate the Ranger<br />

achieves 9.8 litres per 100 km in a combined<br />

drive cycle.<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 11

One <strong>Ford</strong><br />

One <strong>Ford</strong>,<br />

One Voice<br />

The sweet sound<br />

of success has<br />

been echoing<br />

around <strong>APA</strong> as<br />

<strong>Ford</strong>’s musical stars find<br />

a new way to work in harmony<br />

All over the region, talented employees have been singing from<br />

the same song sheet in mass musical meetings that have helped<br />

them connect with colleagues and feel good about working for <strong>Ford</strong>.<br />

The trend started in South Africa, where the employee reveal of the<br />

all-new Ranger last year brought workers together from sites thousands<br />

of kilometers apart.<br />

“We wanted to do something special that could make employees<br />

at both the Silverton plant in Pretoria and the Struandale plant in Port<br />

Elizabeth feel part of the same team and get them excited about the<br />

launch,” said Lloyd Marlowe, corporate communications manager for<br />

<strong>Ford</strong> Motor Company of Southern Africa (FMCSA).<br />

“We brought in a company called Fat Groove – they are a band<br />

from Pretoria, but they also do team building sessions for companies.<br />

They were excited by the challenge; the biggest group they had<br />

done before was about 50 or 60 people, but we wanted to get all<br />

2,600 employees at both our sites involved.”<br />

Different departments were asked to each submit a verse for the<br />

’One <strong>Ford</strong>’ song, with the best chosen by the musicians, who then<br />

composed an original tune.<br />

On the day of the reveal, a video link was set up between the two<br />

sites, with the Silverton plant singing the chorus and the Struandale<br />

plant providing the rhythm section by clapping and stamping their<br />

feet; each was recorded separately, but mixed together in just a few<br />

minutes so the entire song could be played back straight away. A CD<br />

12 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

was later distributed to all the employees as a Christmas present<br />

when they came back to work after the holidays.<br />

“It was out of this world – we had never experienced something<br />

like this in the history of FMCSA and it has lasted in the minds of our<br />

people,” said Sikhali Mathenjwa, mechanical supervisor at the<br />

Silverton plant.<br />

“The song is unique, with a little bit of pop and an R&B rhythm that<br />

makes you sing along every time it is played. It created a long lasting<br />

impression and gave confidence to all our team members to take this<br />

company forward.”<br />

“The day was good and gave us morale,” said Setumile Molaoa,<br />

team leader in the system two market area at Silverton.<br />

“The way they combined the song was amazing and the dancing<br />

and singing by the <strong>Ford</strong> choir was nice.”<br />

TAKING UP THE TUNE<br />

The song was so successful that it was used to introduce Alan<br />

Mulally, President and CEO of <strong>Ford</strong> Motor Company, when he drove<br />

a <strong>Ford</strong> Focus on to the stage at this year’s North American International<br />

Auto Show.<br />

As news of the event spread, <strong>Ford</strong> employees in Taiwan and then<br />

Shanghai recorded their own company songs, each with the theme<br />

of ‘One Team, One Plan, One Goal, One <strong>Ford</strong>.’

<strong>Ford</strong> <strong>APA</strong> President<br />

Joe Hinrichs was in fine<br />

voice during Chinese<br />

New Year celebrations<br />

in Shanghai.<br />

“In college I was a member of a Buddhist religious group and<br />

had experience organising singing events with big groups of<br />

people, so I was happy to be asked to get involved,” said John<br />

Tai, production superintendant at the body plant in Taiwan, who<br />

wrote the ‘<strong>Ford</strong> Heroes’ lyrics to the tune of one of his favourite<br />

pop songs from the early 1990s.<br />

“I was thinking about the theme of ‘One <strong>Ford</strong>’, and woke up<br />

with this song in my head; once I knew I wanted to use that tune,<br />

the lyrics came very quickly,” he said.<br />

“My version of the song is about having a dream in our hearts to<br />

improve <strong>Ford</strong> sales in Taiwan; competition is very tough and we<br />

need heroes from all over <strong>APA</strong> to help the company get better and<br />

better.”<br />

After working with colleagues to come up with a dance to<br />

accompany the song, John was one of around 260 employees<br />

drawn from all the divisions at <strong>Ford</strong> Lio Ho who practiced and then<br />

performed the song one night after the assembly line had shut<br />

down.<br />

“We were united together and danced together – everyone was<br />

very happy and felt good afterwards, with a lot of energy to reach<br />

our goals.”<br />

In Shanghai, a dozen senior managers including <strong>Ford</strong> <strong>APA</strong><br />

President Joe Hinrichs were joined on stage by some of 2010’s<br />

graduate trainees, at a party held just before the Chinese New<br />

Year. With a live band providing the music and around 420 employees<br />

from both the <strong>Ford</strong> China Operations and the regional<br />

<strong>APA</strong> offices joining in with the singing, the event was a harmonious<br />

way to see out the old year and welcome the new.<br />

“We had heard the songs from South Africa and Taiwan and<br />

thought they were amazing, and we wanted to continue the<br />

performance and sing the ‘One <strong>Ford</strong>’ idea to our team,” said<br />

human resources training specialist Tracy Huang, who wrote the<br />

lyrics for the Shanghai performance.<br />

“I think it was a great success; lots of people were involved in<br />

the performance, not just those who were on stage. It was a lot of<br />

fun and we are definitely thinking about doing it again.”<br />

One <strong>Ford</strong><br />

Employees in the Silverton and Struandale plants in South Africa were<br />

united in song over thousands of kilometers.<br />

<strong>Ford</strong> Lio Ho workers showed they were <strong>Ford</strong> Heroes<br />

with a co-ordinated song and dance.<br />

“One Team, One Plan, One Goal, One <strong>Ford</strong>.”<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 13

New Zealand<br />

The award winners pose for a group photo with the judges and representatives of <strong>Ford</strong> New Zealand.<br />

<strong>Ford</strong> New Zealand celebrates<br />

20th annual Henry <strong>Ford</strong> Awards<br />

The 2010<br />

Henry <strong>Ford</strong> Award winners<br />

Supreme Winner for Best<br />

Motoring Journalism of 2010<br />

David Linklater, “Auto Motives”,<br />

New Zealand Listener<br />

Best Published Photograph<br />

Cathy Parker, “Oops”, NZ4WD Magazine<br />

Best Environment Story<br />

Robert Barry, “Moving the goal posts?”,<br />

NZ Company Vehicle Magazine<br />

Best Safety Story<br />

Dave Moore “Drinking till the money runs out<br />

could be good for everyone”, NZ autocar<br />

Best Industry Story<br />

David Linklater, “Auto Motives”,<br />

New Zealand Listener<br />

Best Motorsport Story<br />

Shaun Summerfield, “Targa Rally” TV3<br />

Best Overall Product Story<br />

Dave Moore, “Room with a view”,<br />

Fairfax Newspapers<br />

Best <strong>Ford</strong> Product Story<br />

Dave Moore, “Frugal Fiesta”,<br />

Fairfax Newspapers<br />

Best Small Car Story<br />

Jacqui Madelin, “Zippy Mito with pedigree”,<br />

Herald on Sunday<br />

Best Technology Story<br />

Dave Moore, “Mazda’s Sky-high ambitions”,<br />

NZ autocar<br />

Best Story for Target<br />

Donn Anderson, “Lotus and the Cortina”,<br />

NZ Classic Car Magazine<br />

Special Award - Best <strong>Ford</strong> Falcon 50th<br />

Anniversary Story<br />

Damien O’Carroll, "Falcon’s 50th",<br />

Classic Driver Magazine<br />

14 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

<strong>Ford</strong> New Zealand hosted the country’s<br />

top motoring journalists in Auckland<br />

recently for the Henry <strong>Ford</strong> Awards at<br />

the Langham Hotel. The prestigious<br />

awards, now in their 20th year, recognise<br />

excellence in motoring journalism across a<br />

number of categories.<br />

“We are very fortunate in New Zealand<br />

to have so many talented, know-ledgable<br />

and passionate<br />

writers covering the<br />

industry and <strong>Ford</strong> is<br />

proud to be able to<br />

recognise that talent<br />

with the Henry <strong>Ford</strong><br />

Awards,” said<br />

Trevor Auger,<br />

Managing Director,<br />

<strong>Ford</strong> New Zealand.<br />

Returning judges<br />

Malcolm Teesdale<br />

and Perry Kerr<br />

joined <strong>Ford</strong> New<br />

Zealand Communications<br />

Manager<br />

Tom Clancy to<br />

select the winners this year. Teesdale has<br />

been involved in the motoring industry for<br />

a number of years; his late wife Louise<br />

was the originator of the media awards.<br />

Kerr is CEO of the Motor Industry Association<br />

of New Zealand and has also<br />

served as a Henry <strong>Ford</strong> judge for the past<br />

several years.<br />

“The great depth of writing skill in New<br />

Zealand makes the job difficult for our<br />

judges,” Auger added. “However, this<br />

depth of quality coverage is a real benefit<br />

to the industry, and more importantly,<br />

to consumers. Not only do we have<br />

compelling coverage of motorsport and<br />

other industry developments for those<br />

passionate about all things to do with<br />

cars, but with numerous in-depth reviews<br />

The New Zealand Listener’s David<br />

Linklater, winner of the Best Motoring<br />

Journalism 2010 award, with <strong>Ford</strong>'s Tom<br />

Clancy, Chris Masterson, second from left,<br />

and Trevor Auger, right.<br />

and new vehicle news, New Zealand<br />

consumers are able to make smart,<br />

informed choices.”<br />

Just before the awards dinner, <strong>Ford</strong><br />

New Zealand hosted the Annual <strong>Ford</strong><br />

Media Briefing, also at the Langham.<br />

Auger joined Chris Masterson, marketing<br />

director of <strong>Ford</strong> New Zealand, to present<br />

a group of journalists with a look back at<br />

significant corporate<br />

achievements of<br />

2010 and a look<br />

ahead at important<br />

upcoming events in<br />

2011.<br />

The briefing and<br />

awards dinner was<br />

a welcome break<br />

for three Christch<br />

urch-based journal-<br />

ists who managed<br />

to attend the<br />

function despite the<br />

devastating earthquake<br />

that struck<br />

the South Island just<br />

three days earlier. <strong>Ford</strong> New Zealand had<br />

considered postponing the events, but as<br />

it turned out the media appreciated a<br />

brief respite from the trauma and suffering<br />

the country has been experiencing in<br />

the aftermath of the quake.<br />

“I have been involved with the awards<br />

from their inception 20 years ago, and it<br />

is great that <strong>Ford</strong> continues to back this<br />

worthwhile annual recognition of local<br />

motoring writers,” said Donn Anderson<br />

from New Zealand Classic Car Magazine.<br />

Donn won a Henry <strong>Ford</strong> Award for<br />

“Lotus and the Cortina,” an article that<br />

chronicles the history of the beloved<br />

Lotus-Cortina, a high performance car<br />

born of a collaboration between <strong>Ford</strong><br />

and Lotus.

<strong>Ford</strong>’s 1963 Zephyr has become a Variety Bash icon.<br />

New Zealand<br />

“Team True Blue” motors along in the 2011 Variety Bash<br />

<strong>Ford</strong>-sponsored road trip raises money for needy children in Christchurch<br />

<strong>Ford</strong> New Zealand’s Team True Blue took<br />

part in yet another successful Variety<br />

Bash in March. This year, all the funds<br />

raised during the Bash will be going to help<br />

children affected by the earthquake in<br />

Christchurch.<br />

The 2011 Variety Bash consisted of a<br />

convoy of more than 25 old cars, fire<br />

engines and an assortment of odd and<br />

quirky vehicles. Taking turns behind the<br />

wheel of <strong>Ford</strong>’s mighty 1963 Zephyr pilot<br />

car was a team of <strong>Ford</strong> employees, <strong>Ford</strong><br />

dealers from around the country and motoring<br />

journalists.<br />

The Variety Bash is the core fundraising<br />

campaign for Variety, the Children’s Charity.<br />

The annual Bash is a raucous road trip full<br />

of unique vehicles, eccentric characters and<br />

heart-felt philanthropy. <strong>Ford</strong> plays a central<br />

part in the fun-filled caravan, which travels<br />

hundreds of kilometres every year through<br />

New Zealand raising funds, distributing<br />

grants and sharing Variety’s story of service.<br />

<strong>Ford</strong> New Zealand has sponsored Variety,<br />

the Children’s Charity since it was founded<br />

in 1989.<br />

<strong>Ford</strong>’s True Blue Bashers, as they are<br />

affectionately known, were on the road from<br />

March 5-12, travelling from the Bay of<br />

Plenty to the Bay of Islands. The 21st<br />

annual Variety Bash raised a total of<br />

NZD240,000 for sick, disabled and disadvantaged<br />

Kiwi kids. Along the way, the<br />

caravan handed out 25 grants worth more<br />

than NZD125,000 to help children in various<br />

schools and communities.<br />

“The Variety Bash was warmly greeted in<br />

every community we visited and we were<br />

particularly touched by school children<br />

raising money in whatever way they can to<br />

help other children with needs greater than<br />

their own. Helping Kiwi kids with grants<br />

during the Variety Bash would not be<br />

possible without the support of dedicated<br />

Bash sponsors like <strong>Ford</strong> New Zealand,”<br />

said Lorraine Taylor, CEO of Variety, the<br />

Children’s Charity.<br />

The Bashers contributed NZD59,000<br />

to the total through their combined efforts<br />

during the drive, and subsequent fundraising<br />

activities that included raffles, a<br />

TradeMe auction and a Bobby McFerrin<br />

concert co-sponsored by Cadbury.<br />

“People around New Zealand have been<br />

so generous in helping the people of<br />

Christchurch affected by the recent earth-<br />

Above: Crop to show smiling kids with<br />

balloons in center if you want to use this<br />

one. One of the many groups of school<br />

kids The Bash visited this year.<br />

The Variety bash<br />

caravan takes time out<br />

for a Fun Stop on the roadside.<br />

quake, by putting donations into the Variety<br />

Bash collection buckets, buying raffle<br />

tickets, bidding on the auction items and<br />

donating online,” Taylor added.<br />

Many children have lost parents in the<br />

Christchurch quake, and countless others<br />

have seen their homes and schools damaged.<br />

Variety has begun working with local<br />

communities to determine affected children’s<br />

short and long-term needs. The<br />

organisation is coordinating support on<br />

several fronts, including the replacement<br />

of medical equipment for children with<br />

special needs, providing support for schools<br />

impacted by the quake, or helping children<br />

to cope with loss.<br />

Natalie Tustian, <strong>Ford</strong> Dealer Operations Manager, Hamish Clay, <strong>Ford</strong> Business Analyst and<br />

Jenny Scott, <strong>Ford</strong> Launch and Events Executive, pose on 90 Mile Beach.<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 15

news roundup<br />

3<br />

1 <strong>Ford</strong> ViETNAM rEAcHiNG For<br />

THE STArS <strong>Ford</strong> Vietnam boldly went<br />

where no auto company has gone before<br />

with a space-aged theme to the National<br />

dealer’s Meeting Gala dinner. Using the<br />

slogan “New Era, New Frontiers to<br />

Conquer”, representatives from most <strong>Ford</strong><br />

Vietnam Ltd (FVL) departments and<br />

dealerships across the country were asked<br />

to imagine they were on board “Spaceship<br />

FVL”. In order to conquer a new era, the<br />

“crew” were told they needed teamwork,<br />

confidence, persistence, and to be decisive,<br />

overcome difficulties and take risks. The<br />

evening also featured an awards<br />

presentation for dealers; Saigon <strong>Ford</strong> did<br />

especially well, winning the Grand Achiever,<br />

Best Sales by Volume, Best Sales<br />

Performance and Grand Achiever awards.<br />

2 <strong>Ford</strong> EdGE WiNS cHiNESE MEdiA<br />

AWArdS Just a few months after its<br />

introduction to the market, the Edge has<br />

16 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

won awards from seven leading chinese<br />

auto and lifestyle media outlets, including<br />

Car magazine, Esquire magazine and the<br />

China Travel Channel. “Being honoured with<br />

so many awards so shortly after the launch<br />

is a great achievement,” said J.D. Tang,<br />

<strong>Ford</strong> China’s director of marketing, sales<br />

and service. “The <strong>Ford</strong> Edge is a truly<br />

fantastic vehicle and we are confident it will<br />

be very competitive in its segment.”<br />

3 FirST Body ANd PAiNT SHoP<br />

coNVENTioN HELd <strong>Ford</strong>’s ability to give<br />

customers a “good as new” repair service<br />

was showcased to 180 delegates from<br />

suppliers and business partners at a<br />

convention hosted by <strong>Ford</strong> India in Chennai.<br />

The event gave <strong>Ford</strong> and its partners the<br />

chance to share industry best practices and<br />

highlight the importance of having a high<br />

quality after-market service. “With the right<br />

people, the right processes and the right<br />

training, we will make sure that these best<br />

1<br />

2<br />

4<br />

practices are universally applied,” said<br />

Shane Eagle, <strong>Ford</strong> <strong>APA</strong> body shop<br />

development manager.<br />

4 LiFESTyLE MEdiA ENjoy FuN<br />

FiESTA GETAWAy <strong>Ford</strong> Motor Indonesia<br />

recently took 19 female reporters from<br />

lifestyle media including the magazines<br />

Cosmopolitan, Marie Claire, Her World, Cleo<br />

and Elle on an action-packed getaway<br />

across Bali, to spread the message that the<br />

Fiesta’s stylish design, nimble handling and<br />

fuel efficiency are perfect for the modern<br />

woman on the go. The three-day trip<br />

included a tour of a pearl farm, a yoga<br />

session, a visit to a fortune teller, wine<br />

tasting, and, of course, a shopping trip.<br />

“This event was so exciting,” said Mindy<br />

Zein, from Elle magazine. “I love the <strong>Ford</strong><br />

Fiesta, it’s so smart and fabulous!”<br />

5 <strong>Ford</strong> PHiLiPPiNES riNGS THE<br />

rEGiSTEr WiTH FiESTA FLEET<br />

SALE On February 21, <strong>Ford</strong> Group

5<br />

Philippines (FGP) registered its biggest<br />

fleet sale this year with the delivery of 22<br />

Fiestas to Air21, a logistics firm that<br />

specialises in freight and cargo forwarding<br />

services under the Lina Group of<br />

Companies. “This marks the beginning of a<br />

new and successful partnership,” said FGP<br />

President Randy Krieger. “As a delivery and<br />

logistics provider, Air21 requires reliable<br />

transportation to meet their growing<br />

customer demands. <strong>Ford</strong> can meet these<br />

demands with our wide range of products<br />

that are class leaders in quality, fuel<br />

efficiency, safety, smart design and value.”<br />

In December 2010, the <strong>Ford</strong> Fiesta was the<br />

best-selling hatchback in the Philippines.<br />

6 STudENTS SEE cArEEr<br />

oPPorTuNiTiES WiTH <strong>Ford</strong> <strong>Ford</strong><br />

Motor Company of Southern Africa<br />

(FMCSA) opened its doors to prospective<br />

future employees for its annual career day<br />

in February. <strong>Ford</strong> invited 90 high school<br />

7<br />

8<br />

students to spend a day at the Silverton<br />

Assembly Plant in Pretoria and another 35<br />

to visit the <strong>Ford</strong> Engine Plant in Struandale,<br />

Port Elizabeth. “The Careers Day programme<br />

is evidence of FMCSA’s aim to invest in the<br />

future of young people in South Africa,” said<br />

FMCSA President and CEO Jeff Nemeth.<br />

“Education forms a significant part of our<br />

commitment to corporate social<br />

responsibility.”<br />

7 THird yEAr oF driViNG SkiLLS<br />

For LiFE iN TAiWAN <strong>Ford</strong> Lio Ho (FLH)<br />

has kicked off its Driving Skills for Life<br />

programme for the third year running in<br />

Taiwan. “Transportation safety and<br />

environmental protection are two major<br />

priorities for <strong>Ford</strong> Lio Ho,” said FLH<br />

President Albert Li. “As one of the leading<br />

automotive brands in Taiwan, <strong>Ford</strong> Lio Ho is<br />

committed to help improve the driving<br />

environment. We will continue to bring this<br />

training course to more drivers in Taiwan,<br />

news roundup<br />

6<br />

through off-line training sessions and<br />

internet channels to share DSFL skills with<br />

more people and help make the roads in<br />

Taiwan both safer and greener.”<br />

8 TouGH Truck FuN AT rANGEr<br />

GyMkHANAS <strong>Ford</strong> Thailand organised a<br />

series of Ranger Gymkhanas in three<br />

provinces that showed the truck is both<br />

built tough and fun to drive. The competition<br />

was open to existing customers, who had to<br />

navigate the Rangers through a series of<br />

testing time trials. Hundreds of people<br />

turned up to watch each event, which<br />

featured plenty of food, drink and<br />

entertainment. The winners of the three<br />

gymkhanas were later invited to Bangkok as<br />

<strong>Ford</strong>’s VIP guests for the unveiling of the<br />

new Ranger at the 32nd Bangkok<br />

International Auto Show.<br />

@<strong>Ford</strong> <strong>APA</strong> March/April 2011 17

<strong>Ford</strong> faces<br />

Talking to the trainers<br />

At some point everyone needs to be taught how to do their job, and to progress in a career it is often<br />

necessary to learn new skills. We talk to the trainers about what it takes to teach.<br />

Xiaohui Fan, engine inspection supervisor,<br />

Changan <strong>Ford</strong> Mazda Engine<br />

18 @<strong>Ford</strong> <strong>APA</strong> March/April 2011<br />

raadha Madhavan, deputy manager<br />

of human resources, <strong>Ford</strong> India<br />

Wirontono jusuf, training manager,<br />

<strong>Ford</strong> Motor Indonesia<br />

What type of training do you carry out?<br />

I teach basic engine knowledge, engine construction Leadership and soft skills programmes, including com- All types of non-technical training for sales and service<br />

and engine maintenance, both in the classroom and on munication and presentation skills, leadership training, teams.<br />

the production line.<br />

and new employee orientation.<br />

What is the most important lesson you want your students to take away from a training session?<br />

All lessons are equally important, but if I had to choose,<br />

I would like them to leave my lessons passionate about<br />

their careers, as well as full of auto knowledge.<br />

What traits are important to train someone successfully?<br />

To be able to build trust with trainees. If they trust me,<br />

they will also trust that my training course will be of<br />

benefit.<br />

I want them to pick up at least one thing from every<br />

training session and implement it in their work and life.<br />

Passion, enthusiasm, willingness to share your knowledge<br />

and most importantly willingness to learn from<br />

participants.<br />

How do you make sure that your audience understands what you are teaching?<br />

I observe their faces and check they answer my questions<br />

correctly.<br />

By asking them questions, and making my sessions<br />

highly interactive, lively and informal.<br />

What is the most rewarding or interesting part of your job and why?<br />

I love engines, so the job is very interesting to me, and it<br />

is very rewarding to help trainees begin their careers as<br />

auto professionals.<br />

Every time I get to meet different types of people; I can<br />

build great relationships with participants during training<br />

sessions that continue afterwards.<br />

How do you get trainees to pay attention and realise the training is valuable?<br />

Sometimes just learning facts can be boring, so I associate<br />

the knowledge with practical skills; for example, I’ll<br />

give tips on driving and engine maintenance based on<br />

the engine theory I am talking about.<br />

I reinforce the key message that any training session<br />

can make an impact on our lives, depending on how we<br />

transfer the learning.<br />

Has anything embarrassing ever happened during a session? What was it, and how did you handle it?<br />

Curious trainees might ask a question that the trainer<br />

does not know the answer to, but that is not something<br />

to be embarrassed about; if this happens I ask for their<br />

contact details and will get back to them after consulting<br />

other professionals.<br />

While conducting One <strong>Ford</strong> behaviour training, there<br />

was an employee who said: “this will not work, it is not<br />

practical” and shared a true incident where it didn’t<br />

work. I had to tell him that one has to patiently practice<br />

in what one believes is right; emotional resilience is the<br />

key to success.<br />

What is the most interesting question you have been asked by a student?<br />

A student once asked what to do with their left foot<br />

when driving an automatic transmission car.<br />

I suggested they beat time to their music.<br />

All of their questions are interesting as it shows<br />

they are learning.<br />

If the training is about a product I want them to really<br />

understand what they are going to sell and how it compares<br />

to competitors. If I am teaching a skill, like sales, I<br />

hope they have confidence to practice what they have<br />

been taught.<br />

You need to know your target audience and how best to<br />

talk to them, so you have to understand different ways<br />

and methods to deliver the training.<br />

You need to have a connection to the audience, and be<br />

sensitive to the situation in the classroom – if I think<br />

people are starting to lose focus I’ll pause for a refreshment<br />

break so they feel sharp again.<br />

I’m sharing knowledge, and I’m also learning from the<br />

participants in the class. I like being able to better myself<br />

and contribute to other peoples’ careers.<br />

By making sure I communicate effectively right from the<br />

start and make it clear how the programme can help.<br />

It can’t always be 100 per cent perfect, but the important<br />

thing when something goes wrong is to stay calm,<br />

and explain to the participants what has gone wrong –<br />

you have to be honest with them.<br />

I’ve been asked if I have ever tried out the theories<br />

I teach. When you’re teaching, it’s always good to<br />

have practical experience!

Indonesia<br />

The Dinner and Shopaholic<br />

Workshop.<br />

Taiwan<br />

FLH President Albert Li dressed<br />

as a "Fortune God" for the start<br />

of the Year of the Rabbit.<br />

Philippines<br />

Jumping for joy at the <strong>Ford</strong> Club<br />

Philippines’ ninth anniversary.<br />

India<br />

The Rotary Club held a Picnic<br />

Car Rally to promote road safety.<br />

China<br />

Welcoming in the Year of the Rabbit.<br />

Taiwan<br />

Enjoying the special meal served<br />

by Taiwan Operating Committee<br />

members before Lunar New Year.<br />

Australia<br />

The <strong>Ford</strong> Australia IT team<br />

volunteering at Charlton after<br />

the recent floods.<br />

South Africa<br />

Employees at the unveiling of<br />

Silverton’s new body shop.<br />

Indonesia<br />

Enjoying the magic of chocolate<br />

at the Fiesta Fearless Getaway in<br />

Bali.<br />

South Africa<br />

Sales and marketing staff show<br />

support for the FMSCA ‘Think<br />

Safety’ campaign.<br />

New Zealand<br />

‘Casual dress Friday’ raised over<br />

NZD 200 for children affected by<br />

the Christchurch earthquake.<br />

India<br />

Celebrating a paintball victory.<br />

Thailand<br />

Proud winners of the annual<br />

5S competition.<br />

Indonesia<br />

Ready to take off and present<br />

awards at the Annual Dealership<br />

Conference.<br />

Taiwan<br />

Taiwan Operating Committee<br />

members serving food to thank<br />

employees for their work in 2010.<br />

India<br />

Marketing, sales and service<br />

staff at the Wild Tribe Ranch.<br />

China<br />

Dancing at the end of year party.<br />

Australia<br />

Sui Ly Kang presented with<br />

flowers to acknowledge her 12<br />

months on the United Way Board<br />

Vietnam<br />

Fun and games on stage.<br />

South Africa<br />

Cutting the ribbon to open the<br />

new body shop in Silverton.<br />

Vietnam<br />

Life’s a beach for <strong>Ford</strong> Vietnam<br />

staff.