Ships of the Year

Ships of the Year

Ships of the Year

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

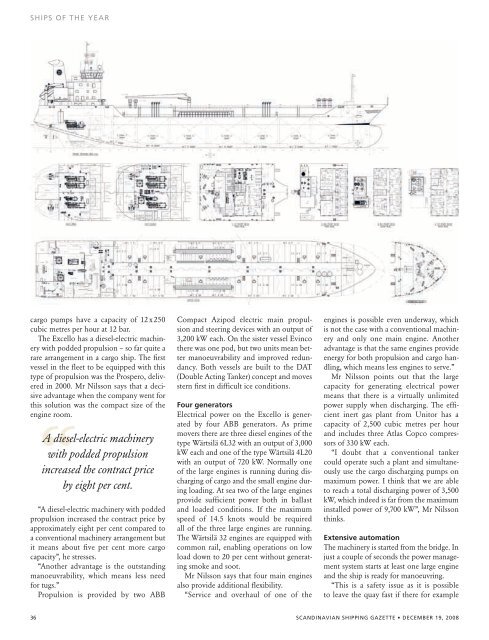

SHIPS OF THE YEAR<br />

cargo pumps have a capacity <strong>of</strong> 12 x 250<br />

cubic metres per hour at 12 bar.<br />

The Excello has a diesel-electric machinery<br />

with podded propulsion – so far quite a<br />

rare arrangement in a cargo ship. The first<br />

vessel in <strong>the</strong> fleet to be equipped with this<br />

type <strong>of</strong> propulsion was <strong>the</strong> Prospero, delivered<br />

in 2000. Mr Nilsson says that a decisive<br />

advantage when <strong>the</strong> company went for<br />

this solution was <strong>the</strong> compact size <strong>of</strong> <strong>the</strong><br />

engine room.<br />

A diesel-electric machinery<br />

with podded propulsion<br />

increased <strong>the</strong> contract price<br />

by eight per cent.<br />

“A diesel-electric machinery with podded<br />

propulsion increased <strong>the</strong> contract price by<br />

approximately eight per cent compared to<br />

a conventional machinery arrangement but<br />

it means about five per cent more cargo<br />

capacity”, he stresses.<br />

“Ano<strong>the</strong>r advantage is <strong>the</strong> outstanding<br />

manoeuvrability, which means less need<br />

for tugs.”<br />

Propulsion is provided by two ABB<br />

Compact Azipod electric main propulsion<br />

and steering devices with an output <strong>of</strong><br />

3,200 kW each. On <strong>the</strong> sister vessel Evinco<br />

<strong>the</strong>re was one pod, but two units mean better<br />

manoeuvrability and improved redundancy.<br />

Both vessels are built to <strong>the</strong> DAT<br />

(Double Acting Tanker) concept and moves<br />

stern first in difficult ice conditions.<br />

Four generators<br />

Electrical power on <strong>the</strong> Excello is generated<br />

by four ABB generators. As prime<br />

movers <strong>the</strong>re are three diesel engines <strong>of</strong> <strong>the</strong><br />

type Wärtsilä 6L32 with an output <strong>of</strong> 3,000<br />

kW each and one <strong>of</strong> <strong>the</strong> type Wärtsilä 4L20<br />

with an output <strong>of</strong> 720 kW. Normally one<br />

<strong>of</strong> <strong>the</strong> large engines is running during discharging<br />

<strong>of</strong> cargo and <strong>the</strong> small engine during<br />

loading. At sea two <strong>of</strong> <strong>the</strong> large engines<br />

provide sufficient power both in ballast<br />

and loaded conditions. If <strong>the</strong> maximum<br />

speed <strong>of</strong> 14.5 knots would be required<br />

all <strong>of</strong> <strong>the</strong> three large engines are running.<br />

The Wärtsilä 32 engines are equipped with<br />

common rail, enabling operations on low<br />

load down to 20 per cent without generating<br />

smoke and soot.<br />

Mr Nilsson says that four main engines<br />

also provide additional flexibility.<br />

“Service and overhaul <strong>of</strong> one <strong>of</strong> <strong>the</strong><br />

engines is possible even underway, which<br />

is not <strong>the</strong> case with a conventional machinery<br />

and only one main engine. Ano<strong>the</strong>r<br />

advantage is that <strong>the</strong> same engines provide<br />

energy for both propulsion and cargo handling,<br />

which means less engines to serve.”<br />

Mr Nilsson points out that <strong>the</strong> large<br />

capacity for generating electrical power<br />

means that <strong>the</strong>re is a virtually unlimited<br />

power supply when discharging. The efficient<br />

inert gas plant from Unitor has a<br />

capacity <strong>of</strong> 2,500 cubic metres per hour<br />

and includes three Atlas Copco compressors<br />

<strong>of</strong> 330 kW each.<br />

“I doubt that a conventional tanker<br />

could operate such a plant and simultaneously<br />

use <strong>the</strong> cargo discharging pumps on<br />

maximum power. I think that we are able<br />

to reach a total discharging power <strong>of</strong> 3,500<br />

kW, which indeed is far from <strong>the</strong> maximum<br />

installed power <strong>of</strong> 9,700 kW”, Mr Nilsson<br />

thinks.<br />

Extensive automation<br />

The machinery is started from <strong>the</strong> bridge. In<br />

just a couple <strong>of</strong> seconds <strong>the</strong> power management<br />

system starts at least one large engine<br />

and <strong>the</strong> ship is ready for manoeuvring.<br />

“This is a safety issue as it is possible<br />

to leave <strong>the</strong> quay fast if <strong>the</strong>re for example<br />

36 SCANDINAVIAN SHIPPING GAZETTE • DECEMBER 19, 2008