Our endeavour is to enhance Stakeholders' Value - Uflex Ltd.

Our endeavour is to enhance Stakeholders' Value - Uflex Ltd.

Our endeavour is to enhance Stakeholders' Value - Uflex Ltd.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

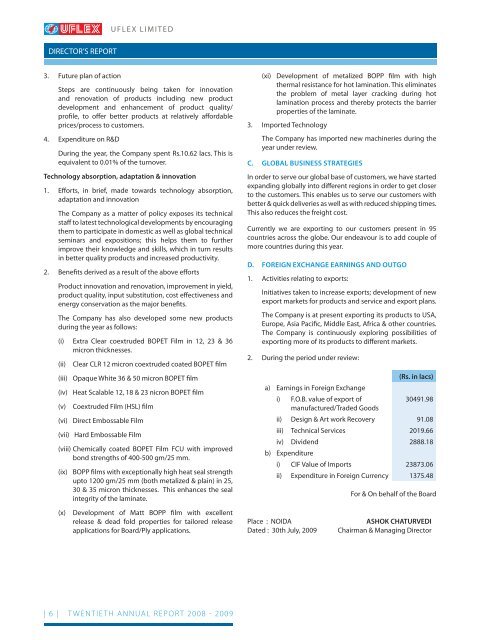

DIRECTOR’S REPORT<br />

3. Future plan of action<br />

| 6 |<br />

UFLEX LIMITED<br />

Steps are continuously being taken for innovation<br />

and renovation of products including new product<br />

development and <strong>enhance</strong>ment of product quality/<br />

profi le, <strong>to</strong> off er better products at relatively aff ordable<br />

prices/process <strong>to</strong> cus<strong>to</strong>mers.<br />

4. Expenditure on R&D<br />

During the year, the Company spent Rs.10.62 lacs. Th<strong>is</strong> <strong>is</strong><br />

equivalent <strong>to</strong> 0.01% of the turnover.<br />

Technology absorption, adaptation & innovation<br />

1. Eff orts, in brief, made <strong>to</strong>wards technology absorption,<br />

adaptation and innovation<br />

The Company as a matter of policy exposes its technical<br />

staff <strong>to</strong> latest technological developments by encouraging<br />

them <strong>to</strong> participate in domestic as well as global technical<br />

seminars and expositions; th<strong>is</strong> helps them <strong>to</strong> further<br />

improve their knowledge and skills, which in turn results<br />

in better quality products and increased productivity.<br />

2. Benefi ts derived as a result of the above eff orts<br />

Product innovation and renovation, improvement in yield,<br />

product quality, input substitution, cost eff ectiveness and<br />

energy conservation as the major benefi ts.<br />

The Company has also developed some new products<br />

during the year as follows:<br />

(i) Extra Clear coextruded BOPET Film in 12, 23 & 36<br />

micron thicknesses.<br />

(ii) Clear CLR 12 micron coextruded coated BOPET fi lm<br />

(iii) Opaque White 36 & 50 micron BOPET fi lm<br />

(iv) Heat Scalable 12, 18 & 23 nicron BOPET fi lm<br />

(v) Coextruded Film (HSL) fi lm<br />

(vi) Direct Embossable Film<br />

(vii) Hard Embossable Film<br />

(viii) Chemically coated BOPET Film FCU with improved<br />

bond strengths of 400-500 gm/25 mm.<br />

(ix) BOPP fi lms with exceptionally high heat seal strength<br />

up<strong>to</strong> 1200 gm/25 mm (both metalized & plain) in 25,<br />

30 & 35 micron thicknesses. Th<strong>is</strong> <strong>enhance</strong>s the seal<br />

integrity of the laminate.<br />

(x) Development of Matt BOPP fi lm with excellent<br />

release & dead fold properties for tailored release<br />

applications for Board/Ply applications.<br />

TWENTIETH ANNUAL REPORT 2008 - 2009<br />

(xi) Development of metalized BOPP fi lm with high<br />

thermal res<strong>is</strong>tance for hot lamination. Th<strong>is</strong> eliminates<br />

the problem of metal layer cracking during hot<br />

lamination process and thereby protects the barrier<br />

properties of the laminate.<br />

3. Imported Technology<br />

The Company has imported new machineries during the<br />

year under review.<br />

C. GLOBAL BUSINESS STRATEGIES<br />

In order <strong>to</strong> serve our global base of cus<strong>to</strong>mers, we have started<br />

expanding globally in<strong>to</strong> diff erent regions in order <strong>to</strong> get closer<br />

<strong>to</strong> the cus<strong>to</strong>mers. Th<strong>is</strong> enables us <strong>to</strong> serve our cus<strong>to</strong>mers with<br />

better & quick deliveries as well as with reduced shipping times.<br />

Th<strong>is</strong> also reduces the freight cost.<br />

Currently we are exporting <strong>to</strong> our cus<strong>to</strong>mers present in 95<br />

countries across the globe. <strong>Our</strong> <strong>endeavour</strong> <strong>is</strong> <strong>to</strong> add couple of<br />

more countries during th<strong>is</strong> year.<br />

D. FOREIGN EXCHANGE EARNINGS AND OUTGO<br />

1. Activities relating <strong>to</strong> exports:<br />

Initiatives taken <strong>to</strong> increase exports; development of new<br />

export markets for products and service and export plans.<br />

The Company <strong>is</strong> at present exporting its products <strong>to</strong> USA,<br />

Europe, Asia Pacifi c, Middle East, Africa & other countries.<br />

The Company <strong>is</strong> continuously exploring possibilities of<br />

exporting more of its products <strong>to</strong> diff erent markets.<br />

2. During the period under review:<br />

(Rs. in lacs)<br />

a) Earnings in Foreign Exchange<br />

i) F.O.B. value of export of<br />

manufactured/Traded Goods<br />

30491.98<br />

ii) Design & Art work Recovery 91.08<br />

iii) Technical Services 2019.66<br />

iv) Dividend 2888.18<br />

b) Expenditure<br />

i) CIF <strong>Value</strong> of Imports 23873.06<br />

ii) Expenditure in Foreign Currency 1375.48<br />

For & On behalf of the Board<br />

Place : NOIDA ASHOK CHATURVEDI<br />

Dated : 30th July, 2009 Chairman & Managing Direc<strong>to</strong>r