Sustained Innovation and Creativity - Toyota Industries Corporation

Sustained Innovation and Creativity - Toyota Industries Corporation

Sustained Innovation and Creativity - Toyota Industries Corporation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

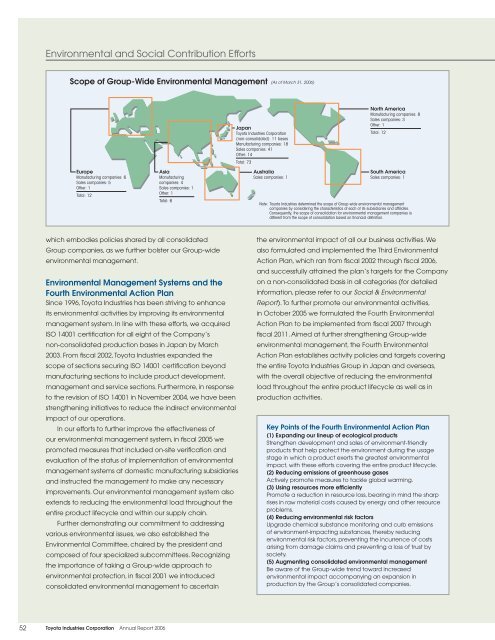

Environmental <strong>and</strong> Social Contribution EffortsScope of Group-Wide Environmental Management (As of March 31, 2006)Japan<strong>Toyota</strong> <strong>Industries</strong> <strong>Corporation</strong>(non-consolidated): 11 basesManufacturing companies: 18Sales companies: 41Other: 14Total: 73North AmericaManufacturing companies: 8Sales companies: 3Other: 1Total: 12EuropeManufacturing companies: 6Sales companies: 5Other: 1Total: 12AsiaManufacturingcompanies: 4Sales companies: 1Other: 1Total: 6AustraliaSales companies: 1South AmericaSales companies: 1Note: <strong>Toyota</strong> <strong>Industries</strong> determined the scope of Group-wide environmental managementcompanies by considering the characteristics of each of its subsidiaries <strong>and</strong> affiliates.Consequently, the scope of consolidation for environmental management companies isdifferent from the scope of consolidation based on financial definition.which embodies policies shared by all consolidatedGroup companies, as we further bolster our Group-wideenvironmental management.Environmental Management Systems <strong>and</strong> theFourth Environmental Action PlanSince 1996, <strong>Toyota</strong> <strong>Industries</strong> has been striving to enhanceits environmental activities by improving its environmentalmanagement system. In line with these efforts, we acquiredISO 14001 certifi cation for all eight of the Company’snon-consolidated production bases in Japan by March2003. From fi scal 2002, <strong>Toyota</strong> <strong>Industries</strong> exp<strong>and</strong>ed thescope of sections securing ISO 14001 certifi cation beyondmanufacturing sections to include product development,management <strong>and</strong> service sections. Furthermore, in responseto the revision of ISO 14001 in November 2004, we have beenstrengthening initiatives to reduce the indirect environmentalimpact of our operations.In our efforts to further improve the effectiveness ofour environmental management system, in fi scal 2005 wepromoted measures that included on-site verifi cation <strong>and</strong>evaluation of the status of implementation of environmentalmanagement systems at domestic manufacturing subsidiaries<strong>and</strong> instructed the management to make any necessaryimprovements. Our environmental management system alsoextends to reducing the environmental load throughout theentire product lifecycle <strong>and</strong> within our supply chain.Further demonstrating our commitment to addressingvarious environmental issues, we also established theEnvironmental Committee, chaired by the president <strong>and</strong>composed of four specialized subcommittees. Recognizingthe importance of taking a Group-wide approach toenvironmental protection, in fi scal 2001 we introducedconsolidated environmental management to ascertainthe environmental impact of all our business activities. Wealso formulated <strong>and</strong> implemented the Third EnvironmentalAction Plan, which ran from fi scal 2002 through fi scal 2006,<strong>and</strong> successfully attained the plan’s targets for the Companyon a non-consolidated basis in all categories (for detailedinformation, please refer to our Social & EnvironmentalReport). To further promote our environmental activities,in October 2005 we formulated the Fourth EnvironmentalAction Plan to be implemented from fi scal 2007 throughfi scal 2011. Aimed at further strengthening Group-wideenvironmental management, the Fourth EnvironmentalAction Plan establishes activity policies <strong>and</strong> targets coveringthe entire <strong>Toyota</strong> <strong>Industries</strong> Group in Japan <strong>and</strong> overseas,with the overall objective of reducing the environmentalload throughout the entire product lifecycle as well as inproduction activities.Key Points of the Fourth Environmental Action Plan(1) Exp<strong>and</strong>ing our lineup of ecological productsStrengthen development <strong>and</strong> sales of environment-friendlyproducts that help protect the environment during the usagestage in which a product exerts the greatest environmentalimpact, with these efforts covering the entire product lifecycle.(2) Reducing emissions of greenhouse gasesActively promote measures to tackle global warming.(3) Using resources more effi cientlyPromote a reduction in resource loss, bearing in mind the sharprises in raw material costs caused by energy <strong>and</strong> other resourceproblems.(4) Reducing environmental risk factorsUpgrade chemical substance monitoring <strong>and</strong> curb emissionsof environment-impacting substances, thereby reducingenvironmental risk factors, preventing the incurrence of costsarising from damage claims <strong>and</strong> preventing a loss of trust bysociety.(5) Augmenting consolidated environmental managementBe aware of the Group-wide trend toward increasedenvironmental impact accompanying an expansion inproduction by the Group’s consolidated companies.52 <strong>Toyota</strong> <strong>Industries</strong> <strong>Corporation</strong> Annual Report 2006

![PDF[476KB/5 pages] - Toyota Industries Corporation](https://img.yumpu.com/50288545/1/190x123/pdf476kb-5-pages-toyota-industries-corporation.jpg?quality=85)

![PDF[622KB/13pages] - Toyota Industries Corporation](https://img.yumpu.com/47399131/1/190x245/pdf622kb-13pages-toyota-industries-corporation.jpg?quality=85)

![PDF[792KB/2Pages] - Toyota Industries Corporation](https://img.yumpu.com/45510108/1/184x260/pdf792kb-2pages-toyota-industries-corporation.jpg?quality=85)

![PDF[126KB/4Pages] - Toyota Industries Corporation](https://img.yumpu.com/41525474/1/184x260/pdf126kb-4pages-toyota-industries-corporation.jpg?quality=85)

![PDF[1229KB/26 pages] - Toyota Industries Corporation](https://img.yumpu.com/40908773/1/190x247/pdf1229kb-26-pages-toyota-industries-corporation.jpg?quality=85)