Complete (13 MB) - Chris Alston's Chassisworks

Complete (13 MB) - Chris Alston's Chassisworks

Complete (13 MB) - Chris Alston's Chassisworks

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

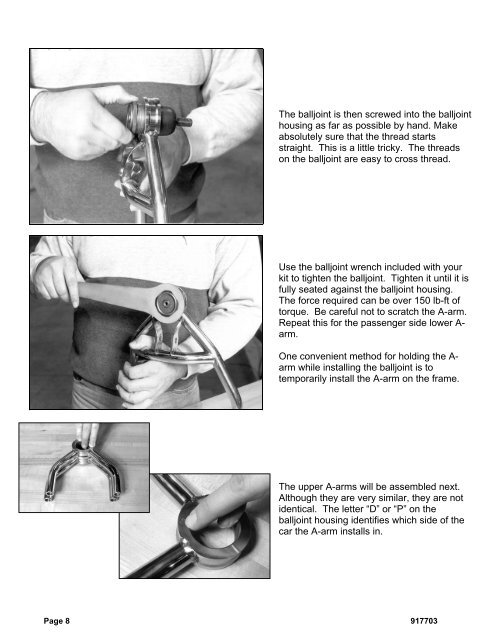

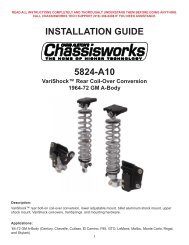

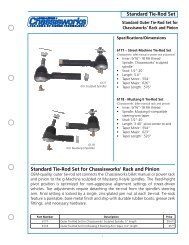

The balljoint is then screwed into the balljointhousing as far as possible by hand. Makeabsolutely sure that the thread startsstraight. This is a little tricky. The threadson the balljoint are easy to cross thread.Use the balljoint wrench included with yourkit to tighten the balljoint. Tighten it until it isfully seated against the balljoint housing.The force required can be over 150 lb-ft oftorque. Be careful not to scratch the A-arm.Repeat this for the passenger side lower A-arm.One convenient method for holding the A-arm while installing the balljoint is totemporarily install the A-arm on the frame.The upper A-arms will be assembled next.Although they are very similar, they are notidentical. The letter “D” or “P” on theballjoint housing identifies which side of thecar the A-arm installs in.Page 8 917703