link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

24 LINK <strong>59</strong> . 1 /2012<br />

TECHNOLOGY<br />

Mean fiber length (n) [mm]<br />

Fig. 6<br />

Fig. 7<br />

Number of imperfections<br />

Fig. 8<br />

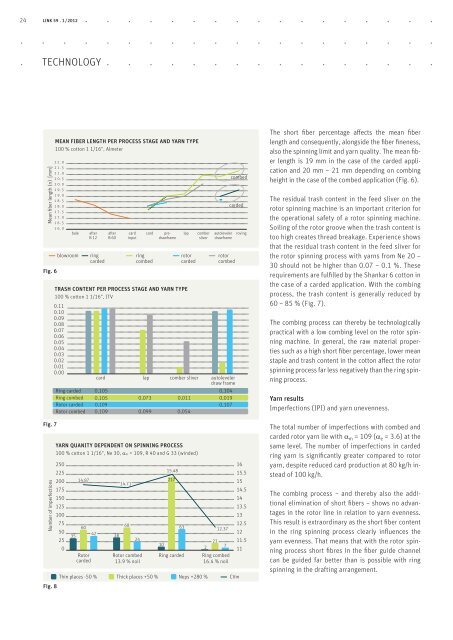

MEAN FIBER LENGTH PER PROCESS STAGE AND YARN TYPE<br />

100 % cotton 1 1/16", Almeter<br />

2 2 . 0<br />

2 1 . 5<br />

2 1 . 0<br />

2 0 . 5<br />

2 0 . 0<br />

1 9 . 5<br />

1 9 . 0<br />

1 8 . 5<br />

1 8 . 0<br />

1 7 . 5<br />

1 7 . 0<br />

1 6 . 5<br />

1 6 . 0<br />

0.11<br />

0.10<br />

0.09<br />

0.08<br />

0.07<br />

0.06<br />

0.05<br />

0.04<br />

0.03<br />

0.02<br />

0.01<br />

0.00<br />

250<br />

225<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

0<br />

bale after<br />

B 12<br />

blowroom ring<br />

carded<br />

35<br />

14.87<br />

60<br />

card lap comber sliver autoleveler<br />

draw frame<br />

0,105<br />

0,104<br />

0,105 0,073 0,011 0,019<br />

0,109<br />

0,107<br />

0,109<br />

0,099 0,054<br />

42<br />

after<br />

B 60<br />

38<br />

14.71<br />

card<br />

input<br />

68<br />

ring<br />

combed<br />

TRASH CONTENT PER PROCESS STAGE AND YARN TYPE<br />

100 % cotton 1 1/16", ITV<br />

Ring carded<br />

Ring combed<br />

Rotor carded<br />

Rotor combed<br />

24<br />

card pre- lap comber autoleveler roving<br />

drawframe<br />

sliver drawframe<br />

10<br />

15.48<br />

217<br />

rotor<br />

carded<br />

YARN QUANITY DEPENDENT ON SPINNING PROCESS<br />

100 % cotton 1 1/16", Ne 30, αm = 109, R 40 and G 33 (winded)<br />

Rotor<br />

carded<br />

Rotor combed<br />

13.9 % <strong>no</strong>il<br />

63<br />

Ring carded<br />

Thin places -50 % Thick places +50 % Neps +280 %<br />

2<br />

21<br />

rotor<br />

combed<br />

12.37<br />

7<br />

Ring combed<br />

16.4 % <strong>no</strong>il<br />

combed<br />

carded<br />

CVm<br />

16<br />

15.5<br />

15<br />

14.5<br />

14<br />

13.5<br />

13<br />

12.5<br />

12<br />

11.5<br />

11<br />

The short fiber percentage affects the mean fiber<br />

length and consequently, alongside the fiber fineness,<br />

also the spinning limit and <strong>yarn</strong> quality. The mean fiber<br />

length is 19 mm in the case of the carded application<br />

and 20 mm – 21 mm depending on combing<br />

height in the case of the combed application (Fig. 6).<br />

The residual trash content in the feed sliver on the<br />

rotor spinning machine is an important criterion for<br />

the operational safety of a rotor spinning machine.<br />

Soiling of the rotor groove when the trash content is<br />

too high creates thread breakage. Experience shows<br />

that the residual trash content in the feed sliver for<br />

the rotor spinning process with <strong>yarn</strong>s from Ne 20 –<br />

30 should <strong>no</strong>t be higher than 0.07 – 0.1 %. These<br />

requirements are fulfilled by the Shankar 6 cotton in<br />

the case of a carded application. With the combing<br />

process, the trash content is generally reduced by<br />

60 – 85 % (Fig. 7).<br />

The combing process can thereby be tech<strong>no</strong>logically<br />

practical with a low combing level on the rotor spinning<br />

machine. In general, the raw material properties<br />

such as a high short fiber percentage, lower mean<br />

staple and trash content in the cotton affect the rotor<br />

spinning process far less negatively than the ring spinning<br />

process.<br />

Yarn results<br />

Imperfections (IPI) and <strong>yarn</strong> unevenness.<br />

The total number of imperfections with combed and<br />

carded rotor <strong>yarn</strong> lie with α m = 109 (α e = 3.6) at the<br />

same level. The number of imperfections in carded<br />

ring <strong>yarn</strong> is significantly greater compared to rotor<br />

<strong>yarn</strong>, despite reduced card production at 80 kg/h instead<br />

of 100 kg/h.<br />

The combing process – and thereby also the additional<br />

elimination of short fibers – shows <strong>no</strong> advantages<br />

in the rotor line in relation to <strong>yarn</strong> evenness.<br />

This result is extraordinary as the short fiber content<br />

in the ring spinning process clearly influences the<br />

<strong>yarn</strong> evenness. That means that with the rotor spinning<br />

process short fibres in the fiber guide channel<br />

can be guided far better than is possible with ring<br />

spinning in the drafting arrangement.