Pro 200 Series Furnace - Whip Mix

Pro 200 Series Furnace - Whip Mix

Pro 200 Series Furnace - Whip Mix

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

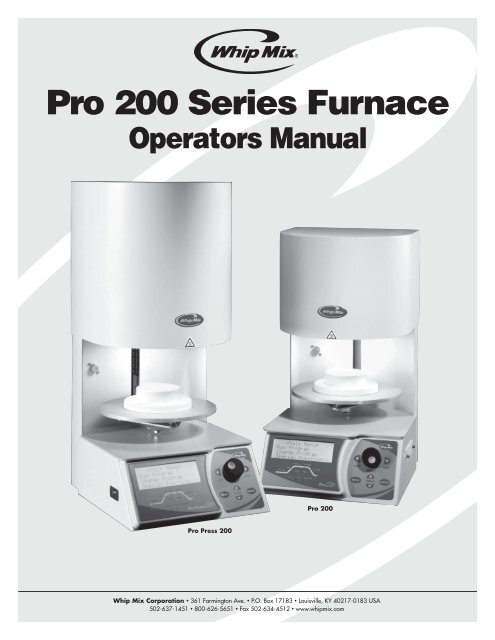

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong>Operators Manual<strong>Pro</strong> <strong>200</strong><strong>Pro</strong> Press <strong>200</strong><strong>Whip</strong> <strong>Mix</strong> Corporation • 361 Farmington Ave. • P.O. Box 17183 • Louisville, KY 40217-0183 USA502-637-1451 • 800-626-5651 • Fax 502-634-4512 • www.whipmix.com17280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 1 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualWarningsDO NOT OPERATE THIS FURNACE WITH ANY OTHERPOWER CORD.DO NOT OPERATE WITH AN EXTENSION CORD.OPERATING THIS FURNACE ON A CIRCUIT WITH OTHERFURNACES OR ELECTRICAL APPLIANCES THAT REQUIRESIGNIFICANT POWER MAY CAUSE A CIRCUIT BREAKERTO TRIP.When operating the <strong>Pro</strong> <strong>200</strong>, USE ONLY ARGON GAS.ATTACHING ANY FLAMMABLE OR NOXIOUS GAS IN THISFURNACE COULD CAUSE EXPLOSION OR PERSONALINJURY!CAUTION: METAL SURFACE IS HOT DURING OPERATION!The triangular black and yellow sticker on thefront center of the muffle hood is a warningTHAT the metallic surface can become hot to thetouch. Never place your hand on this surfaceor lean on the top of the hood when the unit isin operation.IMPORTANT: Contact your dealer or the factoryfor complete instructions on converting thefurnace between 115 VAC and 220 VAC.Hazardous live voltage present; disconnect ACMain Power cord before removing covers.WarrantyUnited States and Canada<strong>Whip</strong> <strong>Mix</strong> Corporation warrants the <strong>Pro</strong> <strong>200</strong> and <strong>Pro</strong> Press<strong>200</strong> to the original purchaser against defective workmanshipand materials under normal procedures of installation, useand service within the dental profession, for a period ofthree years or 3750 muffle hours, whichever occurs first.During which time <strong>Whip</strong> <strong>Mix</strong> Corporation will replace, repairor deny warranty coverage at its discretion. Heat treatingrefractory materials, misuse, improper installation, impropermaintenance, accident or abuse will void the warranty. <strong>Whip</strong><strong>Mix</strong> coverage only applies to <strong>Whip</strong> <strong>Mix</strong> supplied parts, andrepairs performed by <strong>Whip</strong> <strong>Mix</strong> certified repair technicians.Repairs performed during the warranty period do not extendthe warranty period. Shipping damage is only covered from<strong>Whip</strong> <strong>Mix</strong> to the intended recipient.RecommendationsNote: During shipping the muffle might absorb moisturefrom the air. So, it is recommended you heat the muffleto dry the moisture before firing any porcelain. To dry themuffle, set the idle temperature to 400° C (752° F) for onehour and 600° C (1112° F) for one hour.Follow the numbered instructions in this section to set theidle temperature to the temperatures mentioned above.<strong>Whip</strong> <strong>Mix</strong> recommends leaving the furnace on at all times.Turning the furnace off overnight may cause damage tothe muffle, contamination and void the warranty.Leaving your furnace on will also extend the life of yourfurnace. See Night Mode, page 11 for further information.InternationalTwo years parts and labor from date of purchase from dealer.The <strong>Pro</strong> <strong>Series</strong> <strong>Furnace</strong> comescomplete with:<strong>Pro</strong> Press <strong>200</strong> <strong>Pro</strong> <strong>200</strong>ManualManualCooling TrayCooling TrayFiring TrayFiring TrayPress Firing TrayPower CordPower CordTemperature Calibration CertificateTemperature Calibration Certificate Flash DriveCeramic InsertQuick Start Guide & DVDPress Air RegulatorWarranty Registration CardFlash DriveTip sheetQuick Start Guide & DVD<strong>Pro</strong>gram MagnetWarranty Registration CardQuick Cool Barb and HoseTip SheetMaster Suite DVD<strong>Pro</strong>gram MagnetQuick Cool Barb & HoseMaster Suite DVDIntended Use:The <strong>Pro</strong> <strong>200</strong> furnace is only intended for the firing ofdental porcelain materials or the pneumatic pressingof molten porcelain materials into lost wax investmentmolds. If this furnace is not used in a manner specified bythe <strong>Whip</strong> <strong>Mix</strong> Corporation, the protection provided by theproduct might be impaired.217280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 2 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualTable of ContentsChapter One — Getting StartedExternal Component Locator.................................................4Before Unpacking...................................................................5Unpacking..............................................................................5Press Version.........................................................................5Press Regulator Set-Up.........................................................5Installing the Vacuum Pump...................................................5Quick-Cool Jet Installation for<strong>Pro</strong> <strong>200</strong> <strong>Furnace</strong>s with Air Cool Jet....................................6Power.....................................................................................7Front Panel Controls...............................................................7Menu Selection Buttons.........................................................8Information Display and Entry................................................9Start <strong>Pro</strong>gram.........................................................................9Abort <strong>Pro</strong>gram........................................................................9Using the <strong>Furnace</strong>................................................................10Chapter Two — Special FunctionsSetting the Night Mode Temperature and Activation............11Change Idle Temperature.....................................................11Set Vacuum Level.................................................................12Select Constant Vacuum......................................................12Set Displayed Temperature Units (Celsius or Fahrenheit)....12Set <strong>Pro</strong>gram Start Delay......................................................13Set Music Volume Level.......................................................13Set to All Capital Text or <strong>Mix</strong>ed Upper/Lower CaseText Display.......................................................................13Select Displayed Language..................................................13Saving <strong>Pro</strong>grams to a Flash Drive (Exporting).....................14Transferring User Firing <strong>Pro</strong>grams toOther <strong>Furnace</strong>s (Importing)..............................................14Low Fusing Adjust................................................................15High Fusing Adjustment.......................................................15Testing Your <strong>Furnace</strong>............................................................16Calibrate Oven.....................................................................16Chapter Three — Change <strong>Pro</strong>gram MenuLook at a <strong>Pro</strong>gram................................................................17Add/Edit a <strong>Pro</strong>gram..............................................................18Press Firing Cycle <strong>Pro</strong>gram (<strong>Pro</strong> Press <strong>200</strong> only)...............20Copy/Change a <strong>Pro</strong>gram......................................................22Move a <strong>Pro</strong>gram...................................................................22Erase a <strong>Pro</strong>gram..................................................................22Chapter Four — Run <strong>Pro</strong>gram MenuRunning a <strong>Pro</strong>gram – Repeat <strong>Pro</strong>grams..............................23Features and Displays AvailableWhile a <strong>Pro</strong>gram is Running.............................................23The LED Graph....................................................................24Running a Pressing <strong>Pro</strong>gram...............................................25Running a Re-Press <strong>Pro</strong>gram..............................................25Chapter Five — MaintenanceCleaning The <strong>Furnace</strong>..........................................................26Argon....................................................................................26Purge/Decontamination........................................................27Trouble Shooting Guide........................................................27Vacuum Test.........................................................................28Fuses....................................................................................28If More Help is Needed.........................................................28Replacement Parts..............................................................29Technical Specifications.......................................................29<strong>Pro</strong> <strong>Series</strong> Accessories........................................................30Fahrenheit to Centigrade......................................................31Centigrade to Fahrenheit......................................................313

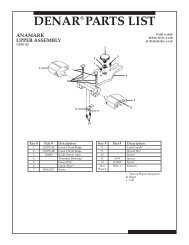

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualExternal Component LocatorTop Muffle CoverPressRegulatorAttachmentLift TableCalibration PortSelector KnobKeyboardBack CoverQuick Cool JetHose BarbPower SwitchPower Inlet PlugVacuum PumpPower OutletUSB PortFusesVacuum PumpHose BarbArgon Hose Barb417280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 4 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualChapter One — Getting StartedYou are undoubtedly eager to unpack, set up, and begin using your new furnace. Getting started will be much easier if youcarefully review the information in this chapter and follow the steps as outlined.Before Unpacking• Save the carton and packing materials. These will be usedagain if there is ever a need to ship or return equipment.• Read and save the printed shipping material packedwith your furnace — it contains valuable information!• DO NOT turn on the power to your furnace untilyou are instructed to do so, or you will damageyour furnace!• Sit the furnace on a non-flammable work surface.Unpacking• If the packaging materials and/or the furnace appear tobe damaged, please call your dealer before continuing.• Remove the furnace from the packing materials andplace it on a flat surface in the upright position.• Look up into the muffle area and locate the shippinghardware and remove it. Keep these parts in casethere is a need to ship the furnace back.Press Version• Connect the compressed air supply to the regulatorusing a standard pneumatic fitting available at mosthardware stores.• Adjust the pressure regulator to the recommendedpressure from the ceramic manufacturer.If problems arise:• Check the air supply for sufficient pressure.• Check all connections. If problems persist, writedown your serial number and call Technical Support.Press Regulator Set-UpThe <strong>Pro</strong> Press <strong>200</strong> requires compressed air to run a presscycle. Generally minimum air pressure of 63 psi/4.25BAR and a maximum of 150 psi/10 BAR. Check with theceramic manufacturer.Inputting more pressure could causean explosion!• Remove the regulatorfrom the accessorybox.• Look at the femaleend of the brass quickconnect and checkfor obstructions orforeign objects.• With the clear plastic portionfacing down, push the regulatoronto the quick connect fitting atthe back of the furnace, as shown.Make sure the quick connect isfastened.• Connect the compressed air supply to the regulatorusing a standard pneumatic fitting.If problems arise:• Check the air supply for sufficient pressure.• Check all connections.If problems persist, write down your serial numberand call Technical Support.Installing the Vacuum PumpIf you have a <strong>Whip</strong> <strong>Mix</strong> vacuum pump, plug it directly intothe furnace where indicated on the back. If the pump isnot a <strong>Whip</strong> <strong>Mix</strong> pump, you will need an adaptor.• Attach a 1/4" inch vacuum rated hose fromthe vacuum pump to the brass fitting markedVACUUM PUMP at the rear of the furnace.DO NOT attach the Argon gas system to the <strong>Pro</strong> <strong>200</strong>until the furnace is installed, operating, and the setupprocedures in the Special Functions chapter of thismanual have been completed.517280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 5 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualQuick-Cool Jet Installation for<strong>Pro</strong> <strong>200</strong> <strong>Furnace</strong>s with Air Cool JetPreparation:1. Remove the vacuum pump from its box.2. Remove the brass hose barb from the <strong>Furnace</strong>accessory box.3. Remove the muffler from the output end of thevacuum pump. (The input and output valves areidentified by arrow indicators on the vacuum pumpnear inlet or outlet.)4. Install the brass barb to output end of the vacuumpump. (Where the muffler used to be.)5. There should be two hoses included. One in theaccessory box, the other inside the vacuum pumpbox. Use the hose included in the accessory box forthe Quick-Cool Air Jet.This side goes to theQuick Cool JetInstallation:1. Push one end of the clear hose included in theaccessory box over the output barb fitting at theoutput end of the vacuum pump.2. Place the other end over the silver Quick-Cool Jetbarb located on the upper right back of the furnace.(See below.)3. Using the other pink hose, place one end over theinput side barb of the vacuum pump.4. Place the other end over the vacuum barb at the backof the furnace.5. Plug the power cord into the power outlet at the backof the furnace next to the furnace power inlet.Quick-CoolJet BarbMain PowerInletVacuum PumpPower OutletVacuumHoseBarbUsing the Quick-Cool Jet:The Quick-Cool Jet will activate when a program has beenstarted with a lower entry temperature than the furnace'scurrent temperature.1. To enable the Quick-Cool Jet, select and run aprogram with an entry temperature lower than thecurrent temperature.2. Once a program is complete, start the next programand the Quick-Cool Jet will engage.Output Barbgoes hereInputBarb617280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 6 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualPower• The furnace requires 115 Vac and 12 Amps of currentin the United States and 220–240 Vac and 6.3 Ampsof current in Europe and some parts of Asia.A special heavy-duty power cord has beensupplied with your furnace.DO NOT OPERATE WITH ANY OTHER POWER CORD.DO NOT OPERATE WITH AN EXTENSION CORD.OPERATING THIS FURNACE ON A CIRCUIT WITH OTHERFURNACES OR ELECTRICAL APPLIANCES THAT REQUIRESIGNIFICANT POWER MAY CAUSE A CIRCUIT BREAKERTO TRIP or other function problems with thefurnace. Install the heavy-duty power cord andplug the furnace into a grounded outlet.• Position the furnace so that the front is facing you.You should be able to reach the power switch on theright side of the furnace at the rear. Be sure to haveat least 8 inches on all sides of the furnace to allowsufficient airflow to keep the electronics of thefurnace cool. Do not place anything flammablenear the furnace.• Minimum ambient room temperature: 60 o F (15.5 o C).Maximum ambient room temperature: 80 o F (26.6 o C).Minimum relative humidity: 45%.Maximum relative humidity: 60%.• Turn the furnace on using the power switch. Thedisplay should light up and the unit will perform aninternal self test for about 30 seconds. The followingscreens will be displayed in this process.*USB Driver Ver*MAIN XX.XXXXXXXXXXX X.XXXtesting XX XXX XXXXXX XXWelcome<strong>Pro</strong>Press <strong>200</strong>Ver XX.XX.XXBy <strong>Whip</strong> <strong>Mix</strong>XXXXNote: The actual version number of yourfurnace will replace X.XX.XX in the aboveILLUSTRATION.Note: The Quick Start Guide provides an easy,step by step, sequence for rapid setup and initialCONFIGURATION and running your first program.Front Panel ControlsThe front panel controls and their basic functionsare described in this section. Please read thissection carefully.The front panel controls are divided into four groups:• Menu selection button calls up various functionselections:Run <strong>Pro</strong>gramChange <strong>Pro</strong>gramSpecial Functions• Information entry: Selector Knob, Next and Last• <strong>Pro</strong>gram Abort button• Table control buttons: Up/DownLastButtonSelectorKnobLCD/ScreenNextButtonTable UpButtonTable DownButtonMenuButtonAbort<strong>Pro</strong>gramButton717280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 7 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualMenu Selection ButtonsThe three menu selection items (Run <strong>Pro</strong>gram, Change<strong>Pro</strong>gram and Special Functions) will display differentoptions. The menu options can be seen by turning theSelector Knob.Run <strong>Pro</strong>gram — Press the Run <strong>Pro</strong>gram Selection to:• Select a program to run.Change <strong>Pro</strong>gram — the following actions may be initiatedby first pressing the Change <strong>Pro</strong>gram item from the MainMenu, then turning the Selector Knob to display thefollowing options:• Look at a program• Add/Edit a program• Copy/change a program• Move a program• Erase a programSpecial Functions — press the Selector Knob and turnthe Selector Knob to one of the following actions:• Start Night mode• Change Idle temperatures• Set vacuum level• Select degree C (Centigrade, centimeters),or F (Fahrenheit, inches)• Set program start delay• Set Night mode temperature• Select between constant vacuum pump orintermittent cycle vacuum pump• Change volume level of sounds• Select upper or lower case letters on the display• Select Displayed Language(English, French, German, Italian, Spanish)• Cal Low Fusing• Cal High Fusing• Cal Press (On <strong>Pro</strong> Press Only)• Copy firing programs from <strong>Furnace</strong> to Memory Card(Export <strong>Pro</strong>grams)• Copy firing programs from Memory Card to <strong>Furnace</strong>(Import <strong>Pro</strong>grams)• Export Settings• Import Settings• Test <strong>Furnace</strong>• Calibrate Oven817280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 8 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualInformation Display and EntryDISPLAY — All information and user prompts will beshown on the display (four lines, twenty characters each).SELECTOR KNOB — Turn the Selector Knob left or rightto select menu options or to adjust parameters.NEXT — Press the Next button to proceed to the nextstep within a function or program. (OR just push theSelector Knob inward to proceed).LAST — Press this button to return to the preceding stepwithin a function or program. If a program is not displayedthen the furnace will beep to indicate an error.TABLE UP — Press the up arrow button to manuallyraise the table. Press the up arrow button a second timeand the table will stop.TABLE DOWN — Press the down arrow button tomanually lower the table. Press the down arrow buttona second time and the table will stop.The table control button will not operate while a programis running.Start <strong>Pro</strong>gram• Immediately After Power-On Self-Test Completes —Rotate the Selector Knob to select a <strong>Pro</strong>gram, thenpress the Selector Knob to initiate the <strong>Pro</strong>gram.• Immediately After a Previous <strong>Pro</strong>gram Completes —Pressing the Selector Knob after a program hasjust finished will restart the same program. Or rotatethe Selector Knob to a new <strong>Pro</strong>gram selection andpress the Selector Knob to initiate the <strong>Pro</strong>gram.Abort <strong>Pro</strong>gram• Press the Abort key on the Keypad. The temperaturewill begin dropping to Idle temp and the Table willautomatically lower.917280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 9 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualUsing the <strong>Furnace</strong>After the furnace has completed the self-test at power up,the Firmware Version appears on the screen, then theDisplay prompts the entry of a <strong>Pro</strong>gram number for firing.Press the Menu button to bring up the Main Menu, thenSelect the Special Functions menu item and proceed withthe initial setup of essential default values for functions like:• Idle Temperature• Vacuum Threshold Level for Intermittent Vacuum mode• Temperature Display Units (C or F)• <strong>Pro</strong>gram Start Delay Time (Default is none)• Night Mode Temperature• Constant Vacuum Pump(Default is “NO” for Intermittent Vacuum)• Sound Volume Adjust• Capital Letter Display (Default is mixed upper andlower case display)• Displayed LanguageNote: It is very important to set up the operatingFEATURES of the furnace before you attempt toprogram the furnace or run programs. For bestRESULTS in learning to use your new furnace,use the following steps, in this order:1. Set up the operating features of the furnaceby reading and following the instructions inChapter 2 — Special Functions. This is VERYIMPORTANT because these operating featureswill affect how you enter and run programs.2. Learn to program the furnace by readingChapter 3 — Change <strong>Pro</strong>gram. Enter a fewof your own programs.3. Read Chapter 4 — Run <strong>Pro</strong>gram to understandhow to run programs and what features areavailable while running a program.1017280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 10 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualChapter Two — Special FunctionsTo look at or change a function, press the SpecialFunctions item from the Main Menu. Turn the SelectorKnob clockwise or counterclockwise until the desiredfunction is displayed. Press the Selector Knob OR theNext button to look at or change this function. Eachfunction will be described in this chapter.Most Special Functions can be performed while aprogram is running, however this is not recommendedbecause changing the operating features could affecthow the current program runs.Setting the Night Mode Temperatureand ActivationThe furnace has a Night Mode feature that will reducethe temperature in the muffle and raise the lift to preventmoisture build up.The Night Mode can be started from idle mode or whilea program is running.The furnace will automatically enter Night Mode if nobuttons have been pressed for 2 hours, or 45 minuteshave passed since the last run program and no buttonshave been pressed.The furnace comes from the factory with the Night Modetemperature set at 150° C (302° F). This temperature maybe adjusted from 0 to 400° C (752° F).If Night Mode is activated while a program is running, thefurnace will go to the night mode temperature after thecompletion of the program and will maintain the NightMode temperature until any button is pressed or thepower is turned off.To adjust the Night Mode temperature:1. From the Main Menu, press the Special Functionsitem.2. Turn the Selector Knob until the display readsNIGHT MODE TEMP.3. Press the Next button to look at or change the nightmode temperature.4. Turn the Selector Knob to change the temperatureas desired.5. Press the Next button to enter the temperature. Youwill be returned to the Main Menu automatically.After the Night Mode Temperature has been set, followthese steps to activate night mode from idle mode orduring a program.1. From the Main Menu, select the Special Functionitem. Turn the Selector Knob to the displayeditem Night Mode.2a. Push the Selector Knob OR press the Next buttonto activate Night Mode.2b. To start Night Mode at the end of the program whilea program is running.Turn the Selector Knob to NEXT = NIGHT MODE andpress the Selector Knob or Next button.* Special Functions> Night ModeChange Idle TempSet Vacuum LevelChange Idle TemperatureThe idle temperature is the temperature the furnace willmaintain between programs. The furnace comes from thefactory with the idle temperatures set at 0° C, so you mustenter a temperature for this feature to suit your needs.1. Press the Menu button.2. Select Special Functions, push Selector Knob ORpress Next button3. Turn the Selector Knob to displayCHANGE IDLE TEMP.4. Push Selector Knob OR press the Next button tolook at or change the idle temperature.5. The current setting will be displayed. Turn theSelector Knob to change to the desired temperature.6. Push the Selector Knob OR press the Next buttonto enter the temperature. You will be returned to theMain Menu automatically.Note: During shipping the muffle might absorbmoisture from the air. So, it is recommendedyou heat the muffle to dry the moisturebefore firing any porcelain. To dry the muffle,set the idle temperature to 400° C (752° F) forone hour and then 600° C (1112° F) for one hour.It is also recommended you keep the furnaceON with sufficient night mode temperature toprevent moisture from accumulating insidethe muffle. The recommended temperatureis a minimum of 150° C (302° F). If leaving the Labfor an extended period of time, you may turnthe furnace off with the table in the closedposition. Before firing porcelain again, gothrough this DRY OUT procedure.1117280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 11 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualSet Vacuum LevelThe factory setting for vacuum is 71 cm of mercury. Theacceptable range is from 22 cm to 74–75 cm of mercuryor 11.0 inches to 30.0 inches of mercury.If the furnace does not pull a minimum vacuum of 10 incheswithin 20 seconds of calling for it, the program will beaborted and the furnace will display "Vacuum Error.”Additionally, if the target vacuum level has not beenreached within 1.5 inches of the vacuum setting by 100seconds, the program will be aborted and a warningscreen will be displayed, indicating a vacuum error. (seepage 31 for error codes)If Continuous VAC Pump has been selected by usingthe Special Functions menu, the vacuum pump will runthroughout the vacuum cycle at full vacuum. If ContinuousVAC Pump has not been selected, the vacuum pump willshut off after the target level has been reached and atleast 5 seconds have elapsed. The vacuum pump will berestarted when the vacuum level has dropped to 1 inchbelow the Vacuum setting value.To set the vacuum level for all programs do the following:1. Press the Menu button.2. Select Special Functions, push Selector Knob ORpress Next button.3. Turn the Selector Knob until SET VACUUM LEVELis displayed.4. Push Selector Knob OR press the Next button tolook at or change the vacuum level.5. The current setting will be displayed. Turn theSelector Knob to change this value.6. Push Selector Knob OR press the Next button toaccept the new value. You will be returned to theMain Menu automatically when the Selector Knobor Next button is pushed. The furnace may be setto display all values using the metric system withdegrees in Centigrade and vacuum in centimetersof mercury OR to display all values using theAmerican/English (standard) system of degrees.Fahrenheit and vacuum in inches of mercury.The furnace uses an absolute vacuum sensor. With anabsolute sensor, vacuum adjustments are not necessaryat high altitudes.Select Constant VacuumSelecting constant vacuum will cause the vacuum pumpto run continuously during the vacuum cycle of a program.1. Press the Main Menu button.2. Select Special Functions, push the Selector KnobOR press the Next button.3. Turn the Selector Knob until the display readsCONSTANT VAC PUMP.4. Push the Selector Knob OR press the Next button.5. Turn the Selector Knob to display YES or NO.A selection of yes will cause the vacuum pump to runcontinuously during the vacuum cycle of a program.A selection of no will allow the vacuum pump to turn offand on to maintain the set vacuum level.Note: If intermittent vacuum is selected, butthe vacuum pump runs continuously duringthe program cycle, the vacuum level is settoo high. The actual level is within 3% of theselected level, but the pump cannot reach thefull selected level. This can be corrected byreducing the vacuum level.Set Displayed Temperature Units(Celsius or Fahrenheit)1. Press the Menu button.2. Select Special Functions, push the Selector KnobOR press the Next button.3. Turn the Selector Knob until TEMP IN C OR F?is displayed.4. Push the Selector Knob OR press the Next button tolook at or change the measurement system in use.5. TEMP CENTIGRADE? Will be displayed. Turn theSelector Knob to select YES for metric Centigrade units,or if you select NO the furnace will automatically set toFahrenheit units (American/English) (standard) units.6. Push the Selector Knob OR press the Next buttonto save the selection. You will be returned to theMain Menu automatically.1217280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 12 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualSet <strong>Pro</strong>gram Start DelayThe furnace has a unique feature that allows the operatorto program a delay to occur before the start of all programs.This delay occurs before the entry time set into eachprogram begins. This feature may be changed withoutaffecting the programs or calibrations stored in the furnace.1. Press the Main Menu button.2. Select Special Functions, push the Selector KnobOR press the Next button.3. Turn the Selector Knob until the second line on thedisplay reads PROG START DELAY.4. Press the Next button to look at or change the startdelay time.5. The display will read TIME = 0.00 or any time delaypreviously entered. Turn the Selector Knob tochange the time as desired.6. Push the Selector Knob OR press the Next buttonto save your selection. You will be returned to theMain Menu automatically.Note: The delay feature subtracts from thetime it takes to heat the muffle to the entryTEMPERATURE so the delay time may appearSHORTER than originally programmed. As anexample; let’s assume the delay is set for 30minutes, the entry temperature is 500° C, andthe time it takes the furnace to reach 500° Cfrom the point which you entered the delayis 15 minutes. The furnace would count down15 minutes to the beginning of the programand then would begin heating to the entryTEMPERATURE. This gives us a total of 30 minutesbefore the table rises to the muffle.Set Music Volume Level1. Press the Special Functions button.2. Turn the Selector Knob until display readsCHANGE MUSIC VOLUME.3. Push the Selector Knob OR press the Next key. Continueto turn the Selector Knob to the desired volume. Thecursor will appear to the left of the volume selected:4. Rotate the Selector Knob and a sequence of toneswill begin playing to give you an audible referencefor the corresponding sound level. When the volumelevel is set to your liking, push the Selector Knob ORpress the Next button to save your selection. You willbe returned to the Main Menu automatically.Set to All Capital Text or <strong>Mix</strong>edUpper/Lower Case Text Display1. Press the Special Functions button.2. Turn the Selector Knob until display readsCAPITAL LETTER?3. Push the Selector Knob OR press the Next button.4. If you want all Capital Letters displayed, rotate theSelector Knob to Yes and push the Selector KnobOR press the Next button. If you do not want all Capitalletters, rotate to No for mixed upper/lower case lettersand press the Selector Knob OR press the Next button.Select Displayed Language1. Press the Special Functions button.2. Turn the Selector Knob until the display readsSELECT LANGUAGE.3. Push the Selector Knob OR press the Next button.4. Choose from the following list of languages:> EnglishFrancaisDeutchItalianoEspanol5. Rotate the Selector Knob until the cursor points tothe desired language and push the Selector KnobOR press the Next button to save your selection. Youwill be returned to the Main Menu automatically.1317280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 13 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualSaving <strong>Pro</strong>grams to a Flash Drive(Exporting)1. Place the Flash Drive in the USB slot on the left side ofthe furnace with the shiny metal contact facing upward.2. Select the Special Functions item from the Main Menu.3. Turn the Selector Knob until the display readsEXPORT PROGRAM, then press the Next button.4. The display will show Check USB Driver, thenExporting >>>>>>>5. The furnace will signal the end of the transfer withan audible tone.Transferring User Firing <strong>Pro</strong>gramsto Other <strong>Furnace</strong>s (Importing)Once you have exported programs to the Flash Drive,either via the furnace EXPORT PROGRAM function ORvia the PC Software, you can load these programs on adifferent furnace or return them to the same furnace.1. Place the Flash Drive in the USB slot on the left side ofthe furnace with the shiny metal contact facing upward.2. Select the Special Functions item from the Main Menu.3. Turn the Selector Knob until the display reads IMPORTPROGRAM, then press the Next button.4. The display will show Check USB Driver, thenImporting >>>>>>>5. The furnace will signal the end of the transfer with anaudible tone.1417280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 14 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualLow Fusing AdjustCalibration (800° C/1470° F or below)1. Select the Special Functions item from the Main Menu.2. Turn the Selector Knob until display readsCAL LOW FUSING.* Special FunctionsSelect Language> Cal Low FusingCal High Fusing3. Press the Next button.The display will show the current Low Fusing porcelaincalibration offset. For new furnaces this should be “0”. Ifthe Selector Knob is rotated clockwise note that the “0”value changes to a positive value, and if rotated counterclockwiseit changes to a negative value. If you need toraise ALL your Low Fusing program firing temperatures bythe same amount you can dial in a positive value then pressthe Next button to accept the offset value. Conversely,if you want to lower ALL your Low Fusing program firingtemperatures by the same amount, dial in a negative valueand press the Next button to accept the offset value.High Fusing AdjustmentCalibration (801° C/1471° F or above)1. Select the Special Functions item from the Main Menu.2. Turn Selector Knob until display readsCAL HIGH FUSING.* Special FunctionsSelect Language> Cal Low FusingCal High Fusing3. Press the Next button.The display will show the current High Fusing porcelaincalibration offset. For new furnaces this should be “0”. Ifthe Selector Knob is rotated clockwise note that the “0”value changes to a positive value, and if rotated counterclockwiseit changes to a negative value. If you need to raiseALL of your High Fusing program firing temperatures bythe same amount you can dial in a positive value then pressthe Next button to accept the offset value. Conversely, ifyou want to lower ALL of your High Fusing program firingtemperatures by the same amount, dial in a negative valueand press the Next button to accept the offset value.Example: If your porcelain appears to be overfired by 25°,you would enter a negative (-25) twenty-five degree value tolower the effective firing temperature of ALL the Low Fusingprogram.4. Turn the Selector Knob to enter the number ofdegrees you would like to adjust the temperature.Low Temp Adj0C(-50C - +50C)5. Press the Next button. The adjustment will be storedand you will be returned to the main menu.Example:If porcelain looks under-fired, increase temperature.If porcelain looks over-fired, decrease temperatureExample: If your porcelain appears to be overfired by 25°,you would enter a negative (-25) twenty-five degree valueto lower the effective firing temperature of ALL the LowFusing programs.4. Turn the Selector Knob to enter the number ofdegrees you would like to adjust the temperature.High Temp Adj0C(-50C - +50C)5. Press the Next button. The adjustment will be storedand you will be returned to the main menu.Example:If porcelain looks under-fired, increase temperature.If porcelain looks over-fired, decrease temperature1517280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 15 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualTesting Your <strong>Furnace</strong>The <strong>Pro</strong> <strong>Series</strong> <strong>Furnace</strong>s are capable of performingseveral tests to aid in diagnosing the furnace should aproblem occur. A TOPS technician or Technical Supporttechnician may ask you to run one or more of these teststo aid in diagnosing the problem. The tests include:• Vacuum test• Muffle test• Motor Up test• Motor down test• Muffle hour reading. (The muffle hour readingis incremented by 1 for each hour the muffletemperature is above 605° C.)• Press test (in <strong>Pro</strong>Press <strong>200</strong>)To Begin Test:1. Select the Special Functions item from the Main Menu.2. Turn the Selector Knob until the display readsTEST FURNACE.3. Push the Selector Knob OR press the Next button.4. Turn the Selector Knob until the test you require isdisplayed.5. Push the Selector Knob. (The individual test, whichwas selected, will now begin.)6. Pressing the Next button will pause the test. Pressingthe Next button again will restart.7. Pressing the Menu button will end the test and returnyou to the Main Menu.Calibrate OvenCaution: This item of the Special Functions menuis typically reserved for <strong>Whip</strong> <strong>Mix</strong> certifiedtechnicians. Entering numbers other than theFOUR described below could result in programand calibration loss.With this screen it is possible to activate the followingfeatures:• Fast Cool With Vacuum On (for cooling muffleto entry temp between programs) Lowers the liftand runs the vacuum pump until the furnace reachesthe entry temperature for a program. To activate thisfunction, start a program with an entry temperaturelower than the current temperature.• Enable <strong>Pro</strong>gram Password <strong>Pro</strong>tection (Call <strong>Whip</strong><strong>Mix</strong> TOPS Technicians.)• On <strong>Pro</strong> Press <strong>200</strong>; use Timed Press; Yes/NoChanges preference between Re-Press and TimedPress, press programs are factory set and includevacuum.• Load Code from “Flash Drive” Enables you to orderand upgrade software.To access one of the four functions, do the following:Password FunctionNumbers1. Fast Cool with Vacuum On Password 3152. Enable <strong>Pro</strong>gram Password <strong>Pro</strong>tection<strong>Pro</strong>tects all programs from alteration3. Select Timed Press or Re-press TimeIf Yes is selected, then you will beprompted to enter the Repress Time.In this program 4 minutes will automaticallybe added to the time you enter.The default program is timed press whichdoes not add and additional 4 minutes.(Call <strong>Whip</strong> <strong>Mix</strong>TOPS Technician)Password 3154. Load code from Flash Drive (Call <strong>Whip</strong> <strong>Mix</strong>TOPS Technician)Push the Selector Knob OR press the Next button. Enterthe password and access the selected function.1. Select the Special Functions item from the Main Menu.2. Turn the Selector Knob to CALIBRATE OVEN.3. Push the Selector Knob OR press the Next button.4. Turn the Selector Knob to select the numericalpassword needed.1617280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 16 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualChapter Three — Change <strong>Pro</strong>gram MenuThe Master Suite DVD provided with the furnace is analternate means of adding or editing programs using aPC application. A memory stick is then used to transferthe programs from the PC to the furnace. Refer to theseparate instructions provided in pdf format on the DVD.The following is an example of a program descriptor. The<strong>Pro</strong>gram Number is displayed first, then a “-” character.The next fifteen characters contain the name entered todescribe this program.The Change/Edit <strong>Pro</strong>gram menu item allows you to add,change, move, copy, print, or erase programmed firingcycles. This mode is reached by selecting the Change/Edit <strong>Pro</strong>gram Item from the Main Menu.All of the features described here may be performed whilea program is running. Both the <strong>Pro</strong> <strong>200</strong> and <strong>Pro</strong> Press <strong>200</strong>furnaces use a unique method of numbering and namingprograms to help the operator select the correct programto run.The <strong>Pro</strong>gram Number is shown first (0-199), followed bythe <strong>Pro</strong>gram Name.12 STNS- Body AddIn the example, the user has entered BODY ADD toindicate that this is a body add-on program. The followingexamples show how a user could make programidentification easy:12 SYNS- BODY ADD [Synspar porcelain body add program]13 SYNS- GLAZE [Synspar porcelain glaze program]20 VITA- DE GAS [Vita porcelain de-gas program]Look at a <strong>Pro</strong>gramThe Look at a <strong>Pro</strong>gram feature allows the operator to viewa program without changing any values:1. Select the Change <strong>Pro</strong>gram from the Main Menu.2. Turn the Selector Knob until LOOK AT PROGRAMis displayed.3. Push the Selector Knob OR press the Next buttonto select this feature.4. Turn the Selector Knob to find the program youwish to view.5. Push the Selector Knob OR press the Next button tocontinue viewing each step through the program.* Look At <strong>Pro</strong>gram *Dry Time 10:00Entry Temp450CPress Knob = ContinueThis firing parameter cannot be changed while looking ata program.Pushing the Selector Knob OR pressing the Nextbutton will let you look at the next parameter in aprogram. Pressing the Last button will let you look at thepreceding item in a program.* Look At <strong>Pro</strong>gram *Rate Rise45C/MHold Temp940CHold Time 00:01:00When the last item in a program has been viewed thedisplay will return to the Main Menu.The first line displays a parameter in the firing cycleprogram and its value.1717280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 17 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualAdd/Edit a <strong>Pro</strong>gramAdd/Edit a <strong>Pro</strong>gram is usedto enter a new program orEdit a pre-existing program.This selection will describehow to enter either a 1-Stageor a 2-Stage program.The first four firing cycles are normal porcelain firingcycles. The following procedure describes how to enter anormal porcelain program.1. Press the Main Menu button.2. Select the CHANGE PROGRAM item and push theSelector Knob OR press the Next button.3. Turn the Selector Knob until ADD/EDIT PROGRAMis displayed.4. Push the Selector Knob OR press the Next button.A cursor pointing to the current program number willbe displayed. If there is a name displayed after theprogram number this is a pre-existing program whichyou may edit by selecting it.5. To Add a program, rotate the Selector Knob to find theprogram number to which you want to add your newprogram. If you select a program number that alreadyhas a program entered, you will overwrite the existingprogram with the new one by entering new values.Select <strong>Pro</strong>gram> 001–ENTRYTIMEPress Knob = ContinueHEAT RISEVACUUMHOLD TIMECOOLTIME6. Push the Selector Knob OR press the Next button toselect a program for Addition or Editing. The displaywill present the “stage” type selection as below:Select Type> 1–stage2–stagePressIf the program you wish to Add requires only a singleRate Rise and Hold Temperature, select 1-Stage. Ifthe program requires an initial Rate Rise and HoldTemperature, followed by a secondary Rate Rise andHold Temperature, select 2-Stage.Push the Selector Knob OR press the Next buttonto select the program type.7. The display will change as shown below:* Add/Edit <strong>Pro</strong>gram *Enter <strong>Pro</strong>gram Name001 –Normal PorcelainThe ^ symbol under the line identifies the currentcharacter position being entered. Rotate the SelectorKnob to bring up the desired character, then push theSelector Knob OR press the Next button to advance tothe next character in the <strong>Pro</strong>gram Name. You may enterup to 15 characters. If you do not require all 15 charactersthen simply hold down the Next button to space throughthe unneeded characters or press the Selector Knoband jump to the first Parameter entry screen.8. Dry Time EntryDry Time is the time it takes the table to go from the fulldown/open position to the table up/closed position.This will occur with several pauses in up motion duringthe travel to allow the work piece to dry gradually.The range of values is 00 minutes, 00 seconds, to amaximum of 99 minutes.Rotate the Selector Knob to select the time value,then push the Selector Knob OR press the Nextbutton to store the parameter.* Add/Edit <strong>Pro</strong>gram *Dry Time 00:03:00(00:00:00–01:39:00)9. Entry TemperatureEntry Temperature is the temperature at which the tableis closed completely and the temperature rise begins.The range of values is 25° C (77° F) to a maximum of980° C (1796° F).Rotate the Selector Knob to select the temperaturevalue, then push the Selector Knob OR press theNext button to store the parameter.* Add/Edit <strong>Pro</strong>gram *Entry Temp400C(25C – 980C)10. Rate RiseRate Rise or ramp up, is the number of degrees perminute the temperature will rise after the table hasclosed.The range of values is 0° C/Minute (0° F) to amaximum of 100° C/Minute (180° F).Rotate the Selector Knob to select the heat ratevalue, then push the Selector Knob OR press theNext button to store the parameter.* Add/Edit <strong>Pro</strong>gram *Rate Rise40C/M(00C/M – 100C/M)1817280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 18 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations Manual11. Hold TemperatureHold Temperature or the top temperature is the final,highest temperature in a 1-Stage <strong>Pro</strong>gram, and anintermediate stopover temperature in a 2-Stage<strong>Pro</strong>gram.The range of values is 400° C (752° F) to a maximumof 1<strong>200</strong>° C (2192° F).Rotate the Selector Knob to select the temperaturevalue, then push the Selector Knob OR press theNext button to store the parameter.* Add/Edit <strong>Pro</strong>gram *Hold Temp920C(400C – 1<strong>200</strong>C)12. Hold TimeHold Time is the length of time the furnace stays atthe top Hold Temperature. If the <strong>Pro</strong>gram is a 2-Stage<strong>Pro</strong>gram, there will be separate Hold Times for bothHold Temperature 1 and Hold Temperature 2.The range of values is 00 hours, 00 seconds, to amaximum of 18 hours.Rotate the Selector Knob to select the time value,then push the Selector Knob OR press the Nextbutton to store the parameter.* Add/Edit <strong>Pro</strong>gram *Hold Time 00:00:30(00:00:00–99:00)Note: If you are Adding a 2-Stage <strong>Pro</strong>gram, theRate Rise 2, followed by the Hold Temperature 2,and the Hold Time 2 parameters will appear here.If not, the Table Down Temperature will appearnext.13. <strong>Pro</strong>gram Fusing Adjustment ParameterAdd/Edit <strong>Pro</strong>gramFuse Adjust>NoIMPORTANT NOTE: The Fusing Adjustment <strong>Pro</strong>gramPARAMETER is similar to the HIGH FUSING ADJUSTand LOW FUSING ADJUST functions from the SpecialFunctions Menu in that any VALUE entered herewill either add to, or subtract from, the HoldTemperature PARAMETER in the program. The<strong>Pro</strong>gram level Fuse Adjust parameter adjuststhe Hold Temperature ONLY FOR THE PROGRAM ITIS ENTERED IN, WHERAS THE SPECIAL FUNCTIONS/ HIGHFUSING ADJUST AFFECTS ALL PROGRAMS WITH A HOLDTEMPERATURE >800 C AND THE SPECIAL FUNCTIONS/LOWFUSING ADJUST AFFECTS ALL PROGRAMS

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations Manual17. Use VacuumThe default value for Use Vacuum is YES.First, enter the Level of Vacuum desired. This is the valueat which the pump will cut off if you are using IntermittentVacuum (See Special Functions selections for choosingIntermittent or Constant Vacuum) If the value drops morethan 2 cm of mercury lower than the value specified hereduring Intermittent Vacuum use, the vacuum pump willautomatically start and run until the programmed Level isonce again reached, then automatically cut off. This willoccur as many times as required.The range of Vacuum Level settings is 28 cm of mercuryto a maximum of 75 cm of mercury, although pumpsweaken over time and usage. 71 cm of mercury is thedefault Level.Rotate the Selector Knob to select the vacuum value,then push the Selector Knob OR press the Nextbutton to store the parameter.18. Start VacuumAdd/Edit <strong>Pro</strong>gramUse Vacuum>YesThis parameter controls when the vacuum pumpcomes on. The selections are made by rotating theSelector Knob as in the example below. The rangewill be different depending on the values already putinto the program.• Rate Rise (1)• Hold Time (1)• Rate Rise 2 (2-Stage <strong>Pro</strong>gram)• Hold Time 2 (2-Stage <strong>Pro</strong>gram)Range: 406 C to 900 CRange: 0 to 30 SecondsRange: 900 C to 1025 CRange: 0 to 4 MinutesRotate the Selector Knob to select the setting, thenpush the Selector Knob OR press the Next buttonto store the parameter.19. Release VacuumThis parameter controls when the vacuum is released,and either air or argon (If Use Argon = Yes) is allowedto enter the muffle. The selections are made byrotating the Selector Knob as in the example below.The range will be different depending on the valuesalready put into the program.• Rate Rise (1)• Hold Time (1)• Rate Rise 2 (2-Stage <strong>Pro</strong>gram)• Hold Time 2 (2-Stage <strong>Pro</strong>gram)• When Table OpensRange: 425 C to 900 CRange: 0 to 30 SecondsRange: 900 C to 1025 CRange: 6 Seconds to 4 MinutesRotate the Selector Knob to select the setting, thenpush the Selector Knob OR press the Next button tostore the parameter. This is the final parameter. Youwill automatically be returned to the Main Menu.Press Firing Cycle <strong>Pro</strong>gram(<strong>Pro</strong> Press <strong>200</strong> only)The following procedures describe how to enter apressing program:1. Press the Main Menu button:2. Select the CHANGE PROGRAM Item and push theSelector Knob OR press the Next button.3. Turn the Selector Knob until ADD/EDIT PROGRAMis displayed.4. Push the Selector Knob OR press the Next button.5. A cursor pointing to the current program number willbe displayed. If there is a name displayed after theprogram number this is a pre-existing program whichyou may Edit by selecting it.To Add a program, rotate the Selector Knob to findthe program number you want to add your newprogram into. If you select a program number thatalready has a program entered, you may overwritethe existing program with the new one.6. Push the Selector Knob OR press the Next button toselect a program for Addition or Editing. The displaywill present the stage type selection as below:* Add/Edit <strong>Pro</strong>gram *Enter <strong>Pro</strong>gram Name001 –If the program you wish to Add requires only a singleRate Rise and Hold Temperature, select 1-Stage.If the program requires an initial Rate Rise andHold Temperature, followed by a secondary RateRise and Hold Temperature, select 2-Stage. Pushthe Selector Knob OR press the Next button toselect the program type.7. The display will change as shown below:* Add/Edit <strong>Pro</strong>gram *Enter <strong>Pro</strong>gram Name008 –The ^ symbol under the position identifies the currentcharacter being entered. Rotate the Selector Knobto bring up the desired character, then push theSelector Knob OR press the Next button to advanceto the next character in the <strong>Pro</strong>gram Name. You mayenter up to 15 characters. If you do not require all15 characters then simply continue to press the Nextbutton until the cursor is all the way to the right sideand the display changes to the one below:Select Type1–stage2–stage> Press2017280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 20 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations Manual8. Entry TemperatureEntry Temperature is the temperature at which thetable will close completely.The range of values is 25° C (77° F) to a maximum of980° C (1796° F).Rotate the Selector Knob to select the temperaturevalue, then push the Selector Knob OR press theNext button to store the parameter.9. Rate RiseRate Rise is the number of degrees per minute thetemperature will rise after the table has closed.The range of values is 0° C/Minute (0° F) to amaximum of 100° C/Minute (180° F).Rotate the Selector Knob to select the heat ratevalue, then push the Selector Knob OR press theNext button to store the parameter.10. Hold TemperatureHold Temperature is the final, highest temperaturein a 1-Stage <strong>Pro</strong>gram, or an intermediate stopovertemperature in a 2-Stage <strong>Pro</strong>gram.The range of values is 400° C (752° F) to a maximumof 1<strong>200</strong>° C (2192° F).Rotate the Selector Knob to select the temperaturevalue, then push the Selector Knob OR press theNext button to store the parameter.11. Hold TimeHOLD TIME is displayed. This is the amountof time desired to hold the porcelain at the finaltemperature, before the furnace begins to press.The range of values is 00 minutes, 00 seconds, to amaximum of 99 minutes.Rotate the Selector Knob to select the time value,then push the Selector Knob OR press the Nextbutton to store the parameter.Note: If you are Adding a 2-Stage <strong>Pro</strong>gram, the RateRise 2, followed by the Hold Temperature 2, andthe Hold Time 2 parameters will appear here. Ifnot, the Table Down Temperature will appear next.Note: Re-Press is selected in the Calibrate Ovensection of this Manual, using password 315.12. Fusing Adjustment ParameterFuse Adjust?> UnderfiresIMPORTANT NOTE: The Fusing Adjustment <strong>Pro</strong>gramPARAMETER is similar to the HIGH FUSING ADJUST andLOW FUSING ADJUST functions from the SpecialFunctions Menu in THAT any value entered herewill either add to, or subtract from, the HoldTemperature PARAMETER in the program. The <strong>Pro</strong>gramlevel Fuse Adjust PARAMETER adjusts the HoldTemperature ONLY FOR THE PROGRAM IT IS ENTERED IN,WHERAS THE SPECIAL FUNCTIONS/ HIGH FUSING ADJUSTAFFECTS ALL PROGRAMS WITH A HOLD TEMPERATURE>800° C (1472° F) AND THE SPECIAL FUNCTIONS/LOW FUSINGADJUST AFFECTS ALL PROGRAMS

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualCopy/Change a <strong>Pro</strong>gramThe Copy/Change a program feature allows a program tobe copied from one program number to another and thenchanged. This feature is very useful when there are onlyminor differences between programs.<strong>Pro</strong>cedures:1. Press the Main Menu button.2. Select Change <strong>Pro</strong>gram, push the Selector KnobOR press the Next button.3. Turn the Selector Knob until COPY/CHANGE PROGis displayed. Push Selector Knob OR press the Nextbutton to select this feature.4. COPY FROM: is displayed. The second line displays aprogram number and name. Turn the Selector Knobto find the program to be copied. Push the SelectorKnob OR press the Next button to continue.5. COPY TO: is displayed. Turn the Selector Knob toselect a location for the copied program. If a programthat is already entered is selected, you will write overthe existing program. Push the Selector Knob ORpress the Next button.6. At this point, changes to the program may be madein the same manner as described in the sectionAdd a <strong>Pro</strong>gram on page 19. Refer to that section forinstructions specific to each type of firing program.Note: The name of the new program must bechanged because the furnace does not allowDUPLICATE program names.Move a <strong>Pro</strong>gramThe Move program feature allows a program to be movedfrom one number to another. This feature is useful forgrouping programs for operator convenience.<strong>Pro</strong>cedure:1. Press the Main Menu button.2. Select Change <strong>Pro</strong>gram, push the Selector KnobOR press Next button.3. Turn the Selector Knob until MOVE PROGRAMis displayed. Push Selector Knob OR press Nextbutton to select this feature.4. MOVE FROM: is displayed. The second line displaysa program number and name. Turn the SelectorKnob to find the program you wish to move. Push theSelector Knob OR press Next button.5. MOVE TO: is displayed. Turn the Selector Knob tofind the program number you wish to move to. If youselect a program that is all ready entered, you willwrite over the existing program. Push the SelectorKnob OR press the Next button to finish. You willbe returned to the Main Menu automatically.Erase a <strong>Pro</strong>gramThis feature allows you to erase a program from memory.The space occupied by any program erased will becomeavailable for adding a new program.<strong>Pro</strong>cedure:1. Press the Main Menu button.2. Select Change <strong>Pro</strong>gram, push the Selector KnobOR press Next button.3. Turn the Selector Knob until ERASE A PROGRAMis displayed. Push the Selector Knob OR pressNext button to select this feature.4. ERASE A PROGRAM: is displayed. Turn the SelectorKnob to find the program you wish to erase. Push theSelector Knob OR press Next button to continue.5. ERASE ??? NO is displayed. Turn the SelectorKnob to YES to erase this program or NO to abort.Push the Selector Knob OR press Next button tocontinue. You will be returned to the Main Menuautomatically.2217280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 22 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualChapter Four — Run <strong>Pro</strong>gram MenuTurn the Selector Knob until the desired program isdisplayed. If the table has not been lowered, do so now.The Run <strong>Pro</strong>gram mode allows you to run programs andto view programs as they are running.Press the Start <strong>Pro</strong>gram button to begin this program.Continue through this chapter to learn all of the displaysand features available while a program is running.Running a <strong>Pro</strong>gram – Repeat <strong>Pro</strong>gramsThe furnace features a one-button repeat feature. If aprogram needs to be repeated, simply press the SelectorKnob and the last program run will be repeated.Note: You must burn the moisture out of themuffle before firing the first time. See theNOTATION under “Change Idle Temperature” onPAGE 10.Note: This feature is disabled if any SpecialFunctions have been accessed or if the Change<strong>Pro</strong>gram feature has been used after the lastprogram was run.Loading Your Work Into the <strong>Furnace</strong>Press the down arrow key to lower the work platform.Place your work on the firing tray, press the Start <strong>Pro</strong>gramKey and it will raise automatically under program control.Features and Displays AvailableWhile a <strong>Pro</strong>gram is RunningThe following illustration shows the display when aprogram is running:>Rotating the Selector Knob while the <strong>Pro</strong>gram is runningwill display additional information in four, successivescreens:The first alternate screen:HH:MM:SSThe second alternate screen:NoTime Left:Step Left:NEXT = SKIP STEPNext = Option ChangePressing the Next button will toggle the “No” in the screenabove to “Yes”. Pressing the Next button a second timewill change the “Yes” to “No”.Note: If the Next button is pressed from thisscreen the program will skip to the nextprogram segment.2317280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 23 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualThe LED GraphThe LED graph follows the running <strong>Pro</strong>gram’s progressand provides a quick visual reference on how far theprogram has progressed.The illustrations below demonstrate the progression ofLEDs on a 1-Stage <strong>Pro</strong>gram:The illustrations below demonstrate the progression ofLEDs on a 2-Stage <strong>Pro</strong>gram:>Pre Dry segment:>Pre Dry segment:>First Rise segment:*Argon feature is only available on <strong>Pro</strong> <strong>200</strong>**Press function is only available on <strong>Pro</strong> Press <strong>200</strong>>Rate Rise segment:>First Hold segment>Hold Temp segment:>Second Rise segment:>Closed Cool segment:>Second Hold segment:>Open Cool segment:>Closed Cool segment:>Open Cool segment:2417280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 24 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualRunning a Pressing <strong>Pro</strong>gram(<strong>Pro</strong> Press <strong>200</strong> only)The <strong>Pro</strong> Press <strong>200</strong> can press into a 100, <strong>200</strong>, or 300 gram investment mold. Configure the firing tray and press insert asshow below for each size mold.1. If the muffle temperature is below the entrytemperature specified in the program, the table willraise to the closed position while the temperaturerises. If the muffle temperature is above the entrytemperature specified in the program, the tablewill remain down while the muffle cools. When theprogrammed entry temperature is reached, thefurnace will begin to beep continuously.2. After Pressing the Next button, the table will lower.Place the ring onto the firing table and press the Nextbutton. The display will read:3. The Pressing program will begin running.Note: If the Re-Press feature is disabled,(Calibration Password 315 set to “Timed Press= Yes”) then the Press time specified in thePressing <strong>Pro</strong>gram parameters will be the actualPress Time. If the Re-Press feature is enabled,(Calibration Password 315 set to “Timed Press = No”)then the Press Time will be four minutes plus theamount of Re-Press time specified.Next = Raise tableRunning a Re-Press <strong>Pro</strong>gramTo run a Re-Press <strong>Pro</strong>gram, Calibration Password number315 must be set to “Timed Press = No”Press the Special Functions Key, then rotate the Selectorknob to the “Calibration Password” prompt and press theNext key. At the password entry prompt rotate the Selectorknob until the display says “315” and press Next key.Timed Press = NoRotate the Selector Knob until the screen looks like theone above and press the Next button. This has activatedthe Re-Press mode.1. If the muffle temperature is below the entrytemperature specified in the program, the table willraise to the closed position while the temperaturerises. If the muffle temperature is above the entrytemperature specified in the program, the table willremain down while the muffle cools. When the entrytemperature is reached, the furnace will begin tobeep continuously. The display will read:Next = Raise table2. If the table is up, press the Next button, the table willlower. With the table in the down position, place thering onto the firing table and press the Next button.3. The Pressing program will begin running.4. The temperature will now rise to the final temperatureselected in the program. When the final temperatureis reached, the hold time will begin.5. When the hold time has expired the display will readas shown below. The furnace will begin the firstpress. The first press will continue for four minutes.After the first press has been completed re-pressingwill occur if password 315 is activated.(See the Calibrate Oven section of this manual forfurther information.)Pressing6. When running a re-press program the furnace willautomatically press for four minutes and then theadditional “Re-Press” time. The display will now sayRE-PRESSING and the furnace will begin to re‐pressthe work for the amount of time specified in theprogram. When the re-press time has expired, the presswill fully retract and the table will lower automatically.Re-Pressing2517280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 25 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualChapter Five — MaintenanceCleaning The <strong>Furnace</strong>Your new furnace may be cleaned by using a soft cloth andkitchen cleaners such as Fantastic ® or Formula 409 ® . The frontpanel should be cleaned with a window cleaner such as Windex ® .Never clean the display window with a dry cloth or tissue asthis will scratch the surface.Always moisten the cleaning cloth with a cleaner such asWindex ® or water.Only clean the table with Windex ® or water and a towel. Usingother cleaners will harm the anodized surface. You will encounterproblems if 409 ® or Fantastic ® is used to clean the table.CAUTION!!! NEVER OPEN THE INTERIOR OFTHE CHASSIS BEFORE FIRST REMOVING THE ACELECTRICAL POWER CORD. THERE ARE DEADLYVOLTAGES INSIDE.If, for any reason, you need to access the interior of thechassis for the purpose of minor servicing or replacementof components such as valve plungers, you must removethe chassis top plate via two screws on the rear of thechassis, then slide the chassis top plate towards the frontof the furnace, then lift it up and set it aside. DO NOTremove the six screws on the bottom of the chassis in anattempt to remove the entire chassis top assembly as thebottom portion contains various electrical connectionswhich will prevent the removal of the bottom or subjectthe electrical connections to damaging stress unless firstdisconnected from the top.NOTE: IF HAZARDOUS MATERIAL IS SPILLED ON ORINSIDE THE FURNACE, CONTACT WHIP MIX TECHNICALSUPPORT IF THERE IS ANY DOUBT AS HOW TO SAFELYREMOVE THE MATERIAL.Argon Gas Requirements and Installation (<strong>Pro</strong> <strong>200</strong> only)Enter your own program based on the manufacturer’s instructionsfor the de-contamination material you are using.USE ONLY ARGON GAS IN THE <strong>Pro</strong> <strong>200</strong> FURNACE. ATTACHINGANY FLAMMABLE OR NOXIOUS GAS TO THIS FURNACECOULD CAUSE EXPLOSION OR PERSONAL INJURY!The best source of Argon is from your local bottled gas dealer.Usually the same dealer who furnishes Oxygen can alsosupply Argon. If not, he can recommend a reliable source.There are generally three grades of Argon available and yourdealer can tell you the cost of each. Most furnace buyers usethe lower cost commercial or industrial grade of Argon.The same dealer should be able to supply a regulator for thebottled Argon. It should have a gauge showing the pressureinside the tank, and a smaller gauge showing the pressureapplied to the outside system. The smaller gauge should readno more than 120 PSI maximum applied to the furnace.The furnace requires between one and two PSI of Argongas pressure. The use of more pressure will not improve theperformance of the furnace. If you plan to use the Argongas feature of this furnace you should also purchase a lowpressureArgon post regulator kit.The low-pressure post regulator kit attaches to the regulatorsupplied by your gas supplier. Installation of the low pressureregulator is as follows:DO NOT REMOVE THE REGULATOR SUPPLIED BYYOUR BOTTLED GAS SUPPLIER. THE LOW PRESSUREREGULATOR IS IN ADDITION TO THE REGULATORSUPPLIED FOR YOUR BOTTLE.1. The regulator supplied by the bottled gas companyusually has a hose barb fitting to attach your hose.Remove this fitting.2. The low-pressure regulator kit has a 1/4 inch male pipethread fitting supplied on one end. The other end hasa hose barb fitting for the supply hose to the furnace.Attach the male pipe thread end to the regulator onthe bottle. The first gauge reads the bottle pressure,the second gauge reads the pre-regulator pressure,and the third gauge reads from 0 to 15 PSI. Do notattach the gas to the furnace yet.3. Attach one end of the supplied hose to the lowpressureregulator. Do not attach the other end to thefurnace yet.4. Turn on the gas supply to the regulators.5. Adjust the pre-regulator (supplied by your gas dealer) toaround 20 PSI.6. Pull the red locking ring on the low-pressure regulatortowards the black Selector Knob on the bottom of theregulator to release the Selector Knob. Turn the blackSelector Knob fully counterclockwise. The pressureshould be 0.7. Turn the black Selector Knob clockwise until the lowpressuregauge reads between 1.0 and 1.5 PSI.8. Push the red locking ring up towards the gauge. This willlock the pressure setting.9. Turn off the gas supply from the bottle. Be sure to turn offthe supply when the gas is not being used to avoid theloss of gas due to fitting leaks.10. Attach the hose to the Argon connector on the back ofthe furnace.The furnace is now ready to run titanium and sinteringprograms, which require Argon gas.Note: The pressure reading may jump higherthan 1.5 PSI between firing and at times duringthe purging process. This is normal. PressureMAY be checked during the inert cool step inthe firing sequence. At that time Argon is beingapplied at a constant pressure to the furnace.The gauge should read between 1 and 1.5 PSI. YouMAY adjust the regulator at this time2617280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 26 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualPurge/DecontaminationMoisture removal must be done first:When the furnace is unused for prolonged periods oftime, the muffle insulation will absorb moisture. Thismoisture can cause firing problems if not removed beforefiring porcelain. Moisture can also shorten the life of thevacuum pump. To remove moisture, change your idletemperature to 651°C/1204°F and leave your table openfor at least an hour with the firing tray in place.The purpose of a purge is to clean out cross-contaminationsin the muffle. Charcoal can be used but can shorten thelife of the thermocouple.Follow the instructions for “Adding a program” to set upyour Purge cycle using the following parameters.• Select 1 Stage• Name the program “Purge”• Dry Time: 30 seconds• Entry Temp: 400°C/752°F• Rate Rise: 50°C/90°F• Hold Temp: 1050°C/1922°F• Hold Time: 15 Minutes• Fuse Adjust: NO• Table Down: 1050°C/1922°F• Cool Time: 10 minutes• Use Vacuum: YES• Vacuum Level: 71mm/28in• Start Vacuum During: Rate Rise @ 400°C/752°F• Release Vacuum During: Hold time @ 5 MinutesIf you have any further questions regarding theseinstructions please contact TOPS at <strong>Whip</strong> <strong>Mix</strong>.Trouble Shooting GuideThe <strong>Pro</strong> <strong>200</strong> and <strong>Pro</strong> Press <strong>200</strong> furnaces offer a number ofself checks and warning messages that are designed toidentify problems. Several of these are listed below:Not Enough VacuumThis error occurs if the furnace has not achieved its targetvacuum level within 90 seconds. The program will abortautomatically. Check the vacuum level setting. If thebarometric pressure is unusual, you may have to call forfewer vacuums.Duplicate NameThis error occurs if you have entered a program name thatis identical to one all ready stored in memory. Press theNext button to continue. Enter a different name for thisprogram.Check <strong>Pro</strong>gramsThe computer has detected a corruption of the memory inthe area where programs are stored. Check all programsand correct any that have been changed.Call for assistance.Temp Cal ErrorAn error has been detected in the temperature calibration.Recalibrate the temperature to correct this problem.Vac Cal ErrorAn error has been detected in the vacuum calibration.Recalibrate the vacuum temperature to correct thisproblem.Call for assistance.Max Temp ErrorThe computer has detected a temperature reading higherthan the maximum allowed. The furnace will automaticallyshut the heating elements off. Turn the power off to resetthis error. If the error occurs again call for assistance.Thermocouple ErrorThis error occurs if the furnace detects an openthermocouple for a period of 25 seconds. The furnace willautomatically turn off the heating elements. The furnaceshould be turned off and on again to clear this error. If theerror occurs again, the thermocouple should be replaced.Call for assistance.2717280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 27 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualVacuum Test1. Press the Up arrow button to raise the table fully up.You cannot start a vacuum test until the table is fully up.2. Select the Special Functions item.3. Turn the Selector Knob to Test <strong>Furnace</strong>. Press theNext button.* Special FunctionsExport SettingsImport Settings> Test <strong>Furnace</strong>4. Turn the Selector Knob to Vacuum Test. Press theNext button. The vacuum test will automatically begin.Test <strong>Furnace</strong>> Vacuum TestPress TestMuffle TestThere will be three, numerical indicators on the screen,each has its own individual meaning.• The number to the far left is the vacuum count. Thatis the vacuum sensor reading.Vacuum Test On90 00CM 99Next=Test HoldVacuum Test On223 65CM 99Next=Test Hold• The second in the middle is the centimeters or inchesof mercury.• The third is the current condition of the table0 = moving, 99 = fully up or fully down.5. Watch the numerical indicators as they rise.6. The third value should stay at 99 and not change.Sometimes the value changes from 99 to 0 when thevacuum pump starts. This is normal and happens onsome units.7. Once the vacuum has reached 240, press the Nextbutton. This will place the test in the hold positionand allow you to watch for changes in vacuum valueand readings.The acceptable loss is 2 cm within six minutes.8. Once the test has been in hold for 6 minutes, pressthe Next button and the test will end.9. If the numbers dropped outside the acceptable lossrange, then the vacuum system has a leak and it mustbe repaired and recalibrated.FusesThe furnace contains two fuses:• On the rear, just below and to the right of the powercord, there are two 12 Amp (115 Vac) Slo-Blo or two7 Amp (220 Vac) Slo-Blo, .25 x 1.25 inch ceramicfuses.If More Help is NeededWe hope you have many years of trouble-free service fromyour furnace. If you do have problems with the furnace, orif you have questions about the furnace not covered inthe manual, contact your dealer or <strong>Whip</strong> <strong>Mix</strong> at:www.whipmix.comPhone: 800-626-5651Fax: 502-634-4512E-Mail: tops@whipmix.comBe prepared to provide the following information:1. Your name2. Your lab’s name and address3. Your lab’s phone number4. Your lab’s fax number5. <strong>Furnace</strong> model and serial number (serial numbercan be found on the rear of the furnace)6. Your question/problemWhen you call, it would be helpful if you are near thefurnace. The technician will probably ask you to run testsand report the results, or read the display while the test isrunning.2817280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 28 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations ManualReplacement PartsPart Number Description96004 Power Cord 115V96008 Power Cord 230V96001 Ceramic Plunger Rods Pkg of 296020 Investment Ringliner Pkg of 1096147 Vacuum Valve Plunger 3 way96070 Vacuum Valve Plunger 2 way96094 Lift Limit Sensor96021 Lift Belt96025 Table96309 Press Regulator with Quick disconnect96012 Press Insert Trays96013 Firing Tray with recess (Press)96015 Firing Tray Regular (<strong>Pro</strong> <strong>200</strong> & Press)96339 Encoder Assembly (Selector Knob Control)96336 Key Pad Assembly96341 Vacuum Sensor Assembly96091 Flash Drive <strong>Pro</strong> <strong>200</strong>96098 Flash Drive <strong>Pro</strong> Press <strong>200</strong>96016 Fuses (115 VAC – 12 Amp) Pkg of 296092 Fuses (250 V – 7 Amp Slo-Blo) Pkg of 2Technical SpecificationsPower Supply120 VAC ± 10% 50/60HzPower Consumption 1<strong>200</strong>W - <strong>Furnace</strong> Alone1400W - With PumpShipping Weight<strong>Pro</strong> <strong>200</strong> - 59 lbs.<strong>Pro</strong> Press <strong>200</strong> - 71 lbs.Muffle WindingsQuartz TubingMuffle Chamber3 3/4 W x 2 1/2 H x 3 3/4 DMaximum Temperature 2<strong>200</strong>°FDimensions <strong>Pro</strong> <strong>200</strong> 11" W x 16"D x 21"H<strong>Pro</strong> Press <strong>200</strong> 11"W x 16" D x 25"HNote: Other replacement parts available. ContactTOPS at 800-626-5651 for assistance. Must haveserial number on unit to identify correct part.2917280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 29 8/12/11 1:54 PM

<strong>Pro</strong> <strong>200</strong> <strong>Series</strong> <strong>Furnace</strong> Operations Manual<strong>Pro</strong> <strong>Series</strong> AccessoriesHigh-Efficiency Vacuum Pump<strong>Pro</strong>Cal3017280 <strong>Pro</strong> <strong>Series</strong> <strong>200</strong> Manual_ENG.indd 30 8/12/11 1:54 PM