link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

12 LINK <strong>59</strong> . 1 /2012<br />

PRODUCT NEWS<br />

Operating steps<br />

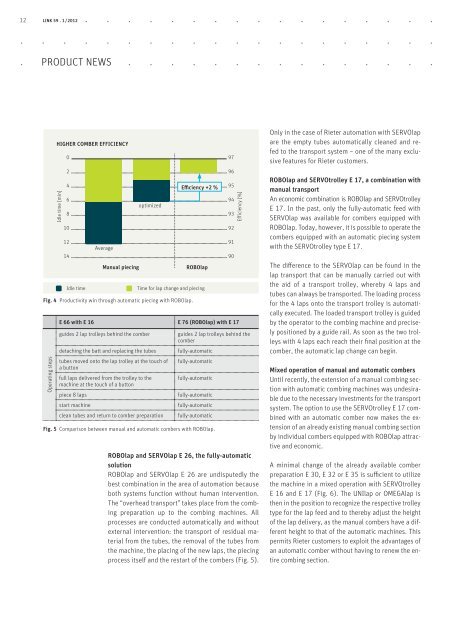

HIGHER COMBER EFFICIENCY<br />

Idle time [min]<br />

0<br />

2<br />

4<br />

6<br />

8<br />

10<br />

12<br />

14<br />

Idle time<br />

Average<br />

Manual piecing<br />

optimized<br />

Fig. 4 Productivity win through automatic piecing with ROBOlap.<br />

ROBOlap<br />

E 66 with E 16 E 76 (ROBOlap) with E 17<br />

guides 2 lap trolleys behind the comber guides 2 lap trolleys behind the<br />

comber<br />

detaching the batt and replacing the tubes fully-automatic<br />

tubes moved onto the lap trolley at the touch of<br />

a button<br />

full laps delivered from the trolley to the<br />

machine at the touch of a button<br />

Efficiency +2 %<br />

Time for lap change and piecing<br />

fully-automatic<br />

fully-automatic<br />

piece 8 laps fully-automatic<br />

start machine fully-automatic<br />

clean tubes and return to comber preparation fully-automatic<br />

Fig. 5 Comparison between manual and automatic combers with ROBOlap.<br />

ROBOlap and SERVOlap E 26, the fully-automatic<br />

solution<br />

ROBOlap and SERVOlap E 26 are undisputedly the<br />

best combination in the area of automation because<br />

both <strong>systems</strong> function without human intervention.<br />

The “overhead transport” takes place from the combing<br />

preparation up to the combing machines. All<br />

processes are conducted automatically and without<br />

external intervention: the transport of residual material<br />

from the tubes, the removal of the tubes from<br />

the machine, the placing of the new laps, the piecing<br />

process itself and the restart of the combers (Fig. 5).<br />

97<br />

96<br />

95<br />

94<br />

93<br />

92<br />

91<br />

90<br />

Efficiency [%]<br />

Only in the case of <strong>Rieter</strong> automation with SERVOlap<br />

are the empty tubes automatically cleaned and refed<br />

to the transport system – one of the many exclusive<br />

features for <strong>Rieter</strong> <strong>customer</strong>s.<br />

ROBOlap and SERVOtrolley E 17, a combination with<br />

manual transport<br />

An eco<strong>no</strong>mic combination is ROBOlap and SERVOtrolley<br />

E 17. In the past, only the fully-automatic feed with<br />

SERVOlap was available for combers equipped with<br />

ROBOlap. Today, however, it is possible to operate the<br />

combers equipped with an automatic piecing system<br />

with the SERVOtrolley type E 17.<br />

The difference to the SERVOlap can be found in the<br />

lap transport that can be manually carried out with<br />

the aid of a transport trolley, whereby 4 laps and<br />

tubes can always be transported. The loading process<br />

for the 4 laps onto the transport trolley is automatically<br />

executed. The loaded transport trolley is guided<br />

by the operator to the combing machine and precisely<br />

positioned by a guide rail. As soon as the two trolleys<br />

with 4 laps each reach their final position at the<br />

comber, the automatic lap change can begin.<br />

Mixed operation of manual and automatic combers<br />

Until recently, the extension of a manual combing section<br />

with automatic combing machines was undesirable<br />

due to the necessary investments for the transport<br />

system. The option to use the SERVOtrolley E 17 combined<br />

with an automatic comber <strong>no</strong>w makes the extension<br />

of an already existing manual combing section<br />

by individual combers equipped with ROBOlap attractive<br />

and eco<strong>no</strong>mic.<br />

A minimal change of the already available comber<br />

preparation E 30, E 32 or E 35 is sufficient to utilize<br />

the machine in a mixed operation with SERVOtrolley<br />

E 16 and E 17 (Fig. 6). The UNIlap or OMEGAlap is<br />

then in the position to recognize the respective trolley<br />

type for the lap feed and to thereby adjust the height<br />

of the lap delivery, as the manual combers have a different<br />

height to that of the automatic machines. This<br />

permits <strong>Rieter</strong> <strong>customer</strong>s to exploit the advantages of<br />

an automatic comber without having to renew the entire<br />

combing section.