Comprehensive Report

GPO-DUELFERREPORT-3

GPO-DUELFERREPORT-3

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Figure 8. Solids in the bottom of the<br />

reactor vessel on trailer 1.<br />

Figure 7. Outlet valve and pipe on<br />

the reactor vessel of trailer 1.<br />

never be completely emptied. To carry over some<br />

of the culture to the next production cycle will<br />

not cause any problem (apart from a reduction in<br />

productivity) so long as the culture remains sterile.<br />

Where it is critical is in the event of a contaminated<br />

or failed batch. Removing by hand the highly toxic<br />

remnants of the failed batch from the reactor would<br />

be no easy task. At Al Hakam, Iraq’s principal BW<br />

facility, the production run failure rate was reported<br />

as running at 10 to 20 per cent. The production conditions<br />

were far better than they would be on these<br />

trailers, so ISG would anticipate high failure rates<br />

using this process as a mobile BW agent production<br />

platform.<br />

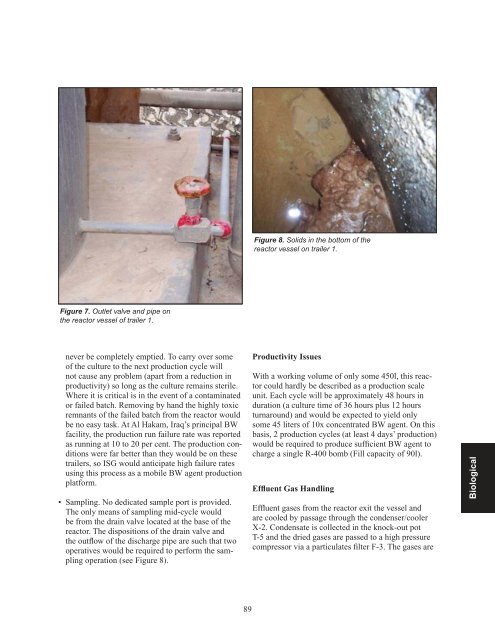

• Sampling. No dedicated sample port is provided.<br />

The only means of sampling mid-cycle would<br />

be from the drain valve located at the base of the<br />

reactor. The dispositions of the drain valve and<br />

the outflow of the discharge pipe are such that two<br />

operatives would be required to perform the sampling<br />

operation (see Figure 8).<br />

Productivity Issues<br />

With a working volume of only some 450l, this reactor<br />

could hardly be described as a production scale<br />

unit. Each cycle will be approximately 48 hours in<br />

duration (a culture time of 36 hours plus 12 hours<br />

turnaround) and would be expected to yield only<br />

some 45 liters of 10x concentrated BW agent. On this<br />

basis, 2 production cycles (at least 4 days’ production)<br />

would be required to produce sufficient BW agent to<br />

charge a single R-400 bomb (Fill capacity of 90l).<br />

Effluent Gas Handling<br />

Effluent gases from the reactor exit the vessel and<br />

are cooled by passage through the condenser/cooler<br />

X-2. Condensate is collected in the knock-out pot<br />

T-5 and the dried gases are passed to a high pressure<br />

compressor via a particulates filter F-3. The gases are<br />

Biological<br />

89