Ships of the Year

Ships of the Year

Ships of the Year

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

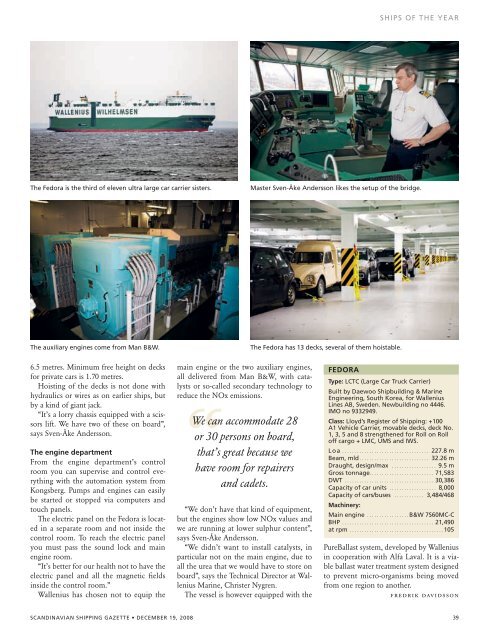

The Fedora is <strong>the</strong> third <strong>of</strong> eleven ultra large car carrier sisters.<br />

Master Sven-Åke Andersson likes <strong>the</strong> setup <strong>of</strong> <strong>the</strong> bridge.<br />

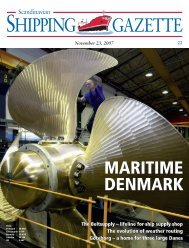

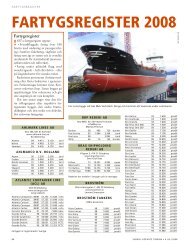

The auxiliary engines come from Man B&W. The Fedora has 13 decks, several <strong>of</strong> <strong>the</strong>m hoistable.<br />

6.5 metres. Minimum free height on decks<br />

for private cars is 1.70 metres.<br />

Hoisting <strong>of</strong> <strong>the</strong> decks is not done with<br />

hydraulics or wires as on earlier ships, but<br />

by a kind <strong>of</strong> giant jack.<br />

“It’s a lorry chassis equipped with a scissors<br />

lift. We have two <strong>of</strong> <strong>the</strong>se on board”,<br />

says Sven-Åke Andersson.<br />

The engine department<br />

From <strong>the</strong> engine department’s control<br />

room you can supervise and control everything<br />

with <strong>the</strong> automation system from<br />

Kongsberg. Pumps and engines can easily<br />

be started or stopped via computers and<br />

touch panels.<br />

The electric panel on <strong>the</strong> Fedora is located<br />

in a separate room and not inside <strong>the</strong><br />

control room. To reach <strong>the</strong> electric panel<br />

you must pass <strong>the</strong> sound lock and main<br />

engine room.<br />

“It’s better for our health not to have <strong>the</strong><br />

electric panel and all <strong>the</strong> magnetic fields<br />

inside <strong>the</strong> control room.”<br />

Wallenius has chosen not to equip <strong>the</strong><br />

main engine or <strong>the</strong> two auxiliary engines,<br />

all delivered from Man B&W, with catalysts<br />

or so-called secondary technology to<br />

reduce <strong>the</strong> NOx emissions.<br />

We can accommodate 28<br />

or 30 persons on board,<br />

that’s great because we<br />

have room for repairers<br />

and cadets.<br />

“We don’t have that kind <strong>of</strong> equipment,<br />

but <strong>the</strong> engines show low NOx values and<br />

we are running at lower sulphur content”,<br />

says Sven-Åke Andersson.<br />

“We didn’t want to install catalysts, in<br />

particular not on <strong>the</strong> main engine, due to<br />

all <strong>the</strong> urea that we would have to store on<br />

board”, says <strong>the</strong> Technical Director at Wallenius<br />

Marine, Christer Nygren.<br />

The vessel is however equipped with <strong>the</strong><br />

FEDORA<br />

SHIPS oF THE YEAR<br />

Type: LCTC (Large Car Truck Carrier)<br />

Built by Daewoo Shipbuilding & Marine<br />

Engineering, South korea, for Wallenius<br />

Lines AB, Sweden. Newbuilding no 4446.<br />

IMo no 9332949.<br />

Class: Lloyd’s Register <strong>of</strong> Shipping: +100<br />

A1 Vehicle Carrier, movable decks, deck No.<br />

1, 3, 5 and 8 streng<strong>the</strong>ned for Roll on Roll<br />

<strong>of</strong>f cargo + LMC, UMS and IWS.<br />

L o a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227.8 m<br />

Beam, mld . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.26 m<br />

Draught, design/max . . . . . . . . . . . . . . . . . . 9.5 m<br />

Gross tonnage. . . . . . . . . . . . . . . . . . . . . . . . . . 71,583<br />

DWT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30,386<br />

Capacity <strong>of</strong> car units . . . . . . . . . . . . . . . . . . . 8,000<br />

Capacity <strong>of</strong> cars/buses . . . . . . . . . . . . 3,484/468<br />

Machinery:<br />

Main engine . . . . . . . . . . . . . . . . . B&W 7S60MC-C<br />

BHP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21,490<br />

at rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105<br />

PureBallast system, developed by Wallenius<br />

in cooperation with Alfa Laval. It is a viable<br />

ballast water treatment system designed<br />

to prevent micro-organisms being moved<br />

from one region to ano<strong>the</strong>r.<br />

fredrik davidsson<br />

SCANDINAVIAN SHIPPING GAZETTE • DECEMBER 19, 2008 39