Lebanon Post-Conflict Environmental Assessment - UNEP

Lebanon Post-Conflict Environmental Assessment - UNEP

Lebanon Post-Conflict Environmental Assessment - UNEP

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

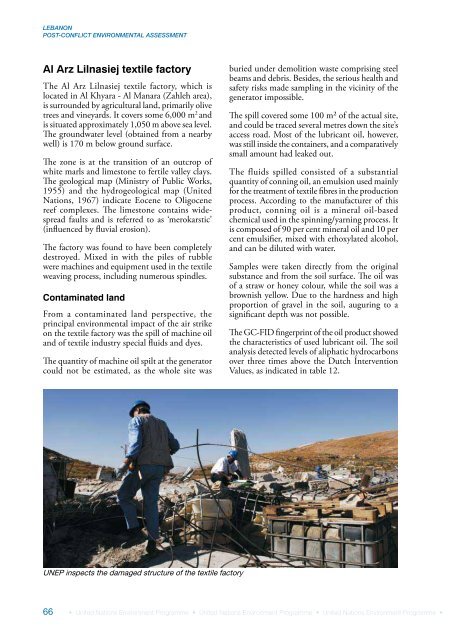

LEBANONPOST-CONFLICT ENVIRONMENTAL ASSESSMENTAl Arz Lilnasiej textile factoryThe Al Arz Lilnasiej textile factory, which islocated in Al Khyara - Al Manara (Zahleh area),is surrounded by agricultural land, primarily olivetrees and vineyards. It covers some 6,000 m 2 andis situated approximately 1,050 m above sea level.The groundwater level (obtained from a nearbywell) is 170 m below ground surface.The zone is at the transition of an outcrop ofwhite marls and limestone to fertile valley clays.The geological map (Ministry of Public Works,1955) and the hydrogeological map (UnitedNations, 1967) indicate Eocene to Oligocenereef complexes. The limestone contains widespreadfaults and is referred to as ‘merokarstic’(influenced by fluvial erosion).The factory was found to have been completelydestroyed. Mixed in with the piles of rubblewere machines and equipment used in the textileweaving process, including numerous spindles.Contaminated landFrom a contaminated land perspective, theprincipal environmental impact of the air strikeon the textile factory was the spill of machine oiland of textile industry special fluids and dyes.The quantity of machine oil spilt at the generatorcould not be estimated, as the whole site wasburied under demolition waste comprising steelbeams and debris. Besides, the serious health andsafety risks made sampling in the vicinity of thegenerator impossible.The spill covered some 100 m² of the actual site,and could be traced several metres down the site’saccess road. Most of the lubricant oil, however,was still inside the containers, and a comparativelysmall amount had leaked out.The fluids spilled consisted of a substantialquantity of conning oil, an emulsion used mainlyfor the treatment of textile fibres in the productionprocess. According to the manufacturer of thisproduct, conning oil is a mineral oil-basedchemical used in the spinning/yarning process. Itis composed of 90 per cent mineral oil and 10 percent emulsifier, mixed with ethoxylated alcohol,and can be diluted with water.Samples were taken directly from the originalsubstance and from the soil surface. The oil wasof a straw or honey colour, while the soil was abrownish yellow. Due to the hardness and highproportion of gravel in the soil, auguring to asignificant depth was not possible.The GC-FID fingerprint of the oil product showedthe characteristics of used lubricant oil. The soilanalysis detected levels of aliphatic hydrocarbonsover three times above the Dutch InterventionValues, as indicated in table 12.<strong>UNEP</strong> inspects the damaged structure of the textile factory66 • United Nations Environment Programme • United Nations Environment Programme • United Nations Environment Programme •