- Page 1 and 2:

Comprehensive Report of the Special

- Page 3 and 4:

Iraq’s Chemical Warfare Program B

- Page 5 and 6:

Contents Key Findings..............

- Page 7 and 8:

Key Findings Saddam never abandoned

- Page 9 and 10:

• Uday—head of the Fedayeen Sad

- Page 11 and 12:

Evolution of the Chemical Warfare P

- Page 13 and 14:

Chemical Figure 1. CW facilities as

- Page 15 and 16:

• Iraq also declared that by 1989

- Page 17 and 18:

in April 1991, the UN adopted Secur

- Page 19 and 20:

Reports of an unexplained discovery

- Page 21 and 22:

• With the exception of one insta

- Page 23 and 24:

In subsequent years, and in part tr

- Page 25 and 26:

• ISG has been unable to establis

- Page 27 and 28:

Iraq’s Declared Work With VX Nerv

- Page 29 and 30:

Infrastructure—Production Capabil

- Page 31 and 32:

imported anhydrous chlorine gas fro

- Page 33 and 34:

• Less corrosion resistant equipm

- Page 35 and 36:

Weaponization Iraq’s capability t

- Page 37 and 38:

Post-OIF Insurgent Attempts to Tap

- Page 39 and 40:

VX Weaponization Iraq had not adequ

- Page 41 and 42:

• ISG investigation of eight ASPs

- Page 43 and 44:

• The amount of inspections ISG w

- Page 45 and 46:

An Najaf Depot Az Zubayr Depot Taji

- Page 47 and 48:

Depot Name Pre-OIF “Indicators”

- Page 49 and 50:

Annex A IIS Undeclared Research on

- Page 51 and 52:

• A former Iraqi intelligence off

- Page 53 and 54:

The absence of laboratory equipment

- Page 55 and 56:

• The April 2003 exploitation tea

- Page 57 and 58:

• The IIS M16 laboratory located

- Page 59 and 60:

Site exploitations have verified th

- Page 61 and 62:

Iraqi Regime Use of Poisons and Tox

- Page 63 and 64:

Figure 20. Various buried chemicals

- Page 65 and 66:

Figure 22. Tank of triethylamine re

- Page 67 and 68:

Annex B Al Muthanna Chemical Weapon

- Page 69 and 70:

life, and the precursor compound cy

- Page 71 and 72:

Table 1. Project 922, declared prod

- Page 73 and 74:

Figure 2. Al Muthanna R&D/Laborator

- Page 75 and 76:

Figure 4. Al Muthanna pilot plants

- Page 77 and 78:

Figure 5. Munitions storage area. C

- Page 79 and 80:

Removed By Iraqis During OIF Figure

- Page 81 and 82:

Figure 8. Al Muthanna administratio

- Page 83 and 84:

Figure 10. Complete excavation and

- Page 85 and 86:

• Drums and debris were visually

- Page 87 and 88:

• Cages that once housed animals

- Page 89 and 90:

Figure 18. Mangled and rusted munit

- Page 91 and 92:

Annex C The Iraqi Industrial Commit

- Page 93 and 94:

MIC and MIM: Key Players in Iraq’

- Page 95 and 96:

Annex D Tariq Company’s Activitie

- Page 97 and 98:

chlorine production had stopped mon

- Page 99 and 100:

Summary Annex E Al-Abud Network Tri

- Page 101 and 102:

Ties to the Former Regime Implicati

- Page 103 and 104:

Annex F Detailed Preliminary Assess

- Page 105 and 106:

16 May 2004: 152mm Binary Chemical

- Page 107 and 108:

Origin of the Binary Sarin Round Us

- Page 109 and 110:

Figure 5. Examples of the 10 155mm

- Page 111 and 112:

Figure 9. Additional SAKR-18 rocket

- Page 113 and 114:

Biological Regime Strategic Intent

- Page 115 and 116:

Contents Key Findings..............

- Page 117 and 118:

Key Findings The Biological Warfare

- Page 119 and 120:

• Similarly, ISG found no informa

- Page 121 and 122:

Evolution of the Biological Warfare

- Page 123 and 124:

Figure 1. Some major sites associat

- Page 125 and 126:

Rihab formed a team and commenced e

- Page 127 and 128:

• The Iraqis were well aware of t

- Page 129 and 130:

who ordered the vials destroyed. Dr

- Page 131 and 132:

to BW than biopesticides. ISG has l

- Page 133 and 134:

• In the chemical field, ISG lear

- Page 135 and 136:

experiments and stored WMD precurso

- Page 137 and 138:

ISG continued to gain more insight

- Page 139 and 140:

mid-level scientist who worked at s

- Page 141 and 142:

• During the approximate period o

- Page 143 and 144:

Iraq’s viral BW program began its

- Page 145 and 146:

cally looted post-OIF (see below, u

- Page 147 and 148:

Iraqi Retention of Smallpox Culture

- Page 149 and 150: Bacillus thuringiensis (Bt) Bt is a

- Page 151 and 152: Figure 7. Example of dual-use biolo

- Page 153 and 154: Drying Process/Carrier/Particle Siz

- Page 155 and 156: tank was used only for storage and

- Page 157 and 158: Figure 9. Sign at the entrance to F

- Page 159 and 160: Two 1,000-liter, stirred, jacketed

- Page 161 and 162: Weaponization Between the late 1980

- Page 163 and 164: use with either a chemical or a BW

- Page 165 and 166: Concealment And Destruction of Biol

- Page 167 and 168: • Former MIC director ‘Amir Ras

- Page 169 and 170: • The amount of each agent produc

- Page 171 and 172: Detailed Accounting of Iraq’s R-4

- Page 173 and 174: Despite an extensive interview prog

- Page 175 and 176: Figure 13. 1m 3 Stainless steel mob

- Page 177 and 178: Background Annex A Bulk BW Agents U

- Page 179 and 180: Annex B BW Research and Development

- Page 181 and 182: Al Hamath The Al Hamath facility wa

- Page 183 and 184: Al Kindi Company for Veterinary Vac

- Page 185 and 186: • All buildings, which were found

- Page 187 and 188: Figure 4. Two 1,000-liter, stirred,

- Page 189 and 190: Annex C ISG Investigation of Iraq

- Page 191 and 192: ate the claim of a mobile BW progra

- Page 193 and 194: of accommodating rail cars. However

- Page 195 and 196: Annex D Trailers Suspected of Being

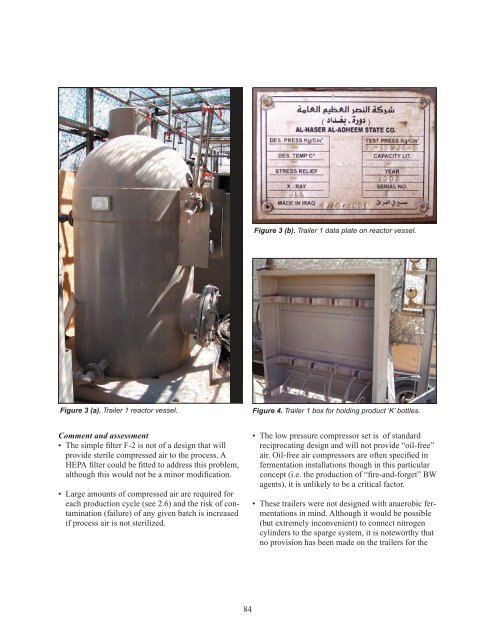

- Page 197 and 198: Present Fermentor Design Feature Cr

- Page 199: do. In summary, their conclusion is

- Page 203 and 204: • During the production cycle, ve

- Page 205 and 206: Figure 8. Solids in the bottom of t

- Page 207 and 208: • Process was skid mounted and wa

- Page 209 and 210: • Clear operating instructions to

- Page 211 and 212: Figure 9. Process fl ow diagram of

- Page 213 and 214: • Undated Republican Guard Report

- Page 215 and 216: Glossary and Acronyms Term or Acron

- Page 217 and 218: CCHF Crimean Congo Hemorrhagic Feve

- Page 219 and 220: End User EOD EP ETGC EU EUC EW FAE

- Page 221 and 222: HTPB HUMINT HVD IAEA IAEC IAF IAH I

- Page 223 and 224: M18 M19 M20 M21 M22 M23 M40 MABOT M

- Page 225 and 226: Oil for Food Program OMI OMV ONAREM

- Page 227 and 228: SME SOE SOMO SOTI SPO SRBM SRC SRG

- Page 229 and 230: UNSCR UNSCR UNSYG UO2 UO4 UoB URENC

- Page 231: This page intentionally left blank.