4000 Switch Machine - Alstom

4000 Switch Machine - Alstom

4000 Switch Machine - Alstom

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

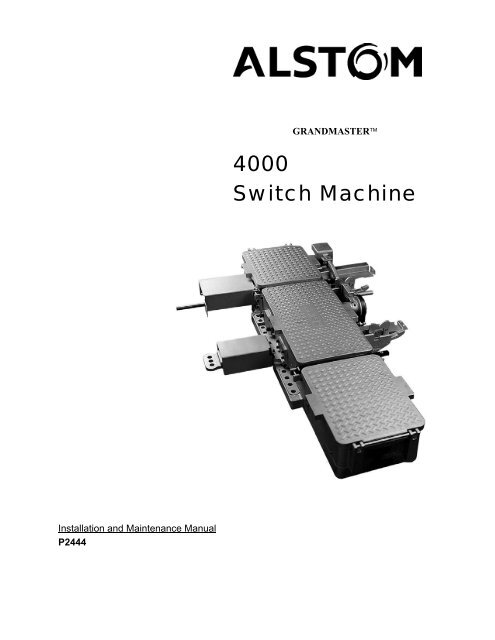

GRANDMASTER<strong>4000</strong><strong>Switch</strong> <strong>Machine</strong>Installation and Maintenance ManualP2444

GRANDMASTER<strong>4000</strong><strong>Switch</strong> <strong>Machine</strong>Copyright© 2000, 2002, 2007 ALSTOM Signaling Inc.Installation and Maintenance ManualALSTOM SIGNALING INC.P2444, Rev. January 2007 Printed in U.S.A.

LIST OF EFFECTIVE PAGESP2444, GrandMaster <strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>ORIGINAL ISSUE DATE:CURRENT REVISION AND DATE:CURRENT CHANGE AND DATE:Sep/00Jan/07NONEPAGECHANGE ORREVISION LEVELCoverNONETitle PageNONEi thru viNONEPrefaceNONE1-1 thru 1-12 NONE2-1 thru 2-10 NONE3-1 thru 3-34 NONE4-1 thru 4-12 NONE5-1 thru 5-6 NONE6-1 thru 6-22 NONE7-1 thru 7-10 Page 7-7, item 44 updated from -01 to -02 (-01 is obsolete)A-1 thru A-32 NONEP2444, Rev. Jan/07 ALSTOM Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANKP2444, Rev. Jan/07 ALSTOM Signaling Inc.

TABLE OF CONTENTSSECTION 1 - GENERAL DESCRIPTIONSCOPE OF MANUAL ................................................................................................................ 1-1SWITCH MACHINE OVERVIEW ............................................................................................ 1-1FEATURES ................................................................................................................................. 1-2Modular Design .....................................................................................................................1-2Configurable Latchout ...........................................................................................................1-2Operating Power Configurations ...........................................................................................1-2Manual Operation <strong>Switch</strong> ......................................................................................................1-2Electronic Clutch ...................................................................................................................1-3Slip Link Cam Bar .................................................................................................................1-3Configuration Plug.................................................................................................................1-3MAJOR COMPONENTS............................................................................................................ 1-4Covers ....................................................................................................................................1-4Guards....................................................................................................................................1-4Latch Stand Module...............................................................................................................1-4Hand Throw Module.............................................................................................................. 1-4Amplifier................................................................................................................................1-6Electrical Harness ..................................................................................................................1-6Motor .....................................................................................................................................1-65:1 Gearbox............................................................................................................................1-630:1 Gearbox..........................................................................................................................1-7Main Drive.............................................................................................................................1-7Point Detector <strong>Switch</strong> Module...............................................................................................1-7Point Detector System Module ..............................................................................................1-7Lock Rod ...............................................................................................................................1-8Point Detector Rod ................................................................................................................1-8Cam Bar .................................................................................................................................1-8Throw Bar ..............................................................................................................................1-8Cross Brace ............................................................................................................................1-8SAFETY PRECAUTIONS FOR MAINTAINERS................................................................... 1-10General Requirements..........................................................................................................1-10Proper Attire ........................................................................................................................1-10General Safety on Transit Property .....................................................................................1-10Safety at Trackside...............................................................................................................1-11Safety at <strong>Switch</strong> <strong>Machine</strong>s...................................................................................................1-11P2444, Rev. Jan/07 iALSTOM Signaling Inc.

TABLE OF CONTENTS (Cont.)SECTION 2 - THEORY OF OPERATIONINTRODUCTION ....................................................................................................................... 2-1DRIVE TRAIN ............................................................................................................................ 2-1SEQUENCE OF OPERATION................................................................................................... 2-1SWITCH MACHINE CONTROL............................................................................................... 2-2Fail Safe Features...................................................................................................................2-2Universal Features .................................................................................................................2-3NORMAL AND REVERSE LOCKING..................................................................................... 2-4POINT DETECTION .................................................................................................................. 2-5LATCHOUT................................................................................................................................ 2-7SECTION 3 - INSTALLATIONGENERAL................................................................................................................................... 3-1PROPERTY'S REQUIREMENTS .............................................................................................. 3-2INSTALLATION PROCEDURES.............................................................................................. 3-2<strong>Switch</strong> <strong>Machine</strong> Inspection....................................................................................................3-2<strong>Switch</strong> Layout ........................................................................................................................3-3<strong>Switch</strong> <strong>Machine</strong> Mounting.....................................................................................................3-4Electrical Wiring....................................................................................................................3-5Field Wiring..................................................................................................................... 3-5Motor Wiring ................................................................................................................... 3-6Wiring Configuration....................................................................................................... 3-8<strong>Switch</strong> <strong>Machine</strong> Connecting and Adjusting ..........................................................................3-9Throw Rod .......................................................................................................................3-9Lock Rod........................................................................................................................ 3-10Connect and Initially Adjust Point-Detector Rod.......................................................... 3-12Motor Limit Adjustment................................................................................................ 3-14<strong>Switch</strong> <strong>Machine</strong> Operation ..................................................................................................3-15Hand Crank .................................................................................................................... 3-15Hand Throw ................................................................................................................... 3-17Manual Operating <strong>Switch</strong> .............................................................................................. 3-18LEFT-HAND OR RIGHT-HAND CONFIGURATION........................................................... 3-19Throw Bar ............................................................................................................................3-19Lock and Detector Rods ......................................................................................................3-20Hand Throw Lever and Latch Stands ..................................................................................3-21BEFORE PLACING MACHINE IN SERVICE ....................................................................... 3-23P2444, Rev. Jan/07 iiALSTOM Signaling Inc.

TABLE OF CONTENTS (Cont.)SECTION 4 - SCHEDULED MAINTENANCEINTRODUCTION ....................................................................................................................... 4-1SPECIAL TOOLS AND TEST EQUIPMENT ........................................................................... 4-1Hand Crank ............................................................................................................................4-1AFTER FLOODING ................................................................................................................... 4-2LUBRICATION GUIDELINES ................................................................................................. 4-2PREVENTIVE MAINTENANCE INDEX ................................................................................. 4-2SITE INSPECTION..................................................................................................................... 4-3PREVENTIVE MAINTENANCE CHECKS.............................................................................. 4-3Point Pressure Test.................................................................................................................4-4<strong>Switch</strong> Obstruction Test # 17.................................................................................................4-4Point Detector Check .............................................................................................................4-5External PM Checks ..............................................................................................................4-5Internal PM Checks ...............................................................................................................4-6LOCK ROD AND POINT DETECTOR ADJUSTMENTS........................................................ 4-9Lock Rod Adjustment (Narrow Notch) .................................................................................4-9Lock Rod Adjustment (Wide Notch).....................................................................................4-9Point-Detector Rod Adjustment...........................................................................................4-10WEAR PLATE REPLACEMENT ............................................................................................ 4-12SECTION 5 - TROUBLESHOOTINGPHILOSOPHY............................................................................................................................. 5-1TROUBLESHOOTING............................................................................................................... 5-1Amplifier LED Display..........................................................................................................5-4Amplifier Fuse .......................................................................................................................5-6SECTION 6 - CORRECTIVE MAINTENANCEPURPOSE.................................................................................................................................... 6-1REMOVAL AND REPLACEMENT PROCEDURES ............................................................... 6-1Covers ....................................................................................................................................6-2Cross Brace ............................................................................................................................6-3Amplifier................................................................................................................................6-4<strong>Switch</strong>es .................................................................................................................................6-5Brushless DC Motor and 5:1 Gearbox...................................................................................6-630:1 Gearbox..........................................................................................................................6-8Hand Throw Lever...............................................................................................................6-10P2444, Rev. Jan/07 iiiALSTOM Signaling Inc.

TABLE OF CONTENTS (Cont.)Latch Stand ..........................................................................................................................6-12Main Drive...........................................................................................................................6-13Lock Rod..............................................................................................................................6-15Point Detector Module.........................................................................................................6-15Point Detector <strong>Switch</strong> Module.............................................................................................6-17Point Detector Rod...............................................................................................................6-18Housing................................................................................................................................6-19Throw Bar ............................................................................................................................6-20Cam Bar ...............................................................................................................................6-21Throw Bar and Lock Rod Wear Plate Assembly.................................................................6-22SECTION 7 - PARTS CATALOGGENERAL................................................................................................................................... 7-1PARTS LIST................................................................................................................................ 7-1APPENDIX A - DRAWINGSOVERVIEW ............................................................................................................................... A-1WIRING AND CIRCUIT APPLICATIONS.............................................................................. A-2INSTALLATION AND SPACE REQUIREMENTS............................................................... A-12P2444, Rev. Jan/07 ivALSTOM Signaling Inc.

LIST OF FIGURESFigure No. Description Page1-1 Model GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong> - Exterior View .............................................. 1-51-2 Model GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong> - Interior View ............................................... 1-92-1 Throw Bar Locking Position................................................................................ 2-42-2 Latch Out Components ........................................................................................ 2-83-1 Typical GM<strong>4000</strong> <strong>Switch</strong> Layout ......................................................................... 3-13-2 Throw Rod Clearance .......................................................................................... 3-33-3 Typical Mounting of GM<strong>4000</strong>............................................................................. 3-43-4 Typical GM<strong>4000</strong> Internal Wiring Components................................................... 3-63-5 Typical GM<strong>4000</strong> Internal Wiring Connections (TB1) ........................................ 3-73-6 Terminal Wiring and Configuration Plug Location............................................. 3-83-7 Throw Rod Connection Hardware..................................................................... 3-103-8 Lock Rod Connection Hardware ....................................................................... 3-103-9 Lock Rod Features and Components ................................................................. 3-113-10 Point-Detector Rod Connection Hardware ........................................................ 3-123-11 Point-Detector Rod Adjustment Hardware........................................................ 3-143-12 GM<strong>4000</strong> Hand Crank Operation........................................................................ 3-163-13 Hand Throw Hardware ...................................................................................... 3-173-14 Manual Operation Hardware ............................................................................. 3-183-15 Throw Bar (Right and Left-Hand Configuration).............................................. 3-193-16 Lock and Detector Rod (Right and Left-Hand Configuration).......................... 3-203-17 Hand Throw Lever and Latch Stand Components............................................. 3-224-1 Internal GM<strong>4000</strong> Components ............................................................................ 4-74-2 Point-Detector Rod Adjustment Components ................................................... 4-116-1 Cover Removal and Replacement Components .................................................. 6-26-2 Cross Brace Removal and Replacement Components......................................... 6-36-3 Amplifier Removal and Replacement Components ............................................ 6-56-4 <strong>Switch</strong> Removal and Replacement Components ................................................. 6-66-5 Motor and Gearbox Removal and Replacement Components............................. 6-86-6 Gearbox Removal and Replacement Components .............................................. 6-96-7 Hand Throw Lever Removal and Replacement Components............................ 6-116-8 Latch Stand Removal and Replacement Components....................................... 6-126-9 Main Drive Removal and Replacement Components........................................ 6-146-10 Point Detector Module Removal and Replacement Components...................... 6-16P2444, Rev. Jan/07 vALSTOM Signaling Inc.

LIST OF FIGURES (Cont.)Figure No. Description Page6-11 Point Detector <strong>Switch</strong> Module Removal and Replacement Components ......... 6-186-12 Wear Plate Assembly Removal and Replacement ............................................ 6-227-1 Typical GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>....................................................................... 7-3P2444, Rev. Jan/07 viALSTOM Signaling Inc.

LIST OF TABLESTable No. Description Page2-1 <strong>Switch</strong> Movement ............................................................................................... 2-54-1 Preventive Maintenance Index............................................................................. 4-25-1 Troubles Noticed from the Control Locations..................................................... 5-25-2 Trackside Noted Symptoms................................................................................. 5-3P2444, Rev. Jan/07 viiALSTOM Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANKP2444, Rev. Jan/07 viiiALSTOM Signaling Inc.

PREFACEABOUT THE MANUALThis manual is intended to provide the necessary information to maintain and ensure properoperation of an ALSTOM GrandMaster <strong>4000</strong> (GM<strong>4000</strong>) <strong>Switch</strong> <strong>Machine</strong>. The informationprovided is not limited to the components of the switch machine. Most of the drawings withinthis manual are final or approved. Some of the drawings that contain hardware not subject tochange have been finalized and call-outs added. The balance of the drawings with call-outs willbe added to this manual upon finalization.The information in this manual is arranged into sections. The title and a brief description of eachsection follow:Section 1 - General DESCRIPTION: This section gives general information on thecomponents of the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>. Safety precautions are also provided in thissection.Section 2 - THEORY OF OPERATION: This section gives general information on theoperation of the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>. Safety precautions are also provided in this section.SECTION 3 - INSTALLATION: This section describes the field installation and setup of theGM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>.Section 4 - PREVENTIVE MAINTENANCE: This section describes the tools, preventivemaintenance procedures, and functional tests used on the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>. Thefrequency and interval, for the performance of the given information, are also included.Section 5 - TROUBLESHOOTING: This section describes possible failures/symptoms alongwith the corrective action for the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>.Section 6 - CORRECTIVE MAINTENANCE: This section describes the adjustment andreplacement procedures associated with corrective maintenance of the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>.Section 7 - PARTS CATALOG: This section identifies and lists the spare parts associated withoperations of the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>.APPENDIX A - DRAWINGS: this section has representative circuit drawings along with aninstallation and space requirement drawing of the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>.P2444, Rev. Jan/07 ALSTOM Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANKP2444, Rev. Jan/07 ALSTOM Signaling Inc.

SECTION 1GENERAL DESCRIPTIONSCOPE OF MANUALThe purpose of this manual is to describe features of the ALSTOM GrandMaster <strong>4000</strong>(GM<strong>4000</strong>) electric switch machine and describe how to properly inspect, service, test, remove,and replace the recommended spare parts.SWITCH MACHINE OVERVIEWThe universal design concept of the ALSTOM model GM<strong>4000</strong> electric switch machine allowsutilization at interlockings and derails regardless of the variations with existing switch machines,available power, and weights of rail. It is especially suitable for use in subways or on rapidtransit properties.The GM<strong>4000</strong> weighs approximately 1000 pounds, measures 67.25 inches long, 40.83 incheswide, and 8.13 inches high and has a 6.5 inch stroke. The switch machine produces <strong>4000</strong> poundsof thrust utilizing 110V (AC or DC) operating energy.The GM<strong>4000</strong> switch machine incorporates all of the features required to meet interlockingpractices. Some additional features include configurable latchout, operating powerconfigurations, manual operation switch, an electronic clutch, and a slip link cam bar.WARNING<strong>Switch</strong> Calls, for a duration of 150 milliseconds or greater, will beginthe switch machine unlocking process. If this condition exists, due tothe control system used, a timing relay is required in the circuitconnected to the switch machine.P2444, Rev. Jan/07 1-1ALSTOM Signaling Inc.

FEATURESThe GM<strong>4000</strong> is designed for long life and low maintenance, and helps reduce inventory due toits field configurable change-out design. Its long life and low maintenance are attributable to alow stressed mechanical system, dry film lubrication (DFL), brushless motor, solid stateamplifier, and significantly fewer parts than existing switch machines. The ease of fieldconfigurable change out is the result of a modular design concept with fewer and simplifiedadjustments.The switch machine can be manually operated, utilizing supplied power, through a manualoperation switch located near the motor. The switch machine can be manually operated, withoututilizing supplied power, through the use of the hand-throw lever or hand crank. The hand crankoperation is provided for making or checking setup adjustments when power is not available.When power is available, manual operation through the use of the manual operation switch isrecommended. These machine operating procedures are described in Section 2 of this manual.Modular DesignThe modular design of the GM<strong>4000</strong> allows for ease of assembly and corrective maintenance.Module locating pins in the switch machine base and a modular weight limit of 85 pounds, withmost module weight less than 50 pounds, make it possible to remove and replace switch machinemodules at trackside. Module removal and replacement procedures are described in Section 6 ofthis manual.Configurable LatchoutThe latchout capabilities of the GM<strong>4000</strong> are configurable for location requirements and can beimplemented or removed from the GM<strong>4000</strong>. Implemented latchout can be set for a restorable ornon-restorable configuration. This feature is described in Section 2 of this manual.Operating Power ConfigurationsThe GM<strong>4000</strong> functions without additional hardware in a number of supplied power conditions(24 VDC, 110 VDC, or 110 VAC). This feature is described in the following sections of thismanual.Manual Operation <strong>Switch</strong>The GM<strong>4000</strong> can be field operated under power as long as a switch call is present and the switchmachine amplifier is set in the “Local” operation mode. This operation is described in thefollowing sections of this manual.P2444, Rev. Jan/07 1-2ALSTOM Signaling Inc.

Electronic ClutchThe amplifier, utilized as an electronic clutch, uses current limit to determine the overload trippoint of the motor. When the current limit is reached, a 5-second timer starts. After 5 seconds,the overload trip point is reached and the overload circuit shuts down power to the motor. Toresume operation, either reverse the switch call or remove and restore supplied operationalpower.Slip Link Cam BarWhen the lock rod is out of position relative to the cam bar locking dog, a fouled conditionoccurs. The slip link allows the cam bar to separate so the throw bar can complete strokewithout locking the lock rod or indicating position (normal or reverse). This occurrence allowsswitch points to be moved by the hand throw device. With the lock rod out of position, the splitlinkfeature permits the hand throw lever to be positioned in the latch stand.Configuration PlugThe configuration plug sets the switch machine for a 3-wire, 4-wire, or 5-wire application(typical ALSTOM and US&S wiring applications). Two configuration plugs are labeled andshipped with the machine. The 3-wire plug is utilized for both 3-wire and 5-wire applications.P2444, Rev. Jan/07 1-3ALSTOM Signaling Inc.

MAJOR COMPONENTSThe components of a mainline GM<strong>4000</strong> switch machine are described in the followingparagraphs and shown in Figures 1-1 and 1-2.CoversThe GM<strong>4000</strong> has three light-weight aluminum covers, as shown in Figure 1-1, that protectinternal switch machine components from unwanted debris, water, or other material. Thesecovers are attached to the switch machine by a hold-down on the housing and a removable strapthat can be locked. An AAR wrench is required to remove or secure the straps that hold downthe center and end covers. The covers are removable and can be utilized as a tray to holdhardware or tools during maintenance.To remove a cover, a pivoting and upward pulling motion is required. The end covers attach tothe housing by slipping the thick cover lip underneath the 3/8-inch diameter rods on either end ofthe housing and pivoting cover down to allow housing wall to be captured by the gasket grooveof the cover.GuardsGuards of the GM<strong>4000</strong>, as shown in Figure 1-1, protect the space for lateral movement of thethrow bar, lock rod, and point detector rod by keeping away unwanted trackside debris, ballast,or other material.Latch Stand ModuleThe latch stand module, as shown in Figure 1-1, is a support fixture and most importantly, alocking fixture for the hand throw lever and selector lever. The module bolts directly to theswitch machine housing. The latch stand accommodates right or left hand switch machineconfigurations.Hand Throw ModuleThe hand throw module, as shown in Figure 1-1, is a manual means of switching tracks withoutelectrical power. While in a hand throw mode, the switch machine can complete stroke, lockswitch points, and indicate normal or reverse position.P2444, Rev. Jan/07 1-4ALSTOM Signaling Inc.

REAR COVER(GM050-006-00)HAND THROWMODULE(GM050-200-01)CENTER COVER(GM050-007-00)THROW BAR GUARDFIELD SIDE(GM050-030-00)SASIBSASIBGRSRAILWAYTHROW BAR GUARDTRACK SIDE(GM050-029-00)LATCH STAND MODULE(GM050-400-01)LOCK ROD GUARDTRACK SIDE(GM050-031-00)LOCK ROD GUARDFIELD SIDE(GM050-032-00)FRONT COVER(GM050-008-00)Figure 1-1. Model GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong> - Exterior ViewP2444, Rev. Jan/07 1-5ALSTOM Signaling Inc.

AmplifierThe amplifier, as shown in Figure 1-2, controls the brushless DC motor by reading the switchcall and configuring the motor power. The configured power causes the motor to turn in theproper direction. The amplifier monitors the condition of the GM<strong>4000</strong> and checks forobstructions, motor faults, and amplifier faults. LEDs mounted on the amplifier housing displaythe switch machine operational status. The amplifier features an electronic clutch, three motorspeeds, two current limits, inhibit circuits to disable the motor in a hand throw or hand crankmode, and non-restorable latchout.The amplifier can be set for 4-wire (model 5G/5H), 3-wire (model 5E/5F and M23), or 5-wire(model M23) switch machine configuration through the use of a configuration plug connected tothe amplifier. The amplifier is mounted to the switch machine housing. All electricalconnections to it are made by removable connectors. The amplifier and electrical connectionsare watertight and keyed to prevent damage to the amplifier. The amplifier is 2-1/4 inches wide,13-1/4 inches long, 5-1/4 inches high, and field replaceable, and weighs approximately 6 pounds.Electrical HarnessThe electrical harness, as shown in Figure 1-2, connects the amplifier to field electricalconnections at a terminal strip located at the point detector end of the switch machine. Theelectrical harness also connects limit switches located within some of the GM<strong>4000</strong> modules tothe amplifier. These limit switches provide feedback to the amplifier, stopping the motor atcompletion of a stroke. The switches and electrical connectors are watertight. The harness isalso connected to configuration jumpers (switch machine speed, current limit, and latch-out) andthe manual operation switch located within the motor end of the switch machine.MotorThe brushless DC motor, as shown in Figure 1-2, works with the amplifier to drive the switchmachine. The motor connects to the amplifier by a pigtail harness. The two-horsepower motorproduces 110 inch-pounds of torque at 2500 rpm and bolts to the 5:1 gearbox. The motor is 4-1/2 inches wide, 4-1/2 inches high, and 9 inches long. The motor weighs 12 pounds and is fieldreplaceable.5:1 GearboxThe 5:1 gearbox, as shown in Figure 1-2, reduces motor output speed while increasing motortorque. This gearbox is basically maintenance-free with spring loaded lip seals, grease packedsealed bearings, and a synthetic lubricant for the helical gearing.P2444, Rev. Jan/07 1-6ALSTOM Signaling Inc.

30:1 GearboxThe 30:1 gearbox, flex coupled to the 5:1 gearbox as shown in Figure 1-2, reduces motor speedwhile increasing drive torque. It uses spring loaded lip seals, synthetic lubricant, and lowstressed worm gearing.The gearbox has dual input, either the hand crank or the motor. Gearbox output of the spur geardrives the main gear with up to a possible 10,000 inch-pounds of torque.Main DriveThe main drive module’s patented low profile design, as shown in Figure 1-2, is the drivingforce and mechanical control of the switch machine. The main drive converts the rotatingmotion of the motor and gearboxes to linear motion of the cam bar and throw bar, both of whichhave cam surfaces designed to achieve proper stroke and timing with the lock rod and pointdetector rod.The hand crank function of the main drive module cuts out operational power to the motor(indicated by the “Remote/Local” LED of amplifier going off). The non-electrical operation ofthe switch machine is performed through the use of a hand crank.When a faster non-electrical operation of the main drive is desired, the hand throw system isused. The manual select lever of the hand throw shuts off electrical power prior to permittinghand throw operation, thus allowing fast manual operation of throw bar, cam bar, lock rod, andpoint detection system.Point Detector <strong>Switch</strong> ModuleThe point detector switch module, as shown in Figure 1-2, consists of two rotary cam switches(right and left) used to indicate the switch point position and switch machine correspondence.Each switch has six contacts. Two are used in the indication relay circuit for a correspondencecondition; two are used to shunt the relay circuit in mid-stroke; one is used in the latch outcircuit; and one is used in the point detector switch module LED circuit.Point Detector System ModuleThe point detector module, as shown in Figure 1-2, bolts to the switch machine base and is themechanical link between the point detector switches, lock rod, point detector rod, and cam bar.The point detector module, along with other modules of the point detector system, indicate to thetrain control room if a switch point position has moved off point and can be utilized to indicatenormal and reverse switch positioning.P2444, Rev. Jan/07 1-7ALSTOM Signaling Inc.

Lock RodThe lock rod, as shown in Figure 1-2, locks the front rod in position (normal or reverse) andconsists of two rods (curved and straight) that can be adjusted for varying stroke of 6.5 to 3.5inches. The lock rod accommodates right- or left-hand switch machine configurations.The lock rod can be either a wide or narrow notch configuration. A narrow notch will not allowthe machine to lock with a 1/4 inch obstruction, but a wide notch will. The lock rod can also beordered with a threaded or spade end connection.Point Detector RodThe point detector rod, as shown in Figure 1-2, is used to detect the position or movement of theswitch points and consists of three pieces that provide adjustment for varying (3.5 to 6.5 inches)switch machine stroke. The point detector rod can be ordered with a solid (threaded), spade, orthreaded swivel end connection.Cam BarThe split link cam bar, not visible in Figure 1-2, is located under the main drive module andpoint detection modules. The cam bar moves in a machined channel within the switch machinebase plate and is key to the operation of the point detector system. It is the mechanism that, inconjunction with the lock rod, locks the switch points in position. The cam bar also preventsindication while the switch machine is unlocked.The slip link feature allows the cam bar to separate when the cam bar dog interferes with thelock rod, during completion of stroke. When the lock rod is in adjustment, the cam bar willautomatically reset itself.Throw BarThe high strength throw bar, as shown in Figure 1-2, moves the switch points into position. Thelinear movement of the throw bar is generated by the integral cam and the rotary movement ofthe main drive crank. The high wear-resistant nickel plating eliminates the need of lubrication.Cross BraceThe cross brace, as shown in Figure 1-2, is connected to the switch machine housing andsupports the covers. Two cross braces are utilized in the switch machine and can be removedwhen required to give additional access to switch machine components.P2444, Rev. Jan/07 1-8ALSTOM Signaling Inc.

MOTOR(GM050-020-00)AMPLIFIER(GM050-024-00)5:1 GEARBOX(GM050-026-00)CROSS BRACE(GM050-005-00)30:1 GEARBOX(GM050-025-00)ELECTRICAL HARNESS(GM050-900-01)THROW BAR(GM050-002-00)MAIN DRIVE(GM050-100-01)LOCK ROD(GM050-300-0_ )POINT DETECTORSWITCH MODULE(GM050-800-01)POINT DETECTOR ROD(GMO5O-500-0_ )POINT DETECTORSYSTEM MODULE(GM050-700-01)Figure 1-2. Model GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong> - Interior ViewP2444, Rev. Jan/07 1-9ALSTOM Signaling Inc.

SAFETY PRECAUTIONS FOR MAINTAINERSSafe practices and common sense should always be used when working around any equipment.Remember that good common sense and an understanding of the equipment is essential to anysafety policy. The following describes health and safety standards for testing, alterations,repairs, improvements, or maintenance and applies to all maintenance personnel.Note: Only authorized personnel who have reviewed and understand the informationcontained in this manual should be working on or around the switch machine.General RequirementsMaintenance personnel shall comply with all local laws, rules, statutes, and regulations ofgoverning or regulatory bodies within the geographical area of operation of the property (orAuthority). The requirements of these bodies or the user’s safety manual, whichever is morestringent, shall apply. When specific standards and details are not set forth in the manual, jobspecifications, or in the local laws and regulations referenced, standards published by theOccupational Safety and Health Administration (OSHA) shall apply.Proper Attire1. Wear hard hats at all times.2. Wear work shoes that are in good repair. Sneakers or tennis shoes are unsafe.3. Wear clothing of proper fit. Loose fitting clothing is a hazard.4. Avoid wearing belt-type key rings, and never carry tools in hip pockets.General Safety on Transit Property1. Never go out on a track of an operating railroad alone. Flagmen familiar with operatingprocedures and safety regulations must accompany all field maintenance personnel formaximum safety.2. Always be alert and watchful as if each man were by himself. Be aware of the area youand others are in at all times. Yell or signal a warning if a dangerous situation develops.P2444, Rev. Jan/07 1-10ALSTOM Signaling Inc.

Safety at Trackside1. Check for a safe place to go before starting a job and be sure that enough safe places areavailable for all personnel on the track. Avoid sudden unplanned moves.2. Never attempt to complete a job when a train is approaching.3. Stand along the track in a clear area, stand where the train operator can see you, and takeprecautionary measures.4. When crossing the tracks in front of or behind a stopped train, cross at a great enoughdistance from the train to be prepared for the train to proceed in either direction.5. If boarding or dismounting a train, wait until the train comes to a full stop and theoperator gives his or her permission. When carrying equipment or plans, always handthem up or down to allow free use of your hands.6. Never step or walk on rails. Slipping off may result in serious injury.7. Never lay tools or equipment on the rails. Objects left on a rail may derail or damage atrain and flying debris could endanger personnel along the track.8. When taking shelter from an approaching train, always watch for a train on the adjacenttrack.9. Exercise special caution in tunnels, curves, and turnouts and on grades, as it is verydifficult to determine the direction from which a train is approaching and its distanceaway.Safety at <strong>Switch</strong> <strong>Machine</strong>s1. Keep fingers, feet, tools, and equipment out of switch points. Closing points can trap andcrush hands and feet or damage tools and equipment. A wedge properly inserted betweenpoints will prevent an inadvertently energized switch machine from causing personalinjury or equipment damage.2. Never step on switch rods. Rod movement can cause serious foot injury or loss ofbalance.3. Because the switch machine is often operated from a remote station (a local controlroom), be sure to notify this station that maintainers are working on or around a givenswitch machine. This notification may prevent the equipment from being activatedduring the reported service.Note: For safety when working on machine and power is not required: 1) place"LOCAL/REMOTE" switch on amplifier, in the local position; 2) rotate the handcrank cover to the open position to inhibit power to the motor.4. When covers are removed from switch machine and gearing is exposed, keep fingersaway from gearing.P2444, Rev. Jan/07 1-11ALSTOM Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANKP2444, Rev. Jan/07 1-12ALSTOM Signaling Inc.

SECTION 2THEORY OF OPERATIONINTRODUCTIONThe following is a functional overview of the GM<strong>4000</strong> <strong>Switch</strong> <strong>Machine</strong>. The operation of afunctional area is described along with associated modules and components.DRIVE TRAINThe GM<strong>4000</strong> switch machine drive train consists of a motor, two gearboxes, and a main drivemodule. The motor is bolted to and drives a 5:1 gearbox. The 5:1 gearbox is coupled to anddrives a 30:1 gearbox. The 30:1 gearbox drives 1.58:1 open spur gears. The splined main drivecrank converts the rotational movement of gears into a linear movement of the throw bar andcam bar. This drive train, along with the throw bar, provides the thrust required to throw aswitch in 4, 9, or 15 seconds in 110V (AC or DC) applications and 17 seconds in 24 VDCapplications. Note that the speed of machine switching is dependent on supplied voltage.SEQUENCE OF OPERATIONThe correct order of operation for the GM<strong>4000</strong> switch machine is as follows:1. Break indication2. Unlock3. Throw4. Lock5. Indicate if switch points are in correct positionP2444, Rev. Sep/00 2-1 ALSTOM Signaling Inc.

SWITCH MACHINE CONTROLThe GM<strong>4000</strong> uses a brushless DC motor and amplifier to drive the gear train. A brushless DCmotor contains a permanent magnet armature that rotates and drives the 5:1 gearbox. The motorcontains three field coils that surround the armature. The amplifier energizes and de-energizesthe three field coils in a circular fashion. This creates a rotating magnetic field that pulls thearmature around.There are three hall sensors that monitor the armature and provide position information to theamplifier. This information is used to control the circuitry that powers the three field coils.Together, the hall sensors and the amplifier regulate the motor’s RPM. The motor’s RPM isindependent of the switch machine’s load. This implies that as the switch machine’s loadvaries, the switch machine’s throw time remains constant (the switch machine doesn’t slowdown as the load increases).The amplifier also monitors the motor’s current. Motor current is directly proportional to motortorque. As the switch machine sees an increased load such as point pressure or an obstruction,the motor sees an increased load. The amplifier senses the increased load on the motor andsupplies more current to the motor thus increasing the motor torque. This additional motortorque increases the switch machine’s output force up to <strong>4000</strong> pounds.Fail Safe FeaturesThe universal switch machine amplifier is fail safe. Fail Safe, as used in the signaling contextmeans that no failure will cause the system to be less safe than it would be if the failure had notoccurred. That is, a failure will leave the system at least as safe as it was before the occurrenceof the failure. One of the fail safe properties is that the motor cannot turn on at the wrong time.For example, if the motor uses a transistor as a power switch and the transistor shorts out due toa surge, the motor cannot be allowed to turn on. The same holds true for the control lines on themotor controller. If there are transistors or transistor junctions used as switches on the controllines and one of them shorts out, the motor again cannot be allowed to run. Any failure mode ofany part of the circuitry cannot cause the motor to operate. This includes transistor junctionsshorting, opening or shorting to ground. A failure, or combination of failures, cannot cause orpermit the motor to operate without the presence of a proper control signal (i.e. switch call).The amplifier consists of two functional blocks. The first is the MOTOR DRIVER. There is onedriver that switches power to each motor coil. If any or all of the drivers short out, the field coilassociated with the damaged driver could be energized but it would not be de-energized at theappropriate time. The result: the motor would stop running.P2444, Rev. Jan/07 2-2ALSTOM Signaling Inc.

The second is the AMPLIFIER, the device controlling the timing signals that control the motordriver. The amplifier controls the direction and the speed of the motor. The amplifier receivesits power only from the switch machine control lines (i.e. switch call). The amplifier can onlygenerate the proper sequence of signals when the control lines are energized therefore the motorcan only run when the control lines are energized. Isolation will prevent the motor power fromenergizing the amplifier.When the hand throw cut out limit switch or the hand crank cut out limit switch opens, the powerto the amplifier is removed. This vitally disables the motor. The hand throw switch and thehand crank switch are both positive break limit switches. A positive break switch contains amechanism that breaks open frozen or welded contacts.Universal FeaturesThe amplifier has a universal power supply. The GM<strong>4000</strong> motor will operate at a power voltagerange of 13 to 140 VDC or 88 to 140 VAC. There are no jumpers or special configurationsneeded for the amplifier to work over this wide voltage range.The system has three speed settings available if the supply voltage is above 85 volts (DC or AC).By installing the proper speed configuration jumper, the amplifier sets the motor RPM to allowthe switch machine to throw in 4, 9, or 15 seconds. Below 85 volts, speeds will decreaseproportionally with voltage.The system has two current settings. High-current mode allows the machine to push up to <strong>4000</strong>pounds. The peak current is 35 amps. The external fuses must be rated at 17 amps. Lowcurrentmode allows the machine to push up to 2800 pounds. External fuses must be rated at 12amps.The optimal installation is the high-voltage, high-current mode since this provides the systemwith the most output force and allows for speed configuration. The universal power supplyallows the system to run at high-voltage with the maximum force out and have a low-voltagebattery backup. A low-voltage battery backup could supply a minimum of 2500 pound loadrequirement.The amplifier will run off all input configurations. It can be installed in a 3-wire mode (Model5E/5F or M23), 4-wire mode (Model 5G/5H), or 5-wire mode (Model M23).P2444, Rev. Jan/07 2-3ALSTOM Signaling Inc.

NORMAL AND REVERSE LOCKINGBoth the throw bar and lock rod must be locked at end of stroke in the “normal” and “reverse”switch point positions.The throw bar is locked when the crank has traveled over the center of the throw bar, as shownin Figure 2-1. When the crank is in the over-center position any load on the throw bar (pointpressure) drives the crank roller into the locking pocket of the throw bar. The cogging action ofthe motor and the gear train hold the crank in the over-center position if there is no load on thethrow bar (point pressure).The lock rod is locked when the cam bar dog is centered in the notch of the lock rod. If thecrank isn’t over center of the throw bar or the cam bar dog isn’t centered in the lock rod notchthen the motor limit cams must be adjusted per the Motor Limit <strong>Switch</strong> Adjustment Procedure.POSITION MARKS(LOCKED POSITION)CRANKTHROWBARMID-STROKE(UN-LOCKED)POSITIONMARKSFigure 2-1. Throw Bar Locking PositionP2444, Rev. Jan/07 2-4ALSTOM Signaling Inc.

POINT DETECTIONThere are five modules that interact to perform point detection. They are the point detectorsystem module, the point detector switch module, the point detector rod, the lock rod, and thecam bar. See the module descriptions for a detailed explanation.The point detector switch module contains two “positive break” rotary cam switches. Oneswitch rotates clockwise and one rotates counter-clockwise. A positive break switch contains amechanism that breaks open frozen or welded contacts. Each rotary cam switch consists of sixswitches for indication, shunting, latchout, and continuity checking. <strong>Switch</strong>es 1 and 2 are usedto shunt the NWP and WP coils in the indication relays when the switch machine is unlocked.<strong>Switch</strong>es 3 and 4 are used to indicate that the switch points, switch machine, lock rod, and pointdetector rod are either in, or out of, correspondence. <strong>Switch</strong> number 5 is used for latchout.<strong>Switch</strong> 6 is used for the continuity checking LED.The range of motion for the rotary cam switch is 60 degrees. There is an external spring returnmechanism that returns the switch to the 0 degree position. As the switch rotates, the sixcontacts actuate. See Table 2-1 for detailed switch movement.Table 2-1. <strong>Switch</strong> Movement<strong>Switch</strong>Type 0° 8° 20° 21° 60°1 shunt X-------------------------X2 shunt X-------------------------X3 indicate X-------------------------X4 indicate X----------------X5 latch out X----------------------------------X6 LED X------------------------------(LED on)----------X (LED off)NOTE: X-----X = closed switch<strong>Switch</strong> 6 is used to check the mechanical interface (continuity) between the point detector switchactuating lever and rotary cam switch. When the switch machine is indicating a closed point, theLED is on and at mid-stroke the LED is off.If contacts 3, 4, and 5 are closed, the switch machine is in correspondence and the switchmachine is indicating. <strong>Switch</strong>es 3, 4, and 5 begin to open at 8 degrees. <strong>Switch</strong>es 3, 4, and 5 areopen at 20 degrees. The variance in switch closure is due to tolerances in the manufacturingprocess. <strong>Switch</strong>es 3, 4, and 5 all must be closed before the point detector system indicates.There is a range where the LED is on and the point detector is not indicating. This range occursbetween 8 degrees and 21 degrees, when one of the indicating switches (3, 4, or 5) is open andthe LED switch is closed.P2444, Rev. Jan/07 2-5ALSTOM Signaling Inc.

There are two methods to verify that the point detector is indicating.Method 11. The roller on the pivot arm is not touching the trigger on the point detector switch module.2. The LED is on.Method 21. Use a meter on TB-1, TB-2, and TB-3 to verify contact closure. Refer to schematic inAppendix A.Note: DO NOT use the LED when making point detector adjustments.The point detector module interfaces between the point detector rod, the lock rod, the cam bar,and the point detector switch module. The point detector module actuates the rotary camswitches. As the point detector rod is displaced, the pivot arm rotates and actuates the rotarycam switch. If it moves the correct amount (1/4 inch or 3/8 inch), the indication switches openand the indication is broken.The point detector system interfaces with the lock rod. There is one pin on each point detectorpivot arm that senses the position of the lock rod. If the lock rod is out of correspondence, thepin on the pivot arm does not fall into the notch on the top of the lock rod and the point detectorsystem will not indicate.The cam bar interfaces with the point detector module. The cam bar locks the Lock rod. As themachine is operated, the first thing that happens is the cam bar separates the Latchout dogs andthe pivot arms. This action rotates both rotary cam switches and thus breaks indication. Theindication is broken before the cam bar dog unlocks the lock rod. In mid-stroke, the cam barholds latchout dogs separated on the point detector module. This keeps both rotary cam switchesrotated 25 degrees. <strong>Switch</strong>es 1 and 2 stay closed and the NWP and the WP short out. As theswitch machine reaches end-of-stroke and the machine is locked, the cam bar leaves the latchoutdogs and the pivot arms rotate allowing the point detector switch module to indicate.P2444, Rev. Jan/07 2-6ALSTOM Signaling Inc.

LATCHOUTLatchout is an indication option and a mechanical memory system that stores positioninformation of points that have moved at least 1/4 inch. Latchout can be configured for 1/4 inchor 3/8 inch. This section highlights the 1/4 inch latchout. The same principles apply for 3/8 inchlatchout. Refer to the installation section of this manual for 1/4 inch versus 3/4 inchinstallations.If there is a 1/4 inch movement of the switch points in a system without latchout, the pointdetector system will not indicate. If the points close back up, the system will re-indicate.If latchout is used and there is a ¼-inch movement of the points, the point detector system willnot indicate. If the points close back up, the system will not indicate regardless of the pointposition. The system is “latched out”.There are two ways to reset the system once the system is latched out.1. Restorable latchout - The system can be reset remotely or locally. To reset the systemremotely in restorable latchout mode issue a switch call. To reset the machine locally; handthrow the machine, move the latchout dog as described in the scheduled maintenance section,or use the manual control switch. The motor will run in restorable latchout mode.2. Non-Restorable latchout - The system can only be reset locally. To reset the machine handthrow the machine or move the latchout dog as described in the scheduled maintenancesection. The motor will not run if the system is latched out in non-restorable latchout mode.As the switch points open up the point detector rod moves, as shown in Figure 2-2. Thismovement causes the pivot arms to rotate. When the switch points are open 1/4 inch, the switchmachine will not indicate. When the point detector rod moves an additional 0.045 inch, thelatchout dog drops behind the retaining ring. The retaining ring and the latchout dog keeps thepivot arm from rotating even if the points close up. Since the pivot arm cannot rotate once thesystem is latched out, the rotary cam switch contact numbers 3, 4, and 5 of the point detectorswitch module are held open. If the three rotary cam switch contacts are open, the switchmachine will not indicate.The motor is disabled if the system is latched out in non-restorable latch out mode. There arethree switches in parallel that are used to disable the amplifier. There is one switch located oneach rotary cam switch (switch number 5) and there is one switch located on the top of the pointdetector switch module (latch out switch). If the amplifier is disabled, the motor will not run. Ifone of the three switches is closed, the motor will run. If all of the switches are open, the motorwill not run.In non-restorable latchout, the motor is dependent on the position of the latchout system and theposition of the three latchout switches. The following sequence of events describes the latchoutsystem under normal operation. Refer to Figure 2-2.P2444, Rev. Jan/07 2-7ALSTOM Signaling Inc.

LATCHOUT DOGROTARYCAMSWITCHRETAININGRINGPIVOTARMPOINTDETECTORRODFigure 2-2. Latch Out Components1. The machine is at end-of-stroke (Reverse) - Latch out switch number 5 on the “reverse”rotary cam switch is closed. The motor can run.2. The machine moves to mid-stroke - The Latch out switch closes. <strong>Switch</strong> number 5 on the“reverse” and “normal” rotary cam switches open. The motor can run.3. The machine is at end-of-stroke (Normal) - Latch out switch number 5 on the “normal”rotary cam switch is closed. The motor can run.4. The points move 1/4” + 0.045” - The mechanical system latches out. <strong>Switch</strong> number 5 onthe “normal” rotary cam switch opens. (Now all three latchout switches are open.) Themotor cannot run.5. The latch out is reset - Latchout switch number 5 on the “normal” rotary cam switch closes.The motor can run.6. The machine moves to mid-stroke - The Latchout switch closes. <strong>Switch</strong> number 5 on the“normal” rotary cam switch opens. The motor can run.7. The machine is at end-of-stroke (Reverse) - Latchout switch number 5 on the “reverse”rotary cam switch is closed. The motor can run.8. The points move 1/4” + 0.045” - The mechanical system latches out. <strong>Switch</strong> number 5 onthe “reverse” rotary cam switch opens. (Now all three latchout switches are open.) Themotor cannot run.P2444, Rev. Jan/07 2-8ALSTOM Signaling Inc.

9. The latchout is reset - Latchout switch number 5 on the “reverse” rotary cam switch closes.The motor can run.In restorable latchout mode, the three parallel switches are shorted out via the latchout jumperlocated on TB1. The motor operates independently of the latch out system.P2444, Rev. Jan/07 2-9ALSTOM Signaling Inc.

THIS PAGE INTENTIONALLY LEFT BLANKP2444, Rev. Jan/07 2-10ALSTOM Signaling Inc.

SECTION 3INSTALLATIONGENERALThere are two types of GM<strong>4000</strong> switch machine installations:• A new installation• Replacement of an existing switch machineEither type of installation may be performed with or without electrical energy available foroperation of the switch machine. This Section describes both kinds of installations and therequired switch machine adjustments.Satisfactory operation of a switch layout depends on correct switch machine installation, properswitch layout adjustments, and periodic maintenance done at prescribed intervals. The ModelGM<strong>4000</strong> switch machine should be installed in accordance with the property’s approved switchlayout. Figure 3-1 shows a typical GM<strong>4000</strong> switch machine layout with the associated mountinghardware identified.THROW BARCONNECTIONHARDWARESWITCHMACHINEEXTENDEDTIESSASIBSASIBGRSRAILWAYSWITCHPOINTSSTOCKRAILLOCK ROD &POINT DETECTIONCONNECTIONHARDWAREFigure 3-1. Typical GM<strong>4000</strong> <strong>Switch</strong> LayoutP2444, Rev. Jan/07 3-1ALSTOM Signaling Inc.

PROPERTY’S REQUIREMENTSAlthough this publication provides set-up information for a typical machine installation, themaintainer should always ensure the switch layout is installed in accordance with the property'sown requirements.INSTALLATION PROCEDURESInstallation of a new switch machine or the replacement of an existing machine consists of thefollowing elements:• <strong>Switch</strong> <strong>Machine</strong> Inspection• <strong>Switch</strong> Layout (Requirements and Inspection)• <strong>Switch</strong> <strong>Machine</strong> Mounting• Electrical Wiring• <strong>Switch</strong> <strong>Machine</strong> Connecting and Adjusting• <strong>Switch</strong> <strong>Machine</strong> OperationSpecific drawings for switch machine wiring are given in Appendix A.<strong>Switch</strong> <strong>Machine</strong> InspectionThe following steps describe visual inspection of external switch machine areas. This procedureshould be performed before proceeding with the installation.1. Check the configuration of the machine being installed. If the switch machine requireschanging from left-hand to right-hand or vice versa, perform the procedure described in"Left-Hand or Right-Hand Configuration” in this Section.2. Check external surfaces for any damage (bent, cracked, or broken housings, hinges, orbrackets).3. Insure covers are installed properly and fit tightly.4. Insure wear plates are in place (in the four positions).5. Check the switch machine control requirements (either single or dual).6. Check the switch machine for proper lock rod configuration (either narrow- or widenotch).7. Check the switch machine for proper connection configuration (either spade end orthread end).8. Check the switch machine for proper connection hardware.9. Check for the required wiring harness and hardware.P2444, Rev. Jan/07 3-2ALSTOM Signaling Inc.

<strong>Switch</strong> LayoutThe following describes the installation requirements for a typical switch layout. Allrequirements should be met and checked before proceeding with the installation.A maximum clearance of 1/4 inch (less is desirable) between the throw rod and the base of thestock rail, as shown in Figure 3-2, is essential. During operation, if proper clearance is notmaintained, the points may move up relative to the stock rail (particularly if the stock rail isbeveled for AREA detail 6100 Sampson points) and pry themselves away from the stock rail.This motion may cause the point-detector rod in a switch machine to move enough to cause theindication contacts to be pushed open. The tendency of points to move up can be reduced bykeeping ballast under the ties of the switch layout firmly tamped, and maintaining properclearance.1/4" (MAX)THROWRODFigure 3-2. Throw Rod ClearanceInspection Points - The following describes the visual inspection points of a typical switchlayout. All points should be checked before proceeding with the installation.1. Inspect the heel blocks and bolts. Ensure that the thimble bolts in the heel blocks are inplace and secure.2. Check the heel block surface in relation to the switch by sighting down the rail from theheel block to switch point.3. Check that rail braces are tight and tie straps are in place and secure.4. Check all gauge plates, extension gauge plates, rail braces, and ties.5. Check that the gauge distance of 56-1/2 inches is correct at the throw-bar and lock-rodlocations.P2444, Rev. Jan/07 3-3ALSTOM Signaling Inc.

<strong>Switch</strong> <strong>Machine</strong> MountingThe two extended ties that directly support the switch machine must be reasonably straight and,where required, properly framed. All ties that support the switch machine must be well tampedfor their entire length to minimize vibration from passing trains. Also, it is important to checkthe switch layout plans to verify the installation.The stock rail and switch machine must be secured to well tamped ties, as shown in Figure 3-3,to prevent movement of the switch machine and stock rail when connected and operated. Morethan <strong>4000</strong> pounds of force can be exerted on the number one rod by the switch machine duringoperation.New Installations - Either the ALSTOM standard mounting hole pattern (3/4-inch diameter boltson 15-1/2 inch centers) or the US&S standard mounting hole pattern (7/8-inch diameter bolts on16 inch centers) can be used. Do not locate the mounting hole pattern on the ties until the switchmachine is positioned in accordance with an approved switch layout drawing.Replacement Installations - The universal mounting hole pattern interfaces with the 3/4 inchdiameter, 15-1/2 inch on center studs or bolts and 7/8 inch diameter, 16 inch on center studs orbolts.STOCKRAILMOUNTINGHOLESEXTENDEDTIES (2)SASIBSASIBGRSRAILWAYSWITCHMACHINEFigure 3-3. Typical Mounting of GM<strong>4000</strong>P2444, Rev. Jan/07 3-4ALSTOM Signaling Inc.

Electrical WiringThe switch machine has internal electrical wiring that integrates the switch machine components(switches, amplifier, LEDs, and motor) and field wiring requirements that are performed basedupon location specific conditions (supplied motor power, indication circuits, and controlcircuits). The switch machine’s internal wiring is completed in the factory with a wiring harnessand watertight connectors. Figure 3-4 identifies the internal wiring components of the GM<strong>4000</strong>switch machine. The internal wiring schematic is in Appendix A.Field WiringField wiring associated with motor power, control, and indications enter the switch machinethrough a wire entrance fitting located at either end of the switch machine (motor or detectorcompartment).Motor Power - Field wiring for motor power is connected to posts at terminal TB1 in accordancewith the detail wiring plans that apply to the location. Typical power circuits are in Appendix A.Control - Field wiring for switch machine control is connected to posts at terminal TB1 inaccordance with the detail wiring plans that apply to the location. Typical power circuits are inAppendix A.Indications - Field wiring for point-detector provided indications are connected to posts onterminals TB1, TB2, and TB3 in accordance with the detail wiring plans that apply to thelocation. Typical indication circuits are in Appendix A.P2444, Rev. Jan/07 3-5ALSTOM Signaling Inc.

TB1TB2TB4WIREENTRANCETB3WIREENTRANCEFigure 3-4. Typical GM<strong>4000</strong> Internal Wiring ComponentsMotor WiringThere are three motor wiring configurations:• 5-wire (three power lines and two auxiliary lines connected to a single AAR post)• 4-wire (two power lines and two control lines)• 3-wire (three power lines)5-wire configuration - has three power lines that are energized only when the machine isrequested to operate. The power lines are always 24 VDC, 110 VDC, or 120 VAC. These wiresare connected to TB1-1, TB1-2, and TB1-3. The throw bar travels in one direction when poweris applied to TB1-1 and TB1-2 and in the other direction when power is applied to the TB1-2 andTB1-3. The two auxiliary wires, connected to TB1-8, are common feed.4-wire configuration - has two energized power lines that can be 24 VDC, 110 VDC, or 120VAC. These wires connect to TB1-1 and TB1-3. The control lines connect to TB1-4 and TB1-5. The control lines are only energized when the machine is requested to operate.3-wire configuration - has three power lines that are energized only when the machine isrequested to operate. Power lines are always 24 VDC, 110 VDC, or 120 VAC. These wires areconnected to TB1-1, TB1-2, and TB1-3. The throw bar travels in one direction when power isapplied to TB1-1 and TB1-2 and in the other direction when power is applied to TB1-2 andTB1-3.5-wire 4-wire 3-wirePower TB1-1 TB1-1 TB1-1P2444, Rev. Jan/07 3-6ALSTOM Signaling Inc.

Power TB1-2 - TB1-2Power TB1-3 TB1-3 TB1-3Control - TB1-4 -Control - TB1-5 -Aux TB1-8 - -(2 wires)TB1TB1-8TB1-5TB1-4TB1-3TB1-2TB1-1Figure 3-5. Typical GM<strong>4000</strong> Internal Wiring Connections (TB1)To operate the switch machine using the manual switch, in the 3-, 4-, or 5-wire configuration, setthe “REMOTE/LOCAL” switch located on the amplifier to “LOCAL”. Send a request to throwthe switch machine in either direction from the control house. Operate the machine with themanual switch. After completing manual switch operation, set the “REMOTE/LOCAL” switchto “REMOTE”.P2444, Rev. Jan/07 3-7ALSTOM Signaling Inc.

Wiring ConfigurationThe machine must be configured for 3-wire (ALSTOM model 5E/5F, US&S model M23/M3),4-wire (ALSTOM model 5G/5H), or 5-wire (US&S model M23A/M23B/M3) operation via aconfiguration plug. The GM<strong>4000</strong> will not operate if the configuration plug is not installed.Speed Configuration - The default speed of the GM<strong>4000</strong> is four seconds. To configure themachine for slower speeds, install the appropriate speed select jumper located on terminal TB4,as shown in Figure 3-6.Current Configuration - The default current configuration of the GM<strong>4000</strong> is the high-currentoperation. The GM<strong>4000</strong> produces up to <strong>4000</strong> pounds of force at the end of stroke at this currentsetting. If external fuses are used to limit the current to the GM<strong>4000</strong>, they must be rated above17 amps.The GM<strong>4000</strong> can be configured for low-current operation by installing the low-current jumperon TB4. The GM<strong>4000</strong> produces up to 2800 pounds of force at the end of stroke. If externalfuses are used to limit the current to the GM<strong>4000</strong>, they must be rated above 12 amps.LOWCURRENTJUMPERTB4-1TB4-2TB4-3TB4-4TB4-5CONFIGURATIONPLUGSPEEDJUMPEROPTIONJUMPERLow Current TB4-1 to TB4-2High Current none4 sec none9 sec TB4-4 to TB4-515 sec TB4-3 to TB4-4Figure 3-6. Terminal Wiring and Configuration Plug LocationP2444, Rev. Jan/07 3-8ALSTOM Signaling Inc.

<strong>Switch</strong> <strong>Machine</strong> Connecting and AdjustingThe following describes connecting and adjusting specific switch layout hardware to the switchmachine and assumes that proper mounting of the switch machine per switch layout plan hasbeen completed together with all electrical wiring.Note: When working on machine:1. Place "LOCAL/REMOTE" switch in the “LOCAL” position.2. Rotate the hand crank cover to the open position to inhibit power to the motor.Throw RodThe following describes the throw rod connection and adjustment within a typical switch layout.Refer to Figure 3-7.Crank machine to mid-stroke position. Refer to “<strong>Switch</strong> <strong>Machine</strong> Operating - Hand Crank” inthis Section.6. If this is a dual-control machine, move the selector lever to hand-throw mode.7. Connect the throw rod clevis end to the throw bar coupler using the provided bolt, lockwasher, and nut.8. Slide the threaded end of throw rod through the “Lost Motion” basket and the connectrod to the basket using the double nuts provided.9. Place and lock the switch machine into the “Normal” position. For a dual-control switchmachine, use the hand throw; refer to “<strong>Switch</strong> <strong>Machine</strong> Operating - Hand Throw” in thisSection. For a single-control switch machine, use the hand crank or the manualoperating switch; refer to the hand crank procedure of the manual operating switchprocedure in this Section.Note: Adjust the double nuts at the switch basket if switch points close,preventing the switch machine from completing stroke.10. Adjust the double nuts at the switch basket to obtain a slight pressure condition at theclosed switch point with no visible hardware deformation.11. Secure this position using the switch basket double nuts.12. Place switch machine into “Reverse” position, using the switch machine hand throw andrepeat steps 6 and 7.13. Hand throw, hand crank, or manually operate the switch machine back and forth a fewtimes as a final check.Note: Points should fit snugly and uniformly against the stock rails without beingstressed by force from the throw bar. Excessive layout stress causes excessivewear to the switch machine.P2444, Rev. Jan/07 3-9ALSTOM Signaling Inc.

LOST MOTIONBASKETTHROWRODTHROWBARSASIBSASIBGRSRAILWAYDOUBLENUTSDOUBLENUTSFigure 3-7. Throw Rod Connection HardwareLock RodThe following describes lock rod connection and adjustment within a typical switch layout andassumes that proper throw bar connection and adjustment has been completed. Refer to Figures3-8 and 3-9.1. Move inner jam nut to end of lock rod thread (inner position).2. Position the lock rod drop lug in center of threaded Section and install outer jam nut.Figure 3-8. Lock Rod Connection HardwareP2444, Rev. Jan/07 3-10ALSTOM Signaling Inc.

4. Hand throw, crank, or manually operate the switch machine to mid-stroke position.5. Position the lock rod so that the locating marks, above notch, on the straight section, arecentered over the cam bar.6. Complete the stroke of switch machine so that the track side of the throw bar is drawninto the switch machine. Verify that the slip link of the cam bar did not separate. If itdid separate, hand throw, crank, or manually operate the switch machine to mid-stroke.This engages slip-link. Verify that locking dog on cam bar is centered through notch oflock rod.7. Assemble lock connecting rod to the front rod and the lock rod drop lug.8. Adjust drop lug height until the lock connecting rod is aligned parallel to the lock rod.9. Tighten and lock nuts at lug to keep this adjustment.10. Crank, hand throw, or manually operate machine to opposite end of stroke, but do notlock far switch point.a. Adjust the curved lock rod using double nuts so that locating marks on curvedlock rod are centered over the cam bar. Complete the locking portion of theswitch machine stroke.b. Check that the cam bar locking dog is centered in the lock rod notch.c. Tighten and lock field side lock rod nuts to keep this adjustment.11. Hand throw, crank, or manually operate the switch machine back and forth a few timesand verify that cam bar does not separate.12. Refer to the adjustments Section of this manual for the proper positioning of widenotches relative to the cam bar locking dog.CURVEDLOCK RODADJUSTINGNUTSCURVEDLOCK RODSECTIONLOCK RODLOCATINGMARKSLOCK RODNOTCHESSTRAIGHTLOCK RODSECTIONFigure 3-9. Lock Rod Features and ComponentsP2444, Rev. Jan/07 3-11ALSTOM Signaling Inc.

Connect and Initially Adjust Point-Detector RodWhen working on the machine:1. Place the "LOCAL/REMOTE" switch in the “LOCAL” position.2. Rotate the hand crank cover to the open position to inhibit power to the motor.The following describes point-detector connection and adjustment associated with wide- andnarrow-notch lock rods. These procedures assume that connection of the throw bar and lock rodto the track switch has been completed together with all electrical wiring.1. Fasten the point-detector connecting rod to the switch point lug and to the lug on thepoint-detector rod. Refer to Figure 3-10.2. Manually operate the switch machine so that the point-detector rod is drawn out from thetrack side of the switch machine to close and lock the far switch point.POINT-DETECTORROD NECKPOINT-DETECTORRODPOINT-DETECTORROD LUGPOINT-DETECTORCONNECTINGRODSWITCHPOINTLUGFigure 3-10. Point-Detector Rod Connection HardwareP2444, Rev. Jan/07 3-12ALSTOM Signaling Inc.

1. Position the spoon gauge into the necked down portion of the point-detector rod (trackside). Use either the ¼-inch end of gauge or the 3/8-inch end (whichever is required bythe railroad). Refer to Figure 3-11.Note: For narrow-notch lock rods, if a ¼-inch obstruction test is done for pointdetection, the lock rod must be disconnected (floated). For wide-notch lock rods,if the lock rod is adjusted properly, the rod does not have to be disconnected.2. Adjust position of point-detector rod at the lug end by adjusting the inner jam nut.Adjust nut until pressure of the spoon gauge against the point-detector pivot arm on thepoint-detector system module engages the track-side point-detector switch lever.Continue adjustment until the indication contacts of the rotary cam switch open(outward position). If configured with latchout, continue adjusting until the latchout dogof the point detector system engages (approximately 3/4 more of a turn), as shown inFigure 3-11.Note: Check the indication contact status of the cam switch (open or closed circuitcondition) using a meter on TB-2 or TB-3 in accordance with the field wiring.3. Tighten and lock the jam nuts that hold this adjustment. Remove the spoon gauge. Ifconfigured with latchout, verify that the cam switch indication contacts are still open.Release the latchout condition by applying a light force to the spring end of the latchoutdog.4. Crank the machine to the draw the point-detector rod into the machine.5. Position the spoon gauge in the necked down portion of the point-detector rod (fieldside). Use either the ¼-inch end of gauge or the 3/8-inch end (as required by therailroad).6. Adjust by loosening the nut and slave (1-1/8-inch open wrenches required) of the pointdetectorbar and then by screwing in or out the free end of the rod (slave). Adjust thenut until the pressure of the spoon gauge against the point-detector pivot arm on thepoint-detector system module engages the field side point-detector switch lever.Continue the adjustment until the cam switch indication contacts open (outwardposition). If configured with latchout, continue adjusting until the latchout dog of thepoint-detector system engages (approximately a additional 3/4 turn).Note: Check cam switch indication contact status (open or closed circuit condition)using a meter on TB-2 or TB-3 in accordance with the field wiring for location.7. Hold this position by screwing in the free end of point-detector rod. Remove the spoongauge and release the latched out condition by applying a light force to the spring end ofthe latchout dog.8. After making adjustments in both directions, manually the operate machine back andforth a few times. Check that the point-detector pivot arm engages the associated trackP2444, Rev. Jan/07 3-13ALSTOM Signaling Inc.