Read the Registration Document - Guerbet

Read the Registration Document - Guerbet

Read the Registration Document - Guerbet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

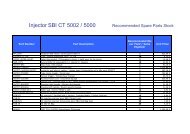

4) Manufacturing activity, investments and R&Da) Manufacturing activity, logistics and investments<strong>Guerbet</strong> manages <strong>the</strong> complete production and manufacturing cycle through its four production sites and itsnetwork of subcontractors.Three of <strong>Guerbet</strong>'s four production sites- are located in France:o A fine chemical facility located in Marans, Nor<strong>the</strong>ast of La Rochelle (CharenteMaritime), specialised in <strong>the</strong> syn<strong>the</strong>sis and production of active ingredients andchemical intermediates. In addition, Simafex has developed toll manufacturing servicesfor pharmaceutical companies and acquired specific expertise in process extrapolation,o The Lanester site (Morbihan) manufacturers active ingredients for <strong>the</strong> X-ray line,o The Aulnay-sous-Bois site (Seine-Saint-Denis) manufacturers finishedpharmaceutical products,- Plus one pharmaceutical production plant in Brazil based in Rio de Janeiro.<strong>Guerbet</strong> also has three distribution centres located in Europe, Asia and South America. Our logisticsexpertise contributes to optimising costs and guarantees that delivery deadlines are met while maintaining<strong>the</strong> quality standards of our products. The Gonesse platform located near <strong>the</strong> Aulnay-sous-Bois sitehandles our product ranges destined for Europe, <strong>the</strong> US, Africa and <strong>the</strong> Middle East. Our Hong Kong centremanages distribution for <strong>the</strong> entire Asia region where proximity to local markets is essential. Finally, ourBrazilian subsidiary has a logistics department and supplies all of South America. Measures have beentaken to complete our logistics capabilities in <strong>the</strong> US to prepare for Dotarem's launch.For several years, <strong>Guerbet</strong> has been preparing for <strong>the</strong> future by investing in its industrial base:- Chemical manufacturing for intermediates and active ingredients;- Production of finished pharmaceutical products in <strong>the</strong> form of sterile injectable solutions (vials andbags).These investments are part of an ambitious programme for modernising <strong>the</strong> industrial sites to increaseproduction capacity and competitiveness by securing supplies, improving productivity and <strong>the</strong> productiontime cycle and reducing production costs. Fur<strong>the</strong>rmore, significant efforts have been taken to improve <strong>the</strong>environmental performance of manufacturing sites. Commitment to quality, respecting internationalmanufacturing standards reinforced safety and respecting <strong>the</strong> environment are integral parts of <strong>the</strong> Group'sindustrial strategy.At Marans, after <strong>the</strong> production line for <strong>the</strong> active ingredient of Lipiodol® was fully renovated, productioncapacity for chemicals in <strong>the</strong> MRI sector were increased significantly in order to meet growing demand forDotarem®, streng<strong>the</strong>ned by <strong>the</strong> preparation for its launch in <strong>the</strong> US. Investments at <strong>the</strong> Marans site alsoconcerned completion of <strong>the</strong> first phases for improving environmental performance and streng<strong>the</strong>ning fireprotection and prevention systems.At Lanester, capacity investments were completed for Xenetix® though important investments have beenundertaken to improve <strong>the</strong> environmental footprint involving notably <strong>the</strong> recycling of iodine, <strong>the</strong> treatment ofeffluents and <strong>the</strong> management and prevention of industrial risks.At Aulnay-sous-Bois, <strong>the</strong> Group has invested in a new filling unit for <strong>the</strong> manufacture of injectablesolutions in <strong>the</strong> form of vials and bags that is in <strong>the</strong> process of being completed. Buildings and <strong>the</strong>installation of utilities have been completed and <strong>the</strong> first validations of <strong>the</strong> vial and bag filling lines initiallyscheduled for end of 2012 have been moved ahead to 2013. This investment responds to demand forincreasing production capacity, improving productivity and meeting international standards of quality for <strong>the</strong>manufacture of injectable pharmaceutical products.At <strong>the</strong> Rio de Janeiro plant, investments for <strong>the</strong> renewal of <strong>the</strong> filling line are in progress and will becommissioned at <strong>the</strong> end of 2013. They involve mainly <strong>the</strong> installation of a new cleaning machine and anew bag filling line.Overall, between 2005 and 2012, capital expenditures for <strong>Guerbet</strong>'s French manufacturing sites havetotalled €186 million.14