FLEX CIRCUITS DESIGN GUIDE

Minco Flex Circuits Design Guide - BiS Sistem

Minco Flex Circuits Design Guide - BiS Sistem

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Glossary<br />

Impedance<br />

The measurement in ohms of the apparent resistance of an AC<br />

circuit. Impedance depends on several factors: DC resistance,<br />

capacitance, inductance of the line, the width of the conductor<br />

strands, and the conductor spacing relative to ground and insulating<br />

layers.<br />

Major access hole<br />

An access hole (see “Access hole”) that is large enough to<br />

expose a major portion of a conductor pad, which is usually<br />

coated with solder.<br />

Major<br />

Access Hole<br />

Minor access hole<br />

An access hole (see “Access hole”) that exposes only a very small<br />

portion of a conductor pad, used on holes where a solder pad is<br />

not needed or desired. The cover hole must still be larger than<br />

the through-hole to allow for normal registration tolerances.<br />

Minor<br />

Access Hole<br />

Pad<br />

The portion of a conductor, usually surrounding a through-hole,<br />

that is used to connect a component for an electrical connection.<br />

Pads are sometimes referred to as “terminals” or “lands.”<br />

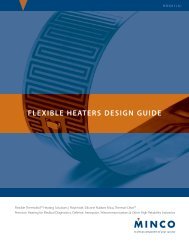

Profile tolerance<br />

Dimensional tolerancing where the part trim line is contained<br />

within a tolerance zone consisting of the area between two parallel<br />

lines, separated by the specified tolerance. For example, a<br />

circuit to be trimmed with a steel rule die might have a tolerance<br />

of 0.015" (0.38mm) (A 0.030"/0.76mm wide profile tolerance<br />

zone). The circuit trim line could vary anywhere inside the<br />

zone.<br />

A<br />

Pad<br />

DRAWING CALLOUT<br />

.030" (0.76mm) A B<br />

B<br />

NOMINAL TRIM LINE<br />

Nesting<br />

Designing circuits so that they lay closely together on a panel<br />

during production. This maximizes the usage of panel space,<br />

which minimizes production cost.<br />

EXAMPLE<br />

.030" (0.76mm) WIDE<br />

TOLERANCE ZONE<br />

Punch-and-die<br />

Hard-tooling that is used in a punch press. A punch-and-die<br />

consists of two precisely matched metal plates held in special<br />

die shoes. When the punch press is activated, the plates come<br />

together in order to punch a specific pattern into material.<br />

29