link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

22 LINK <strong>59</strong> . 1 /2012<br />

TECHNOLOGY<br />

Processing of Indian Cotton<br />

How can 1 1/16" cotton with a high short fiber content best be processed?<br />

Tests on the <strong>Rieter</strong> rotor spinning and ring spinning <strong>systems</strong> provide<br />

indications. The possibilities and the potential of processing 100 %<br />

cotton on a rotor spinning machine are today in the Asian countries still<br />

far from being exhausted.<br />

You can obtain further<br />

details on this test in<br />

the 20-page special<br />

print “Processing<br />

Indian Raw Cotton”<br />

which you can download<br />

in Internet using<br />

the printed code.<br />

http://bit.ly/ItN4Lm<br />

Fig. 1 Areas of application<br />

of the spinning<br />

<strong>systems</strong>.<br />

[1 0 0 0 0 0 0 tons]<br />

(mm)<br />

(inch)<br />

RANGE OF APPLICATION OF THE SPINNING SYSTEMS FOR 100 % COTTON<br />

5 . 0<br />

4 . 5<br />

4 . 0<br />

3 . 5<br />

3 . 0<br />

2 . 5<br />

2 . 0<br />

1 . 5<br />

1 . 0<br />

0 . 5<br />

0<br />

2 3 . 0-2 5 . 4 2 6 . 1 9 2 6 . 9 9 2 7 . 7 8 2 8 . 5 8 2 9 . 3 7 3 0 . 1 6 3 0 . 9 6 3 1 . 7 5 3 2 . 5 4 3 3 . 3 4 3 4 . 1 3 3 4 . 9 3 3 5 . 7 -4 4 . 4 1<br />

2 9 /3 2 -1 1 1 /3 2 1 1 /1 6 1 3 /3 2 1 1 /8 1 5 /3 2 1 3 /1 6 1 7 /3 2 1 1 /4 1 9 /3 2 1 5 /1 6 1 1 1 /3 2 1 3 /8 1 3 /3 2 -1 3 /4<br />

short<br />

AFIS Autojet; commercial staple; UQL (w) (mm)<br />

In the processing of 100 % cotton with the rotor<br />

spinning system, the appropriate field of application<br />

based on eco<strong>no</strong>mic and quality aspects lies in a staple<br />

length range from 1" to 1 1/8" cotton. According<br />

to the short fiber percentage and trash content of the<br />

cotton, the rotor tech<strong>no</strong>logy is often the only option<br />

to produce <strong>yarn</strong> eco<strong>no</strong>mically – and simultaneously<br />

in the quality demanded. Depending on the staple<br />

length of the cotton, the areas of application for the<br />

various end spinning processes can thereby be allocated<br />

(Fig. 1).<br />

Up to 2010 already 7.8 million rotor spinning units<br />

worldwide have been installed. In comparison to<br />

the installed ring spindles, this number is small.<br />

As, however, the productivity of a rotor unit compared<br />

to a ring spinning unit is higher by the factor<br />

Ring spinning<br />

Rotor spinning Air-jet spinning<br />

medium long extra long<br />

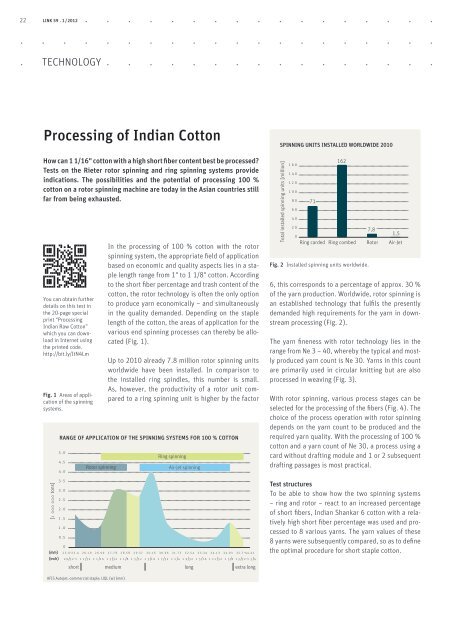

SPINNING UNITS INSTALLED WORLDWIDE 2010<br />

Total installed spinning units [million]<br />

1 6 0<br />

1 4 0<br />

1 2 0<br />

1 0 0<br />

8 0<br />

6 0<br />

4 0<br />

2 0<br />

0<br />

71<br />

162<br />

Fig. 2 Installed spinning units worldwide.<br />

7,8<br />

1,5<br />

Ring carded Ring combed Rotor Air-Jet<br />

6, this corresponds to a percentage of approx. 30 %<br />

of the <strong>yarn</strong> production. Worldwide, rotor spinning is<br />

an established tech<strong>no</strong>logy that fulfils the presently<br />

demanded high requirements for the <strong>yarn</strong> in downstream<br />

processing (Fig. 2).<br />

The <strong>yarn</strong> fineness with rotor tech<strong>no</strong>logy lies in the<br />

range from Ne 3 – 40, whereby the typical and mostly<br />

produced <strong>yarn</strong> count is Ne 30. Yarns in this count<br />

are primarily used in circular knitting but are also<br />

processed in weaving (Fig. 3).<br />

With rotor spinning, various process stages can be<br />

selected for the processing of the fibers (Fig. 4). The<br />

choice of the process operation with rotor spinning<br />

depends on the <strong>yarn</strong> count to be produced and the<br />

required <strong>yarn</strong> quality. With the processing of 100 %<br />

cotton and a <strong>yarn</strong> count of Ne 30, a process using a<br />

card without drafting module and 1 or 2 subsequent<br />

drafting passages is most practical.<br />

Test structures<br />

To be able to show how the two spinning <strong>systems</strong><br />

– ring and rotor – react to an increased percentage<br />

of short fibers, Indian Shankar 6 cotton with a relatively<br />

high short fiber percentage was used and processed<br />

to 8 various <strong>yarn</strong>s. The <strong>yarn</strong> values of these<br />

8 <strong>yarn</strong>s were subsequently compared, so as to define<br />

the optimal procedure for short staple cotton.