TotalPac®2 Dry - FIREFLEX SYSTEMS

TotalPac®2 Dry - FIREFLEX SYSTEMS

TotalPac®2 Dry - FIREFLEX SYSTEMS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

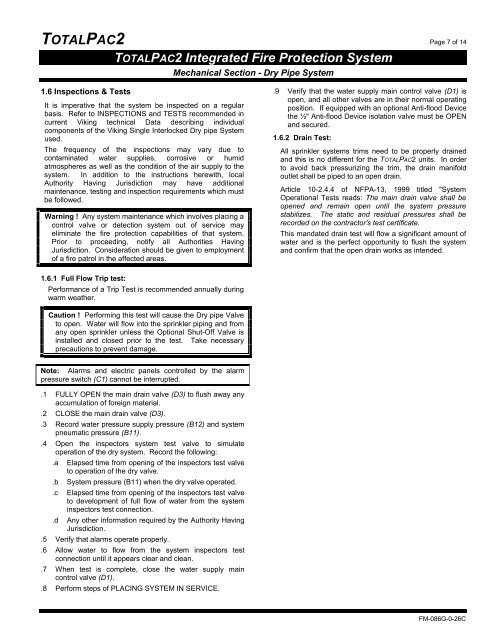

TOTALPAC2 Page 7 of 14TOTALPAC2 Integrated Fire Protection SystemMechanical Section - <strong>Dry</strong> Pipe System1.6 Inspections & TestsIt is imperative that the system be inspected on a regularbasis. Refer to INSPECTIONS and TESTS recommended incurrent Viking technical Data describing individualcomponents of the Viking Single Interlocked <strong>Dry</strong> pipe Systemused.The frequency of the inspections may vary due tocontaminated water supplies, corrosive or humidatmospheres as well as the condition of the air supply to thesystem. In addition to the instructions herewith, localAuthority Having Jurisdiction may have additionalmaintenance, testing and inspection requirements which mustbe followed.Warning ! Any system maintenance which involves placing acontrol valve or detection system out of service mayeliminate the fire protection capabilities of that system.Prior to proceeding, notify all Authorities HavingJurisdiction. Consideration should be given to employmentof a fire patrol in the affected areas..9 Verify that the water supply main control valve (D1) isopen, and all other valves are in their normal operatingposition. If equipped with an optional Anti-flood Devicethe ½" Anti-flood Device isolation valve must be OPENand secured.1.6.2 Drain Test:All sprinkler systems trims need to be properly drainedand this is no different for the TOTALPAC2 units. In orderto avoid back pressurizing the trim, the drain manifoldoutlet shall be piped to an open drain.Article 10-2.4.4 of NFPA-13, 1999 titled "SystemOperational Tests reads: The main drain valve shall beopened and remain open until the system pressurestabilizes. The static and residual pressures shall berecorded on the contractor's test certificate.This mandated drain test will flow a significant amount ofwater and is the perfect opportunity to flush the systemand confirm that the open drain works as intended.1.6.1 Full Flow Trip test:Performance of a Trip Test is recommended annually duringwarm weather.Caution ! Performing this test will cause the <strong>Dry</strong> pipe Valveto open. Water will flow into the sprinkler piping and fromany open sprinkler unless the Optional Shut-Off Valve isinstalled and closed prior to the test. Take necessaryprecautions to prevent damage.Note: Alarms and electric panels controlled by the alarmpressure switch (C1) cannot be interrupted..1 FULLY OPEN the main drain valve (D3) to flush away anyaccumulation of foreign material..2 CLOSE the main drain valve (D3)..3 Record water pressure supply pressure (B12) and systempneumatic pressure (B11)..4 Open the inspectors system test valve to simulateoperation of the dry system. Record the following:.a Elapsed time from opening of the inspectors test valveto operation of the dry valve..b System pressure (B11) when the dry valve operated..c Elapsed time from opening of the inspectors test valveto development of full flow of water from the systeminspectors test connection..d Any other information required by the Authority HavingJurisdiction..5 Verify that alarms operate properly..6 Allow water to flow from the system inspectors testconnection until it appears clear and clean..7 When test is complete, close the water supply maincontrol valve (D1)..8 Perform steps of PLACING SYSTEM IN SERVICE.FM-086G-0-26C