link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

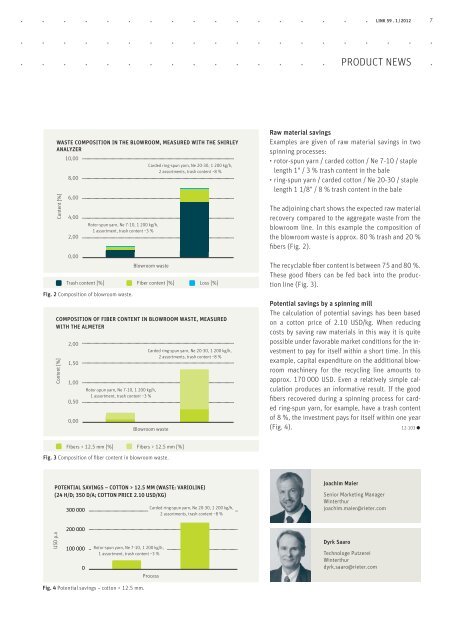

WASTE COMPOSITION IN THE BLOWROOM, MEASURED WITH THE SHIRLEY<br />

ANALYZER<br />

Content [%]<br />

Trash content [%]<br />

300 000<br />

200 000<br />

100 000<br />

0<br />

Rotor-<strong>spun</strong> <strong>yarn</strong>, Ne 7-10, 1 200 kg/h,<br />

1 assortment, trash content ~3 %<br />

Fig. 2 Composition of blowroom waste.<br />

Carded ring-<strong>spun</strong> <strong>yarn</strong>, Ne 20-30, 1 200 kg/h,<br />

2 assortments, trash content ~8 %<br />

Blowroom waste<br />

Fiber content [%] Loss [%]<br />

COMPOSITION OF FIBER CONTENT IN BLOWROOM WASTE, MEASURED<br />

WITH THE ALMETER<br />

Content [%]<br />

Rotor-<strong>spun</strong> <strong>yarn</strong>, Ne 7-10, 1 200 kg/h,<br />

1 assortment, trash content ~3 %<br />

Fibers < 12.5 mm [%]<br />

Carded ring-<strong>spun</strong> <strong>yarn</strong>, Ne 20-30, 1 200 kg/h,<br />

2 assortments, trash content ~8 %<br />

Blowroom waste<br />

Fibers > 12.5 mm [%]<br />

Fig. 3 Composition of fiber content in blowroom waste.<br />

POTENTIAL SAVINGS – COTTON > 12.5 MM (WASTE: VARIOLINE)<br />

(24 H/D; 350 D/A; COTTON PRICE 2.10 USD/KG)<br />

USD p.a<br />

10,00<br />

8,00<br />

6,00<br />

4,00<br />

2,00<br />

0,00<br />

2,00<br />

1,50<br />

1,00<br />

0,50<br />

0,00<br />

Rotor-<strong>spun</strong> <strong>yarn</strong>, Ne 7-10, 1 200 kg/h,<br />

1 assortment, trash content ~3 %<br />

Fig. 4 Potential savings – cotton > 12.5 mm.<br />

Carded ring-<strong>spun</strong> <strong>yarn</strong>, Ne 20-30, 1 200 kg/h,<br />

2 assortments, trash content ~8 %<br />

Process<br />

Joachim Maier<br />

Dyrk Saaro<br />

LINK <strong>59</strong> . 1 /2012<br />

PRODUCT NEWS<br />

Raw material savings<br />

Examples are given of raw material savings in two<br />

spinning processes:<br />

• rotor-<strong>spun</strong> <strong>yarn</strong> / carded cotton / Ne 7-10 / staple<br />

length 1" / 3 % trash content in the bale<br />

• ring-<strong>spun</strong> <strong>yarn</strong> / carded cotton / Ne 20-30 / staple<br />

length 1 1/8" / 8 % trash content in the bale<br />

The adjoining chart shows the expected raw material<br />

recovery compared to the aggregate waste from the<br />

blowroom line. In this example the composition of<br />

the blowroom waste is approx. 80 % trash and 20 %<br />

fibers (Fig. 2).<br />

The recyclable fiber content is between 75 and 80 %.<br />

These good fibers can be fed back into the production<br />

line (Fig. 3).<br />

Potential savings by a spinning mill<br />

The calculation of potential savings has been based<br />

on a cotton price of 2.10 USD/kg. When reducing<br />

costs by saving raw materials in this way it is quite<br />

possible under favorable market conditions for the investment<br />

to pay for itself within a short time. In this<br />

example, capital expenditure on the additional blowroom<br />

machinery for the recycling line amounts to<br />

approx. 170 000 USD. Even a relatively simple calculation<br />

produces an informative result. If the good<br />

fibers recovered during a spinning process for carded<br />

ring-<strong>spun</strong> <strong>yarn</strong>, for example, have a trash content<br />

of 8 %, the investment pays for itself within one year<br />

(Fig. 4). 12-103 •<br />

Senior Marketing Manager<br />

Winterthur<br />

joachim.maier@rieter.com<br />

Tech<strong>no</strong>loge Putzerei<br />

Winterthur<br />

dyrk.saaro@rieter.com<br />

7