Sustained Innovation and Creativity - Toyota Industries Corporation

Sustained Innovation and Creativity - Toyota Industries Corporation

Sustained Innovation and Creativity - Toyota Industries Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

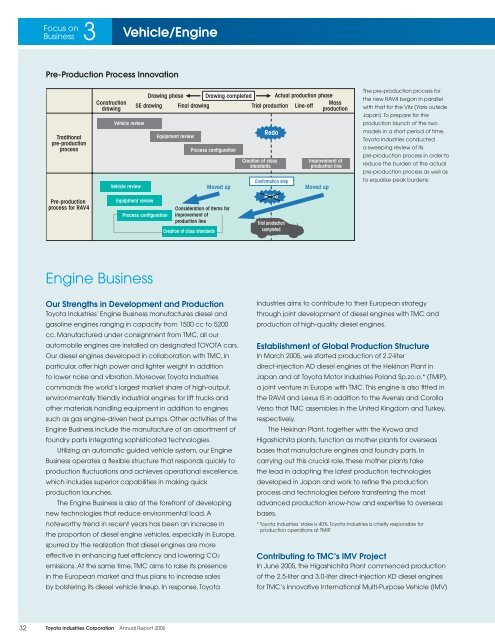

Focus onBusiness3Vehicle/EnginePre-Production Process <strong>Innovation</strong>Traditionalpre-productionprocessPre-productionprocess for RAV4ConstructiondrawingVehicle reviewVehicle reviewDrawing phase Drawing completed Actual production phaseSE drawing Final drawingTrial production Line-offMassproductionEquipment reviewProcess configurationMoved upEquipment reviewConsideration of items forProcess configuration improvement ofproduction lineCreation of class st<strong>and</strong>ardsRedoCreation of classst<strong>and</strong>ardsConfirmation stepRedoTrial productioncompletedImprovement ofproduction lineMoved upThe pre-production process forthe new RAV4 began in parallelwith that for the Vitz (Yaris outsideJapan). To prepare for theproduction launch of the twomodels in a short period of time,<strong>Toyota</strong> <strong>Industries</strong> conducteda sweeping review of itspre-production process in order toreduce the burden of the actualpre-production process as well asto equalize peak burdens.Engine BusinessOur Strengths in Development <strong>and</strong> Production<strong>Toyota</strong> <strong>Industries</strong>’ Engine Business manufactures diesel <strong>and</strong>gasoline engines ranging in capacity from 1500 cc to 5200cc. Manufactured under consignment from TMC, all ourautomobile engines are installed on designated TOYOTA cars.Our diesel engines developed in collaboration with TMC, inparticular, offer high power <strong>and</strong> lighter weight in additionto lower noise <strong>and</strong> vibration. Moreover, <strong>Toyota</strong> <strong>Industries</strong>comm<strong>and</strong>s the world’s largest market share of high-output,environmentally friendly industrial engines for lift trucks <strong>and</strong>other materials h<strong>and</strong>ling equipment in addition to enginessuch as gas engine-driven heat pumps. Other activities of theEngine Business include the manufacture of an assortment offoundry parts integrating sophisticated technologies.Utilizing an automatic guided vehicle system, our EngineBusiness operates a fl exible structure that responds quickly toproduction fl uctuations <strong>and</strong> achieves operational excellence,which includes superior capabilities in making quickproduction launches.The Engine Business is also at the forefront of developingnew technologies that reduce environmental load. Anoteworthy trend in recent years has been an increase inthe proportion of diesel engine vehicles, especially in Europe,spurred by the realization that diesel engines are moreeffective in enhancing fuel effi ciency <strong>and</strong> lowering CO2emissions. At the same time, TMC aims to raise its presencein the European market <strong>and</strong> thus plans to increase salesby bolstering its diesel vehicle lineup. In response, <strong>Toyota</strong><strong>Industries</strong> aims to contribute to their European strategythrough joint development of diesel engines with TMC <strong>and</strong>production of high-quality diesel engines.Establishment of Global Production StructureIn March 2005, we started production of 2.2-literdirect-injection AD diesel engines at the Hekinan Plant inJapan <strong>and</strong> at <strong>Toyota</strong> Motor <strong>Industries</strong> Pol<strong>and</strong> Sp.zo.o.* (TMIP),a joint venture in Europe with TMC. This engine is also fi tted inthe RAV4 <strong>and</strong> Lexus IS in addition to the Avensis <strong>and</strong> CorollaVerso that TMC assembles in the United Kingdom <strong>and</strong> Turkey,respectively.The Hekinan Plant, together with the Kyowa <strong>and</strong>Higashichita plants, function as mother plants for overseasbases that manufacture engines <strong>and</strong> foundry parts. Incarrying out this crucial role, these mother plants takethe lead in adopting the latest production technologiesdeveloped in Japan <strong>and</strong> work to refi ne the productionprocess <strong>and</strong> technologies before transferring the mostadvanced production know-how <strong>and</strong> expertise to overseasbases.* <strong>Toyota</strong> <strong>Industries</strong>’ stake is 40%. <strong>Toyota</strong> <strong>Industries</strong> is chiefl y responsible forproduction operations at TMIP.Contributing to TMC’s IMV ProjectIn June 2005, the Higashichita Plant commenced productionof the 2.5-liter <strong>and</strong> 3.0-liter direct-injection KD diesel enginesfor TMC’s Innovative International Multi-Purpose Vehicle (IMV)32 <strong>Toyota</strong> <strong>Industries</strong> <strong>Corporation</strong> Annual Report 2006

![PDF[476KB/5 pages] - Toyota Industries Corporation](https://img.yumpu.com/50288545/1/190x123/pdf476kb-5-pages-toyota-industries-corporation.jpg?quality=85)

![PDF[622KB/13pages] - Toyota Industries Corporation](https://img.yumpu.com/47399131/1/190x245/pdf622kb-13pages-toyota-industries-corporation.jpg?quality=85)

![PDF[792KB/2Pages] - Toyota Industries Corporation](https://img.yumpu.com/45510108/1/184x260/pdf792kb-2pages-toyota-industries-corporation.jpg?quality=85)

![PDF[126KB/4Pages] - Toyota Industries Corporation](https://img.yumpu.com/41525474/1/184x260/pdf126kb-4pages-toyota-industries-corporation.jpg?quality=85)

![PDF[1229KB/26 pages] - Toyota Industries Corporation](https://img.yumpu.com/40908773/1/190x247/pdf1229kb-26-pages-toyota-industries-corporation.jpg?quality=85)