link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

link no. 59 customer magazine spun yarn systems - Rieter

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6 LINK <strong>59</strong> . 1 /2012<br />

PRODUCT NEWS<br />

Recovering good fibers from<br />

blowroom waste<br />

Good fibers can easily be recovered from blowroom waste with the<br />

<strong>Rieter</strong> Recycling Line. These raw material savings make a significant<br />

contribution to a spinning mill’s operating profits.<br />

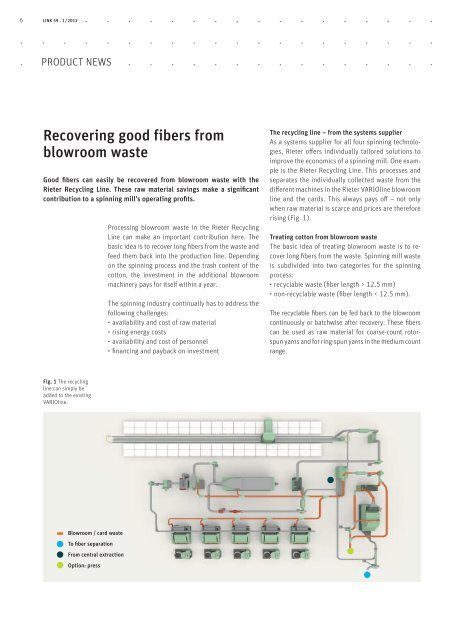

Fig. 1 The recycling<br />

line can simply be<br />

added to the existing<br />

VARIOline.<br />

Blowroom / card waste<br />

To fiber separation<br />

From central extraction<br />

Option: press<br />

Processing blowroom waste in the <strong>Rieter</strong> Recycling<br />

Line can make an important contribution here. The<br />

basic idea is to recover long fibers from the waste and<br />

feed them back into the production line. Depending<br />

on the spinning process and the trash content of the<br />

cotton, the investment in the additional blowroom<br />

machinery pays for itself within a year.<br />

The spinning industry continually has to address the<br />

following challenges:<br />

• availability and cost of raw material<br />

• rising energy costs<br />

• availability and cost of personnel<br />

• financing and payback on investment<br />

The recycling line – from the <strong>systems</strong> supplier<br />

As a <strong>systems</strong> supplier for all four spinning tech<strong>no</strong>logies,<br />

<strong>Rieter</strong> offers individually tailored solutions to<br />

improve the eco<strong>no</strong>mics of a spinning mill. One example<br />

is the <strong>Rieter</strong> Recycling Line. This processes and<br />

separates the individually collected waste from the<br />

different machines in the <strong>Rieter</strong> VARIOline blowroom<br />

line and the cards. This always pays off – <strong>no</strong>t only<br />

when raw material is scarce and prices are therefore<br />

rising (Fig. 1).<br />

Treating cotton from blowroom waste<br />

The basic idea of treating blowroom waste is to recover<br />

long fibers from the waste. Spinning mill waste<br />

is subdivided into two categories for the spinning<br />

process:<br />

• recyclable waste (fiber length > 12.5 mm)<br />

• <strong>no</strong>n-recyclable waste (fiber length < 12.5 mm).<br />

The recyclable fibers can be fed back to the blowroom<br />

continuously or batchwise after recovery. These fibers<br />

can be used as raw material for coarse-count rotor<strong>spun</strong><br />

<strong>yarn</strong>s and for ring-<strong>spun</strong> <strong>yarn</strong>s in the medium count<br />

range.