- Page 1 and 2:

Value through InnovationCorporate M

- Page 3 and 4:

our businesses66 [ prescription med

- Page 7:

value through innovationperspective

- Page 10 and 11:

56° 40' 59" N, 5° 6' 14" Wglencoe

- Page 12 and 13:

56° 40' 59" N, 5° 6' 14" Wglencoe

- Page 14 and 15:

PERSPECTIVES FORSOCIETYIn all our a

- Page 16 and 17:

50 NATIONSPeople from around 50 nat

- Page 18 and 19:

“RLDP journey: a great learning o

- Page 20 and 21:

SHONA MCDONALD, SHONAQUIP[ south af

- Page 22 and 23:

SEHNAZ LAYIKEL, RUSIHAK[ turkey ]he

- Page 24 and 25:

Thalita Guimaraes joins the “Boeh

- Page 26 and 27:

When handling chemicals, employees

- Page 28 and 29:

11 With its own wastewater treatmen

- Page 30 and 31:

21 Dr Carolyn R. Bertozzi received

- Page 32 and 33:

PERSPECTIVES FOR THE SOCIETYOF TOMO

- Page 34 and 35:

The opening ceremony of IMB:Interac

- Page 36 and 37:

CIRCUIT MECHANICS OF EMOTIONSUnders

- Page 38 and 39:

BIBERACH UNIVERSITY OF APPLIEDSCIEN

- Page 40 and 41:

22° 41' 0" S, 14° 32' 0" Eswakopm

- Page 42 and 43:

22° 41' 0" S, 14° 32' 0" Eswakopm

- Page 44 and 45:

PERSPECTIVES FORMEDICAL INNOVATIONB

- Page 46 and 47:

RESEARCH PARTNERSHIPS WITHACADEMIA

- Page 48 and 49:

collaborate innovate accelerateTRAN

- Page 50 and 51: GLORIA-AF®Registry programme for p

- Page 52 and 53: BOEHRINGER INGELHEIM ONCOLOGY FRANC

- Page 54 and 55: AFATINIB BLOCKS THE ERBB RECEPTORSE

- Page 56 and 57: HEPTATIS C VIRUS (HCV) INFECTIONHCV

- Page 58 and 59: 1viral entryrnareleasernatranslated

- Page 60 and 61: 12THE MAIN COMPLICATIONS OF DIABETE

- Page 62 and 63: ASTHMAAsthma is a chronic disease c

- Page 64 and 65: THERAPEUTIC AREA (TA) REVIEW CORE T

- Page 66 and 67: 6° 59' 15" N, 125° 16' 15" Eapo,

- Page 68 and 69: icardo f. solitariadistrict manager

- Page 70 and 71: PERSPECTIVES FORBETTER HEALTHBoehri

- Page 72 and 73: “My photo shows Frau Röhrigfrom

- Page 74 and 75: OUR CARDIOVASCULAR PORTFOLIOaggreno

- Page 76 and 77: HOW ATRIAL FIBRILLATION (AF)LEADS T

- Page 78 and 79: FINDING THE RIGHT MOLECULE“Findin

- Page 80 and 81: PATIENTS AT CARDIOVASCULAR RISKMost

- Page 82 and 83: TRAJENTA® / TRADJENTA®trajenta®

- Page 84 and 85: WORLD DIABETES DAYWorld Diabetes Da

- Page 86 and 87: SPIRIVA®: 10 YEARS AND MORE OF CLI

- Page 88 and 89: BEHAVIOUR CHANGE INTYPE 2 DIABETEST

- Page 90 and 91: Rapid progress in global healthcare

- Page 92 and 93: KEY GOALS OF GLOBAL BUSINESS SERVIC

- Page 94 and 95: “The perspectives that open upune

- Page 96 and 97: OUR GLOBAL SWITCH TEAMThe Switch un

- Page 98 and 99: “For me, the photo shows thatthe

- Page 102 and 103: “The hard-working beessuccessfull

- Page 104 and 105: “There are many things and experi

- Page 106 and 107: OUR GLOBAL SCIENTIFIC NET WORKIN AN

- Page 108 and 109: 2 31 Scientists in Hannover working

- Page 110 and 111: “Living and working on a differen

- Page 112 and 113: 1 Phoenix, the first captive-bredOr

- Page 114 and 115: 55° 21' 0" N, 131° 40' 24" Wketch

- Page 116 and 117: scott zhangstrategic effectiveness

- Page 118 and 119: PERSPECTIVES FORQUALITY IN OPERATIO

- Page 120 and 121: With the quality risk management sy

- Page 122 and 123: In order to ensure patient safety,

- Page 124 and 125: 37° 34' 48" N, 14° 16' 34" Esicil

- Page 126 and 127: 37° 34' 48" N, 14° 16' 34" Esicil

- Page 128 and 129: PERSPECTIVES FORESTABLISHED MARKETS

- Page 130 and 131: Spain is one of the countries struc

- Page 132 and 133: 21 View of Athens.2 Production site

- Page 134 and 135: 1 View of San Francisco, the leadin

- Page 136 and 137: 211 View of Tokyo with Japan’s hi

- Page 138 and 139: IF YOU HAVE ANY QUERIES OR COMMENTS

- Page 140 and 141: Value through InnovationBusiness Ye

- Page 142 and 143: product portfolio70 [ branded presc

- Page 144 and 145: usiness year 2012our companyOUR COM

- Page 146 and 147: usiness year 2012the shareholders

- Page 148 and 149: usiness year 2012the shareholders

- Page 150 and 151:

usiness year 2012 key aspects 2012S

- Page 152 and 153:

usiness year 2012 key aspects 2012F

- Page 154 and 155:

usiness year 2012 key aspects 2012B

- Page 156 and 157:

usiness year 2012corporate bodiesCO

- Page 158 and 159:

usiness year 2012group management r

- Page 160 and 161:

usiness year 2012group management r

- Page 162 and 163:

usiness year 2012group management r

- Page 164 and 165:

usiness year 2012group management r

- Page 166 and 167:

usiness year 2012group management r

- Page 168 and 169:

usiness year 2012group management r

- Page 170 and 171:

usiness year 2012group management r

- Page 172 and 173:

usiness year 2012group management r

- Page 174 and 175:

usiness year 2012group management r

- Page 176 and 177:

usiness year 2012group management r

- Page 178 and 179:

usiness year 2012consolidated finan

- Page 180 and 181:

usiness year 2012consolidated finan

- Page 182 and 183:

usiness year 2012consolidated finan

- Page 184 and 185:

usiness year 2012consolidated finan

- Page 186 and 187:

usiness year 2012consolidated finan

- Page 188 and 189:

usiness year 2012consolidated finan

- Page 190 and 191:

usiness year 2012consolidated finan

- Page 192 and 193:

usiness year 2012consolidated finan

- Page 194 and 195:

usiness year 2012consolidated finan

- Page 196 and 197:

usiness year 2012consolidated finan

- Page 198 and 199:

usiness year 2012consolidated finan

- Page 200 and 201:

usiness year 2012consolidated finan

- Page 202 and 203:

usiness year 2012consolidated finan

- Page 204 and 205:

usiness year 2012consolidated finan

- Page 206 and 207:

usiness year 2012auditor’s report

- Page 208 and 209:

product portfolioa selection2012PRO

- Page 210 and 211:

product portfoliobranded prescripti

- Page 212 and 213:

product portfoliobranded prescripti

- Page 214 and 215:

product portfoliobranded prescripti

- Page 216 and 217:

product portfoliobranded prescripti

- Page 218 and 219:

product portfoliobranded prescripti

- Page 220 and 221:

product portfolioconsumer health ca

- Page 222 and 223:

product portfolioconsumer health ca

- Page 224 and 225:

product portfolioconsumer health ca

- Page 226 and 227:

product portfolioconsumer health ca

- Page 228 and 229:

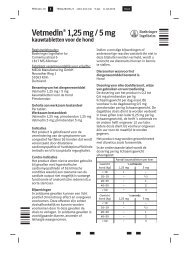

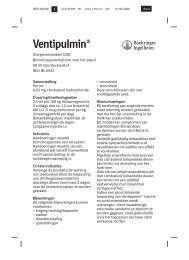

product portfolioanimal healthIndic

- Page 230 and 231:

product portfolioanimal healthIndic

- Page 232 and 233:

product portfolioanimal healthIndic

- Page 234 and 235:

product portfolioanimal healthIndic

- Page 236 and 237:

usiness year 2012financial data2006

- Page 238:

www.boehringer-ingelheim.comannualr